Welding frame of spot welding machine

A technology of spot welding machine and welding frame, which is applied in the direction of welding equipment, welding equipment, resistance welding equipment, etc., can solve the problems of not conforming to modern industrial production, high labor intensity of workers, low welding pass rate, etc., and achieve spot welding welding process The effect of stability, simple structure and low input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

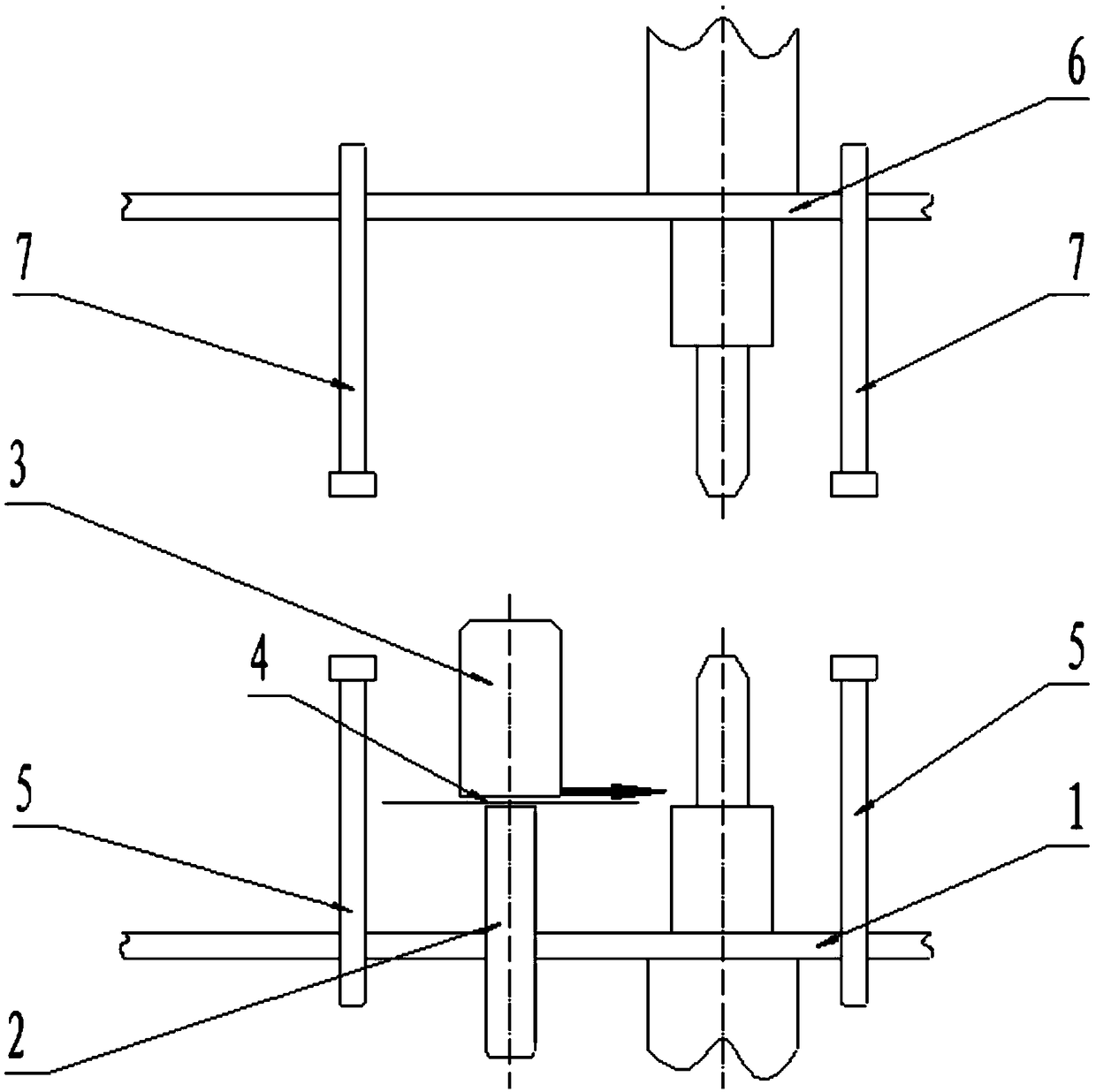

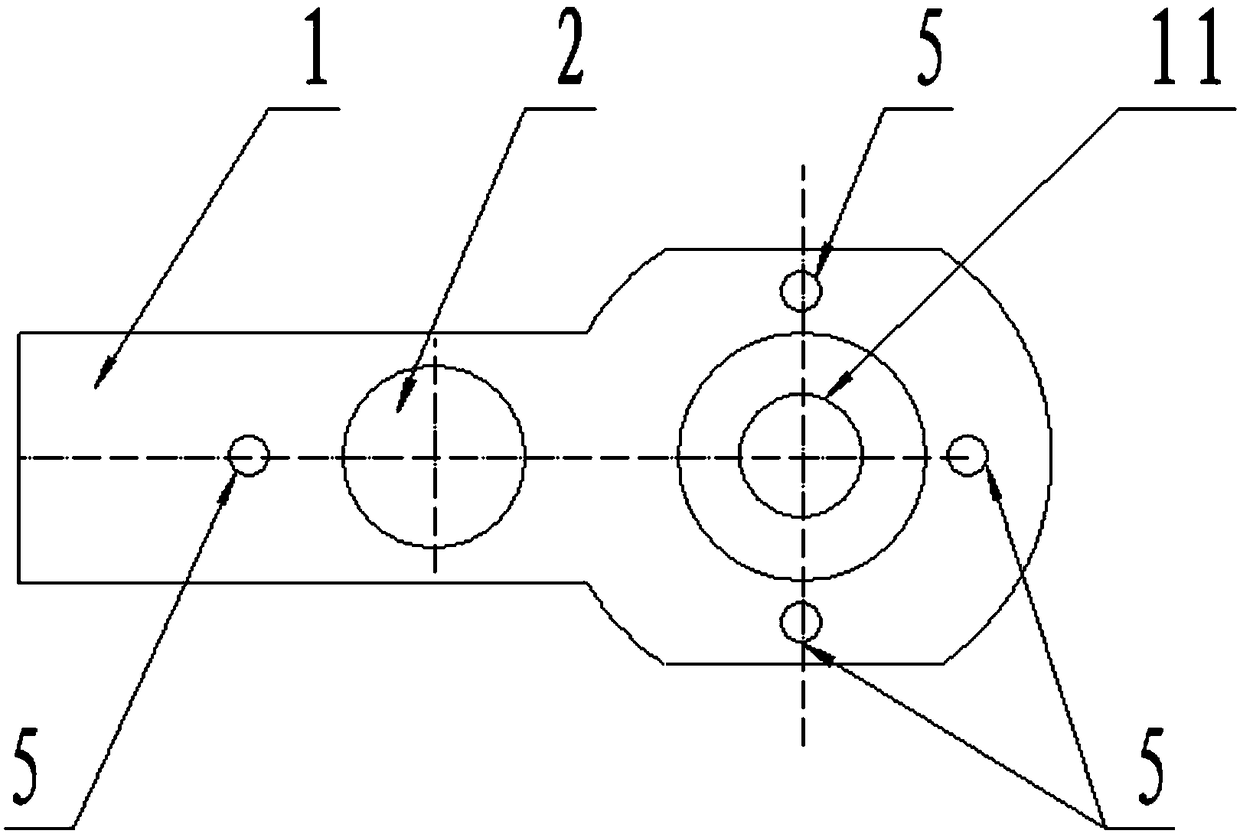

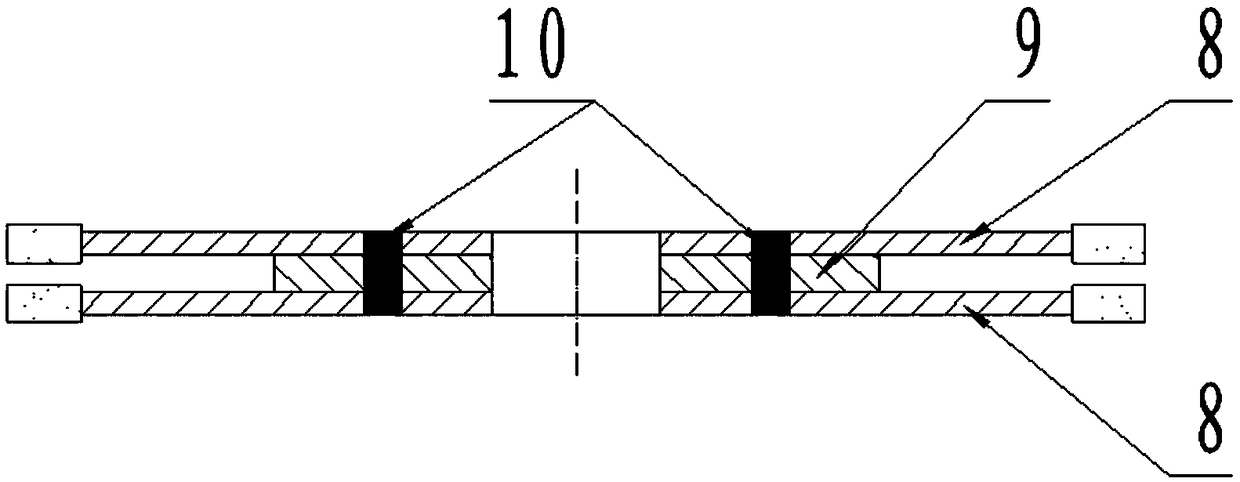

[0038] The present invention comprises a lower base 1 , a support column 2 , a rotating fixed shaft 3 , a dial 4 , a lower pressing block 5 , an upper base 6 , and an upper pressing block 7 . Both the lower base 1 and the upper base 6 are made of tool steel, the lower base 1 is fixed on the lower welding head 11 of the spot welding machine; the upper base 6 is fixed on the upper welding head of the spot welding machine; the support column 2 is installed on the lower base 1 , can adjust the distance with the upper welding head, and can fix the position; the rotating fixed shaft 3 is made of insulating bakelite, is coaxially connected with the support column 2 through the bearing, and can rotate freely; the dial 4 is fixed on the rotating fixed shaft 3, record the rotation angle of the rotating fixed shaft 3; the lower pressing block 5 and the upper pressing block 7 are both made of high elastic rubber and stainless steel columns, the lower pressing block 5 is installed on the lo...

example 1

[0056] The product Φ125D produces double-layer slotted pieces, the thickness of the middle welding piece is 2.0mm, and the outer diameter of the welding piece is Φ65mm. A total of 105 pieces are required to be produced. Debug the equipment according to the drawings and process requirements, and start spot welding. It took a total of 1.5 hours. After inspection, there were no defective products such as weak welding and deviation of solder joints. There was no deviation in the depth and size of solder joints, and the pass rate was 100%. The production test proves that the equipment of the invention can fully meet the needs of batch production, and the equipment input cost is low and the efficiency is high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com