Tea processing equipment based on solar power generation and heating

A processing equipment and solar energy technology, applied in photovoltaic power generation, photosensitive equipment, circuits, etc., can solve problems such as unsatisfactory energy demand, severe weather influence, and limited heat source temperature, so as to improve photoelectric conversion efficiency and reduce annihilation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

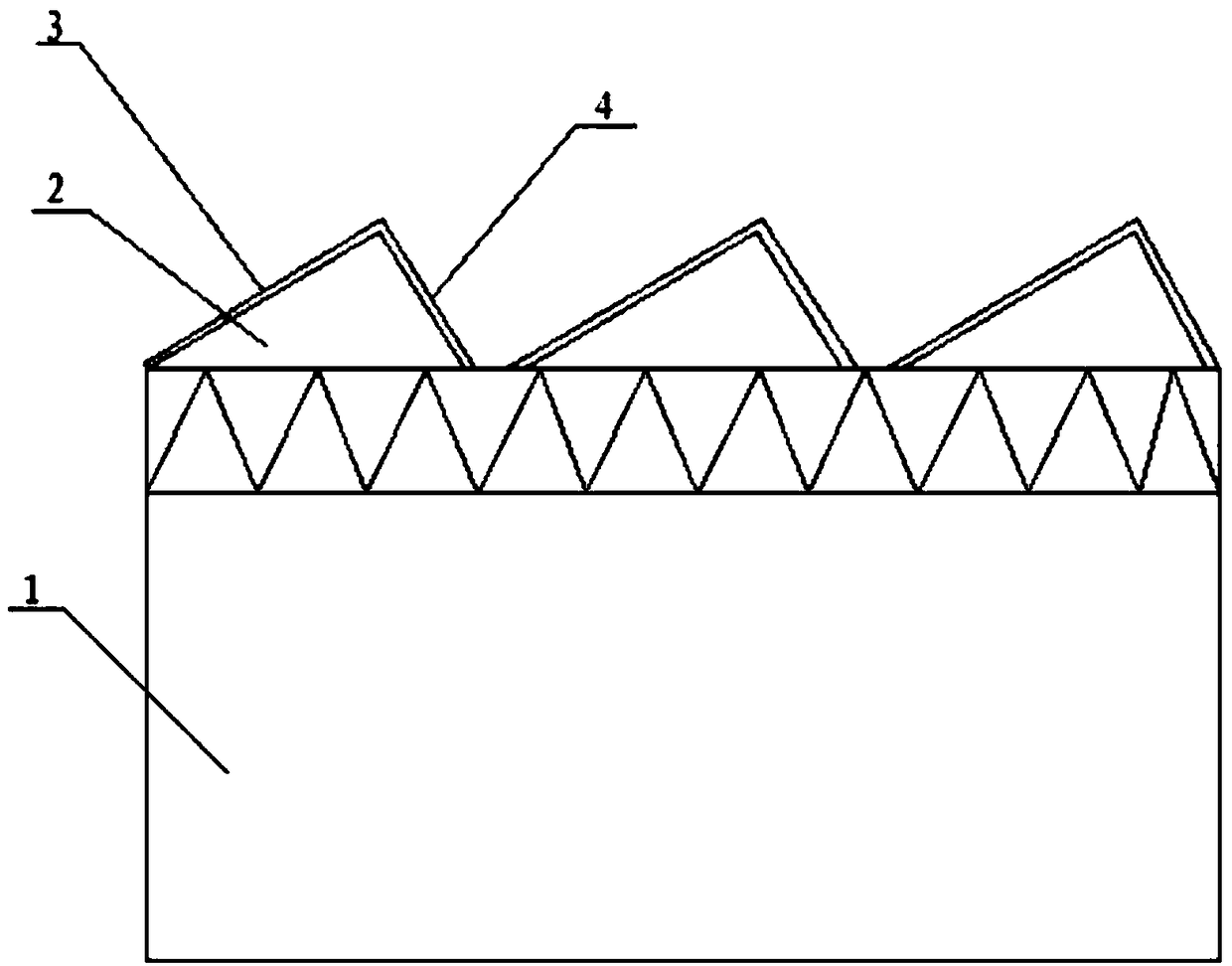

[0037] In this embodiment, the dye-sensitized solar cell includes a photoanode, a counter electrode, a dye, and an electrolyte, wherein the photoanode has a dye adsorbed on its surface, and the photoanode and the counter electrode are arranged opposite to each other with an electrolyte in between, forming a sandwich structure.

[0038] The photoanode includes an FTO substrate, a light-transmitting layer is arranged on the surface of the FTO substrate, and a scattering layer is arranged on the surface of the light-transmitting layer, and the light-transmitting layer and the scattering layer are formed by screen printing the light-transmitting layer slurry and the scattering layer slurry respectively , the thickness of the transparent layer is 5 μm, and the thickness of the scattering layer is 15 μm.

[0039] The light-transmitting layer includes TiO 2 Hollow sphere, MnO 2 Nanoparticles, Graphene and TiO 2 Nanoparticles, the mass ratio of the above-mentioned substances is 4:1:...

Embodiment 2

[0062] In this embodiment, the dye-sensitized solar cell includes a photoanode, a counter electrode, a dye, and an electrolyte, wherein the photoanode has a dye adsorbed on its surface, and the photoanode and the counter electrode are arranged opposite to each other with an electrolyte in between, forming a sandwich structure.

[0063] The photoanode includes an FTO substrate, a light-transmitting layer is arranged on the surface of the FTO substrate, and a scattering layer is arranged on the surface of the light-transmitting layer, and the light-transmitting layer and the scattering layer are formed by screen printing the light-transmitting layer slurry and the scattering layer slurry respectively , the thickness of the transparent layer is 10 μm, and the thickness of the scattering layer is 10 μm.

[0064] The light-transmitting layer includes TiO 2 Hollow sphere, MnO 2 Nanoparticles, Graphene and TiO 2 Nanoparticles, the mass ratio of the above-mentioned substances is 4:1...

Embodiment 3

[0086] In this embodiment, the dye-sensitized solar cell includes a photoanode, a counter electrode, a dye, and an electrolyte, wherein the photoanode has a dye adsorbed on its surface, and the photoanode and the counter electrode are arranged opposite to each other with an electrolyte in between, forming a sandwich structure.

[0087] The photoanode includes an FTO substrate, a light-transmitting layer is arranged on the surface of the FTO substrate, and a scattering layer is arranged on the surface of the light-transmitting layer, and the light-transmitting layer and the scattering layer are formed by screen printing the light-transmitting layer slurry and the scattering layer slurry respectively , the thickness of the transparent layer is 10 μm, and the thickness of the scattering layer is 10 μm.

[0088] The light-transmitting layer includes TiO 2 Hollow sphere, MnO 2 Nanoparticles, Graphene and TiO 2 Nanoparticles, the mass ratio of the above-mentioned substances is 4:1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com