Production equipment and process for HDPE furniture material based on CaCO3 nano SiO2 modification

A production equipment and modification technology, which is applied in the field of injection molding and spray-plastic furniture raw material preparation, can solve the problems of not achieving anti-aging, no preparation equipment, and no manipulator to improve the physical properties of furniture materials, so as to improve uniformity and density. , the effect of increasing the density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

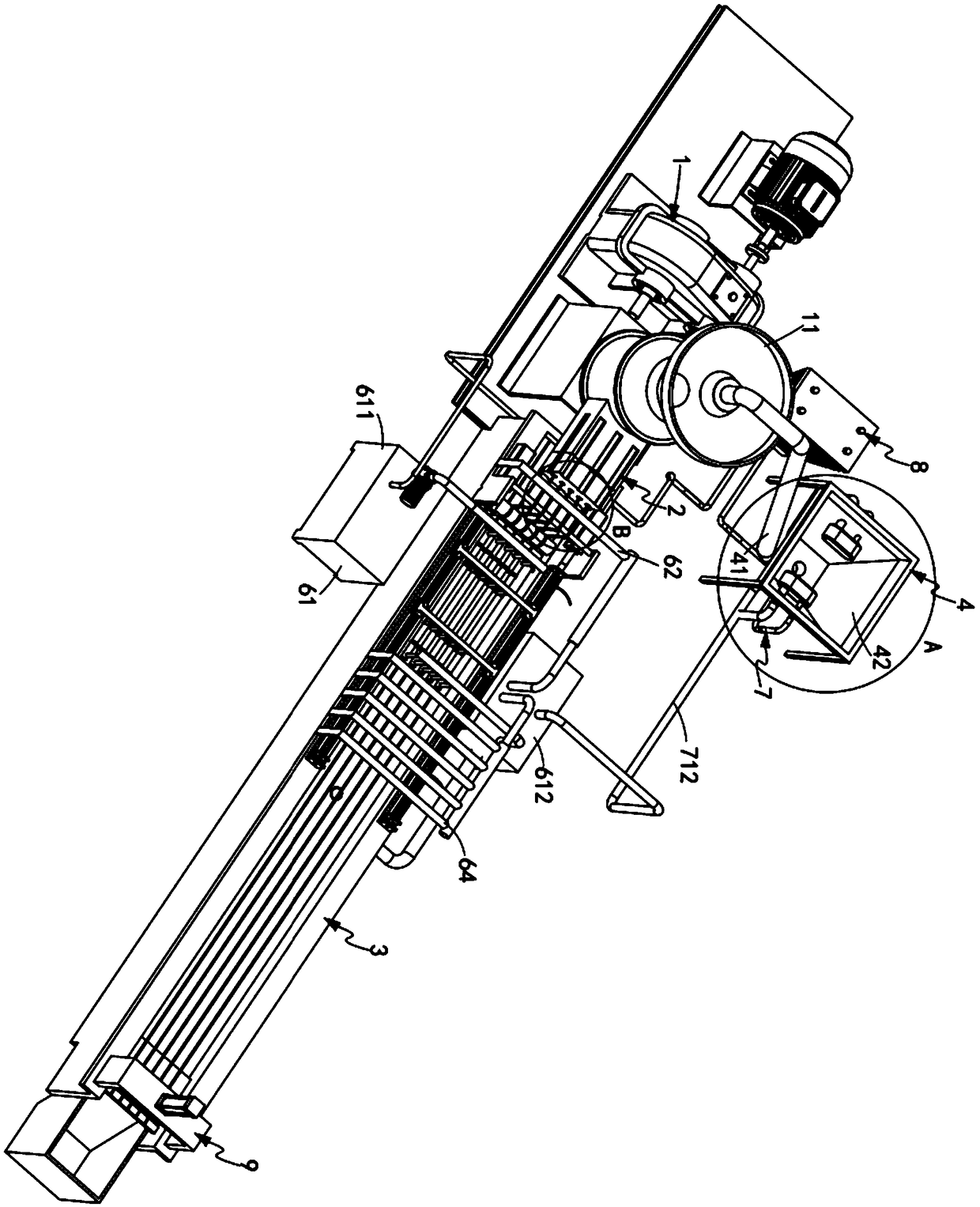

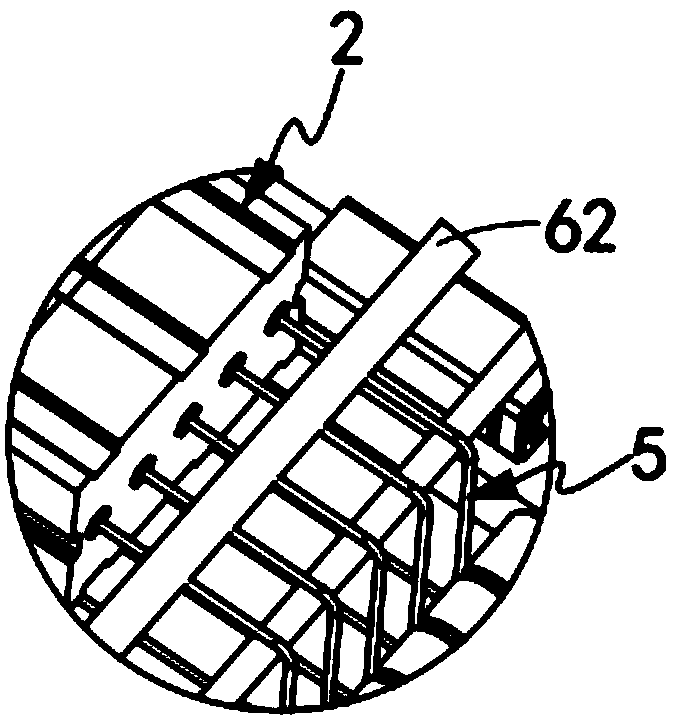

[0070] Such as figure 1 , figure 2 and image 3 Shown, a kind of production equipment based on CaCO3 nano-SiO2 modified HDPE furniture materials, including banburying device 1, die set 2, cooling tank 3 and screw conveyor 4, said die set 2 is arranged on said close On the refining device 1, and it is located at the feed end of the cooling tank 3, the strip material 5 formed by the die set 2 is conveyed in the cooling tank 3, and the screw conveyor 4 is arranged on the internal mixing One side of the device 1, the discharge end of the screw feeding pipe 51 at the bottom is arranged directly above the feed hopper 11 of the banburying device 1, and also includes:

[0071] The dense cooler 6, the dense cooler 6 is arranged at the feeding end of the cooling tank 3, which includes cooling machines 61 arranged on both sides of the cooling tank 3 and arranged in sequence along the feeding direction of the cooling tank 3 The pre-cooling pipe 62, the dense cooling mechanism 63, and ...

Embodiment 2

[0122] Reference Example 1, a production process based on CaCO3 nano-SiO2 modified HDPE furniture material.

[0123] Such as Figure 17 Shown, a kind of based on CaCO Nano SiO The production technique of the HDPE furniture material of modification, it is characterized in that, comprises the following steps:

