Full-automatic poultry egg cleaning equipment

A kind of cleaning equipment and fully automatic technology, which is applied in poultry farming, application, animal husbandry, etc., can solve the problems of low cleaning efficiency, low efficiency, and slow development, and achieve the effects of reasonable design, improved cleaning efficiency, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

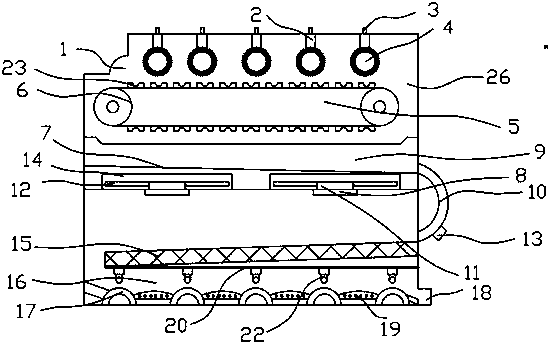

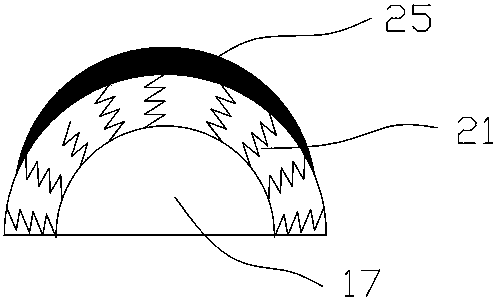

[0021] Such as Figure 1~4 Shown, a kind of full-automatic poultry and egg cleaning equipment comprises cleaning area 26, cleaning area 9, drying area 16, and the upper left side of cleaning area 26 is provided with feed inlet 1, and cleaning area 26 below is provided with cleaning Area 9, a drying area 16 is provided below the cleaning area 9, and a U-shaped pipe 10 is provided between the cleaning area 9 and the drying area 16. The U-shaped pipe 10 is located outside the right side of the cabinet, and the middle part of the U-shaped pipe 10 is provided Nozzle 13. The device is divided into 3 areas, multi-step combined cleaning, good cleaning effect, low cost, high efficiency, simple operation, no damage to poultry eggshells during the cleaning process, the setting of the U-shaped tube can make the cleaning area clean The poultry eggs pass smoothly into the lower layer, and on the other hand, the cleaned sewage can flow out from the water outlet on the side wall of the U-sha...

Embodiment 2

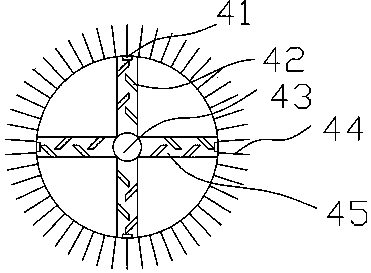

[0030] Such as Figure 1~4 As shown, when a kind of full-automatic poultry egg cleaning equipment of the present invention is actually used: put the poultry eggs that need to be cleaned one by one into the egg holder 23 in the feed hopper 1, the conveyor belt 5 transmits the poultry eggs forward, and the cleaning wheel 4 rotate, carry out preliminary cleaning to poultry egg, during cleaning, disinfectant can flow out from liquid storage tank 43, flow on poultry egg shell, poultry egg is disinfected and cleaned, and after cleaning area 26 is cleaned, poultry egg Will fall into the cleaning area 9 by gravity from the far right side of the conveyor belt 5, the rotation of the mixing blade 12 in the cleaning area 9 will drive the water flow to be in a vortex, and the vortex-like water flow has strengthened the disinfectant on the surface of poultry eggs, cleaning the water The dirt is decomposed, and after the cleaning in the cleaning area 9 is completed, the water flows out from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com