Non-fried lotus leaf noodles

A lotus leaf surface, non-fried technology, applied in food science, food preservation, food ingredients as taste improvers, etc. Safe and reliable source of ingredients, balanced nutrient intake, and the effect of enriching nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

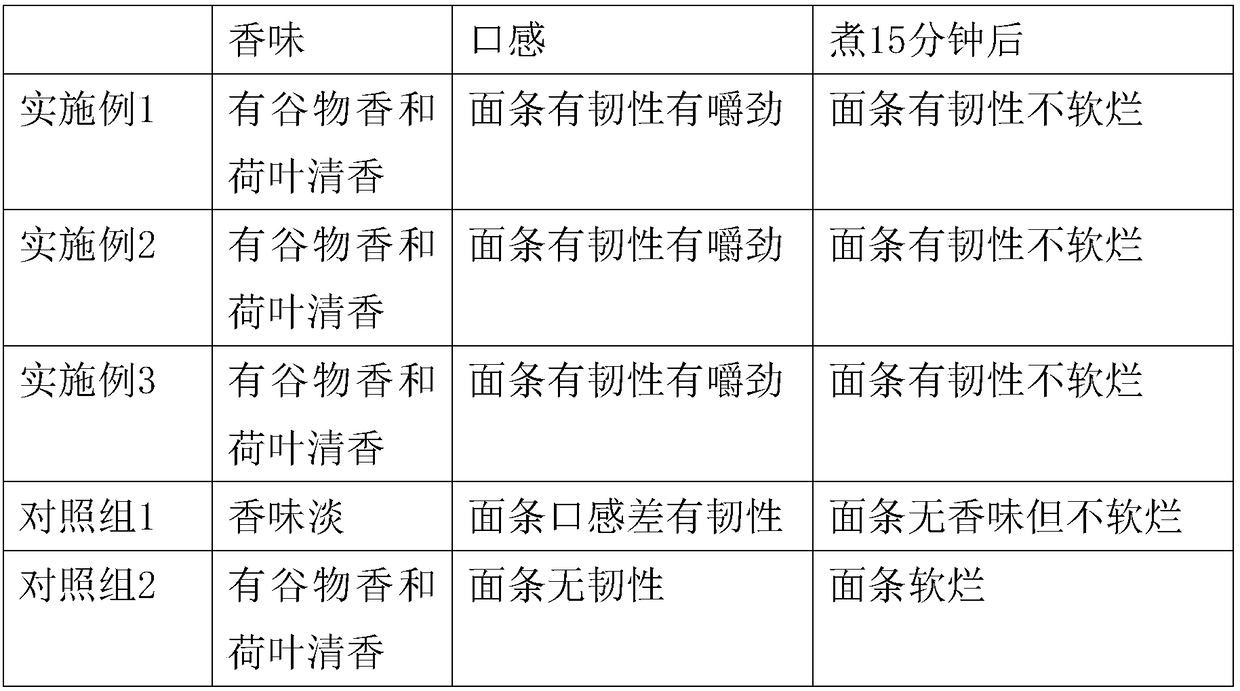

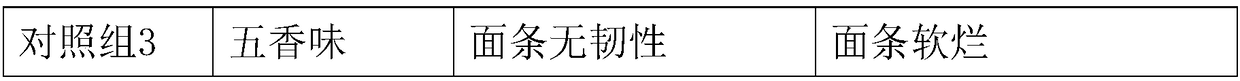

Examples

Embodiment 1

[0033] A non-fried lotus leaf noodle is characterized in that it consists of the following raw materials in parts by weight: 100 parts of wheat flour, 10 parts of eggs, 5 parts of edible salt, 5 parts of lotus leaves, 3 parts of lotus flowers, 3 parts of lotus seeds, brown rice 5 parts, 5 parts oats, 5 parts corn kernels, 2 parts antioxidant, 4 parts coconut oil.

[0034] Further, the antioxidant is prepared by the following method: soak the rice in water for 2 hours, dry it in the air, put it in a freezer at -20 degrees for 30 minutes, grind the frozen rice, grind the Add water and compound enzyme to the final rice flour, and carry out heat preservation and enzymolysis at a temperature of 35 ° C, then heat to reflux state, heat preservation and stirring for 10 minutes, centrifuge, take the upper layer of enzymolysis solution, and send the enzymolysis solution into a freeze dryer, The solid obtained by drying is made into micropowder through a superfine pulverizer to obtain an...

Embodiment 2

[0052] A non-fried lotus leaf noodle is characterized in that it consists of the following raw materials in parts by weight: 130 parts of wheat flour, 13 parts of eggs, 7 parts of edible salt, 8 parts of lotus leaves, 5 parts of lotus flowers, 5 parts of lotus seeds, brown rice 8 servings, 8 servings of oats, 8 servings of corn kernels, 4 servings of antioxidants, and 6 servings of coconut oil.

[0053] Further, the antioxidant is prepared by the following method: soak the rice in water for 2 hours, dry it in the air, put it in a freezer at -20 degrees for 30 minutes, grind the frozen rice, grind the Add water and compound enzyme to the final rice flour, and carry out heat preservation and enzymolysis at a temperature of 40°C, then heat to reflux state, heat preservation and stirring for 15 minutes, centrifuge, take the upper layer of enzymolysis solution, and send the enzymolysis solution into a freeze dryer, The solid obtained by drying is made into micropowder through a sup...

Embodiment 3

[0071] A non-fried lotus leaf noodle, characterized in that it consists of the following raw materials in parts by weight: 150 parts of wheat flour, 15 parts of eggs, 10 parts of edible salt, 10 parts of lotus leaves, 6 parts of lotus flowers, 6 parts of lotus seeds, brown rice 10 parts, 10 parts oats, 10 parts corn kernels, 5 parts antioxidants, 8 parts coconut oil.

[0072] Further, the antioxidant is prepared by the following method: soak the rice in water for 2 hours, dry it in the air, put it in a freezer at -20 degrees for 30 minutes, grind the frozen rice, grind the Add water and compound enzyme to the final rice flour, and carry out heat preservation and enzymolysis at a temperature of 45 ° C, then heat to reflux state, heat preservation and stirring for 15 minutes, centrifuge, take the upper layer of enzymolysis solution, and send the enzymolysis solution into a freeze dryer, The solid obtained by drying is made into micropowder through a superfine pulverizer to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com