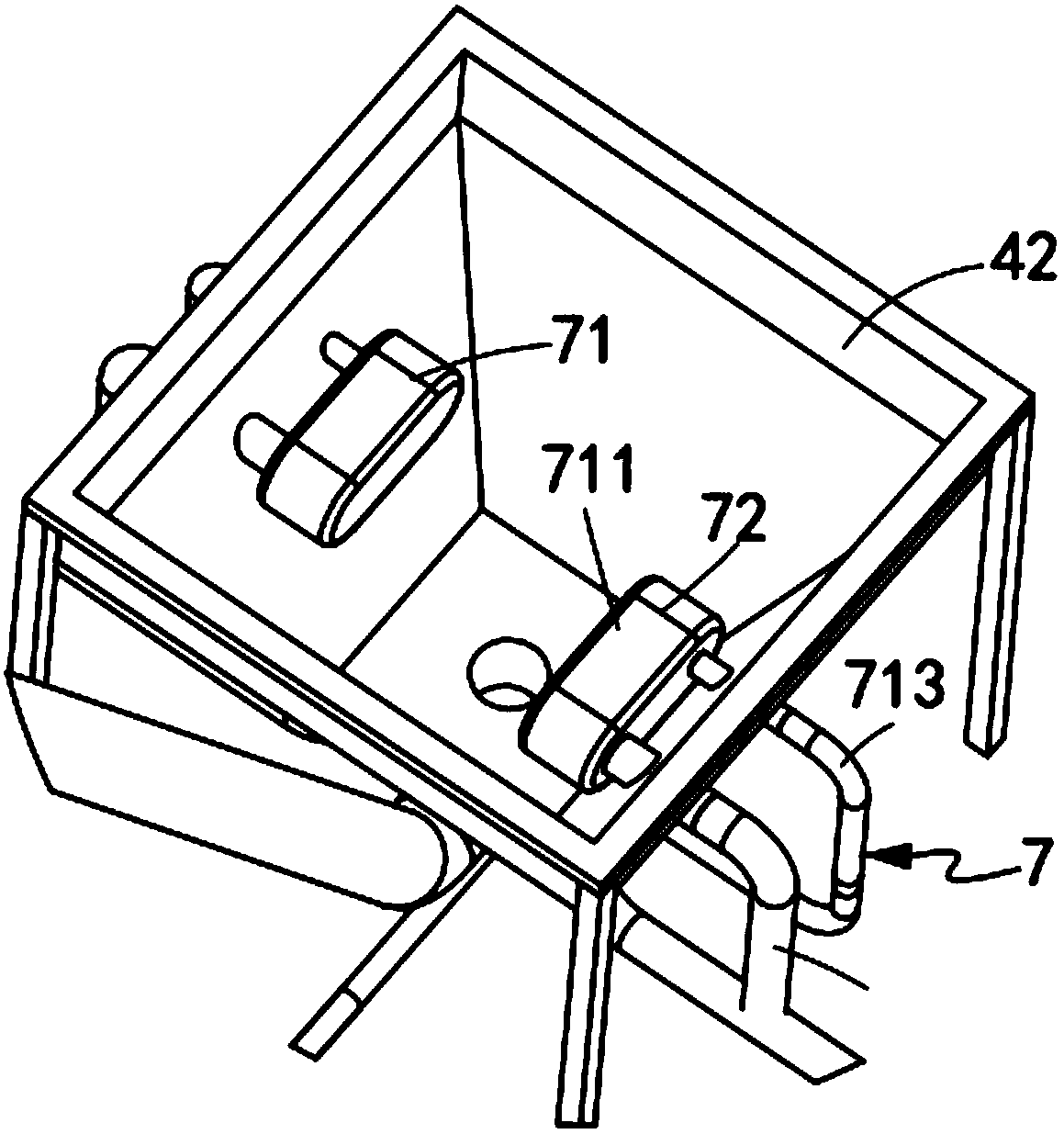

[0124] Step 1, the mixing process, the modifier and raw materials are poured into the hopper 42 for mixing, and after mixing evenly, the screw feeding pipe 51 located below the hopper 42 is lifted and transported to the feeder of the banburying device 1 located on the side of the hopper 42. Inside the hopper 11;

[0125] Step 2, banburying process, the mixture of modifier and HDPE input into the feed hopper 11 is smelted by the banburying device 1, and the strip material 5 is formed by the output of the die set 2 after smelting;

[0126] Step 3, pre-cooling process, after the formed strip material 5 is input into the cooling tank 3, it is transported along the length dire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com