Thread molding unit and reinforcing steel bar end thread machining tool

A technology for forming units and threads, which is applied to threaded products, other household appliances, household appliances, etc., can solve the problems of high labor intensity, reduced connection strength, internal mechanical strain, etc., to reduce labor intensity and improve tensile strength. The effect of strength, high practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in combination with specific implementation methods and accompanying drawings.

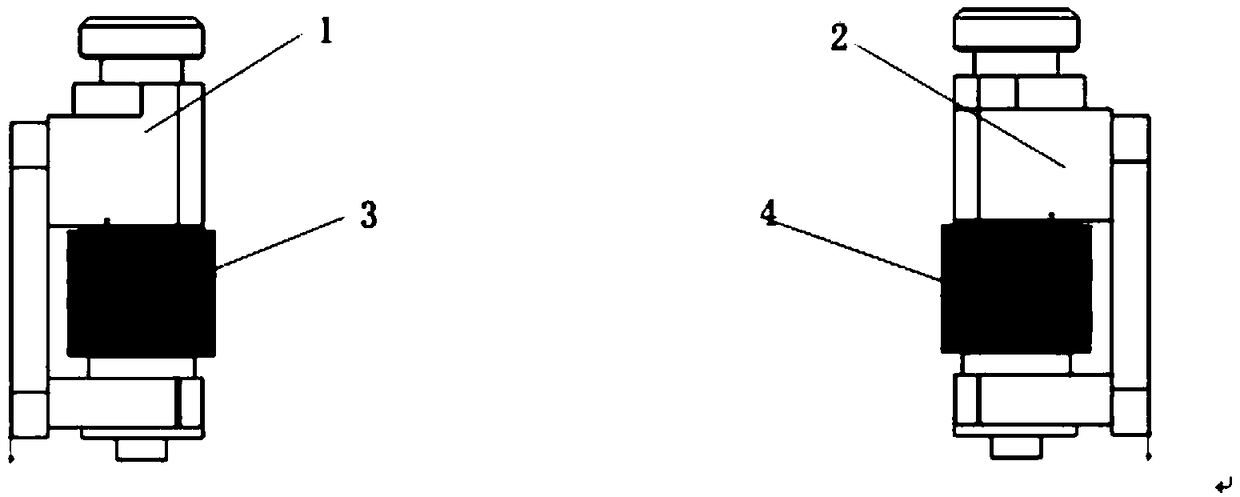

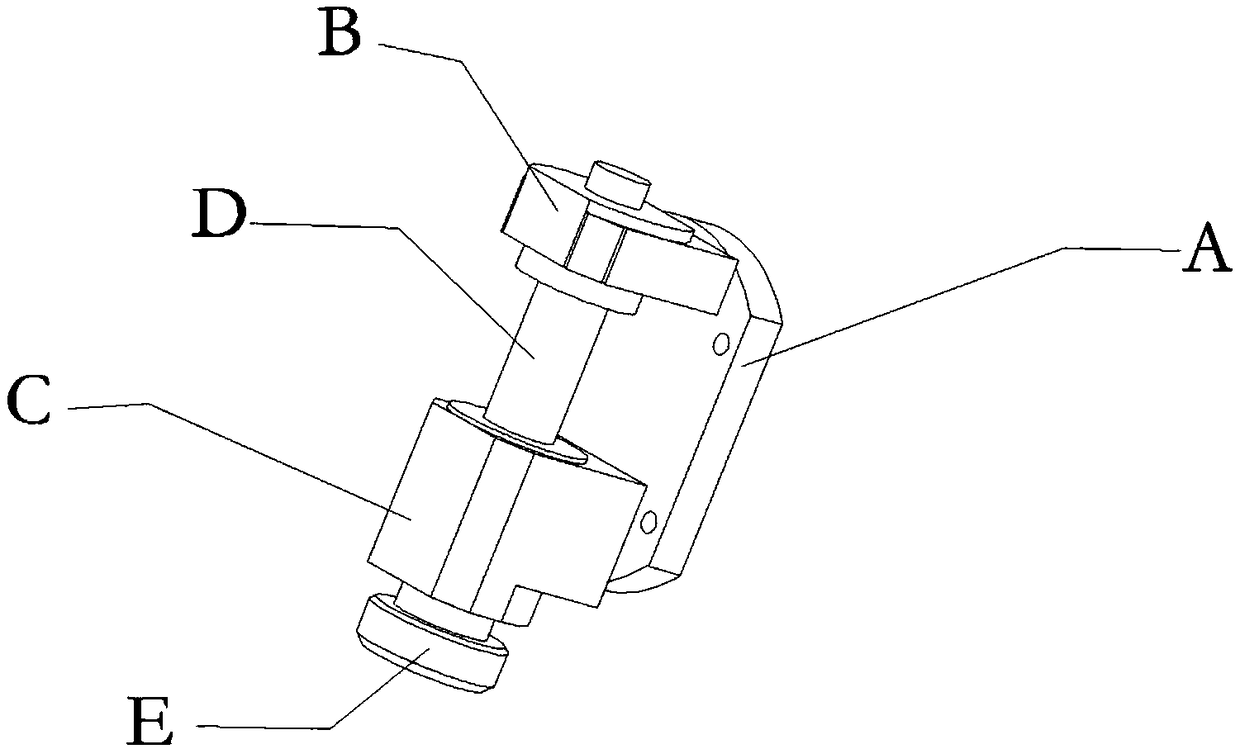

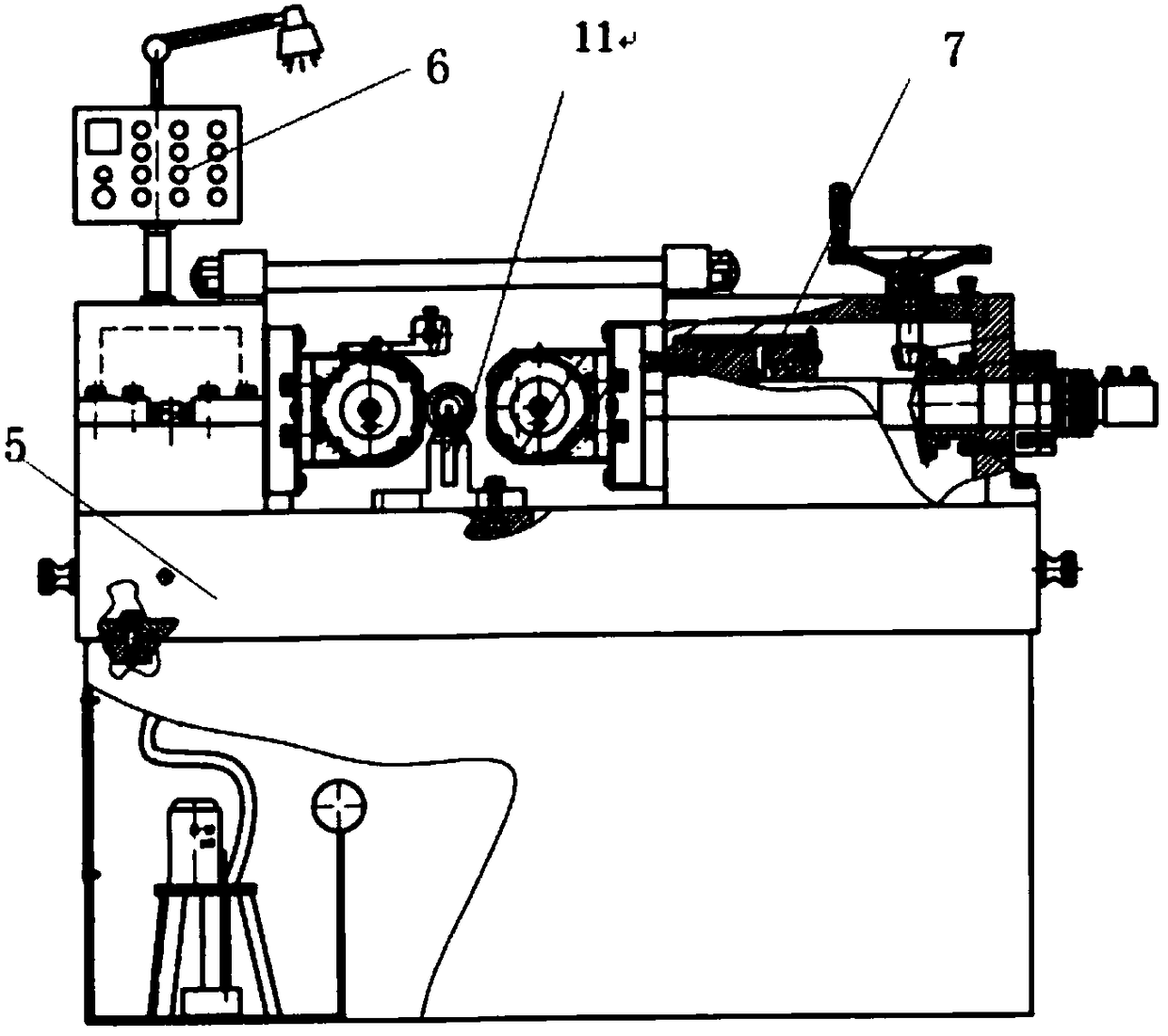

[0017] Such as Figures 1 to 4 As shown, the labels in the figure are: 1. Fixed main shaft seat; 2. Reciprocating main shaft seat; 3. Fixed thread rolling wheel; 4. Movable thread rolling wheel; Giving mechanism; 8. Transmission system; 9. Power distribution box; 10. Hydraulic system; 11. Reinforcement support; A. Main shaft base plate; B. Main shaft front support block; C. Main shaft rear support block; D. Main shaft; E. coupling.

[0018] The thread forming unit of the present invention includes a fixed spindle base 1 and a reciprocating spindle base 2; a fixed thread rolling wheel 3 is installed on the fixed spindle base 1, and a movable thread rolling wheel 4 is installed on the reciprocating spindle base 2 Wherein, the reciprocating main shaft seat 2 moves to the position of the fixed main shaft seat 1, so that the movab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com