Preparation method of catalyst for removing ammonia nitrogen in landfill leachate by electrolyzing and electrolyzing device thereof.

A technology of landfill leachate and electrolysis device, which is applied in the field of catalyst preparation and electrolysis device for electrolyzing landfill leachate to remove ammonia nitrogen, which can solve the problems of poor ammonia nitrogen removal effect, improve safety and stability, accelerate oxidation efficiency, and high removal rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of a catalyst for removing ammonia nitrogen from electrolytic landfill leachate, including the following steps:

[0029] Step 1: Grind the activated carbon powder through a 100-mesh screen, boil the activated carbon powder under the sieve in deionized water for 30 minutes and then cool, and repeat the sieving, boiling and cooling operations 3 times.

[0030] Step 2: Dry the activated carbon powder obtained in Step 1 at a temperature of 105-115°C until the activated carbon powder has a constant weight.

[0031] Step 3: Place the activated carbon powder obtained by drying in step 2 in the ferric chloride immersion solution for continuous stirring, soak until the adsorption is saturated, discard the supernatant, and wash the activated carbon with deionized water for 3 times at 105-115°C Dry for 24 hours under conditions to obtain metal-loaded activated carbon. Specifically, the volume ratio of the activated carbon powder to the ferric chloride impregnation so...

Embodiment 2

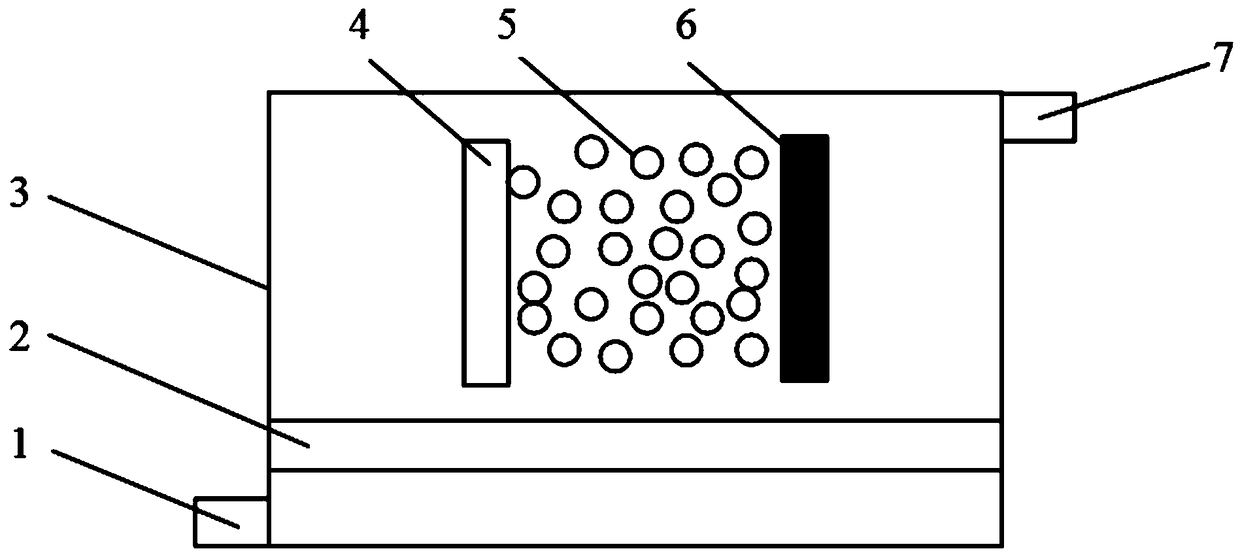

[0035] See attached figure 1 , An electrolysis device for electrolyzing a catalyst for removing ammonia and nitrogen from landfill leachate, comprising a reaction housing 3, a cathode plate 6 and an anode plate 4 in the reaction housing 3, and the catalyst for removing ammonia and nitrogen from the electrolytic landfill leachate described in Example 1. Preparation method prepared catalyst 5. The reaction shell 3 is made of insulating and pressure-resistant composite material. The area ratio of the cathode plate 6 and the anode plate 4 is 1:1, and the spacing is 2 cm. The reaction shell 3 is connected with a water inlet pipe 1 and a water outlet pipe 7, the water inlet pipe 1 communicates with the lower part on one side of the reaction shell 3, and the water outlet pipe 7 communicates with the upper part on the other side of the reaction shell 3 . An aeration pipe 2 is provided in the reaction shell 3. The aeration pipe 2 is arranged in the lower part of the reaction shell 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com