High-efficiency and energy-saving lawn harvester

A high-efficiency, energy-saving, harvester technology, used in harvesters, cutters, agricultural machinery and implements, etc., can solve problems such as inconvenience for long-term work, lawn mower vibration affecting the work of operators, and portable operation of lawn mowers. Easy to operate, reasonable design, strengthen the effect of management and care

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

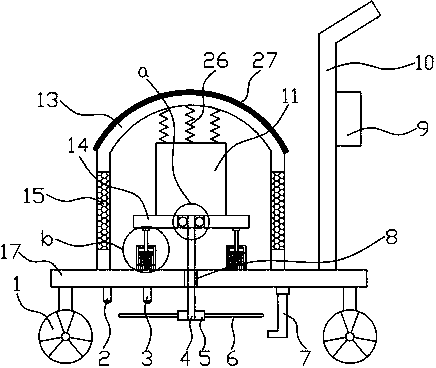

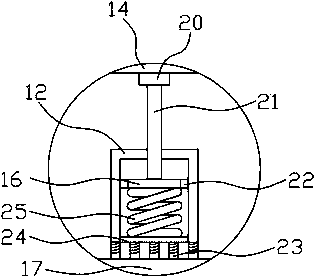

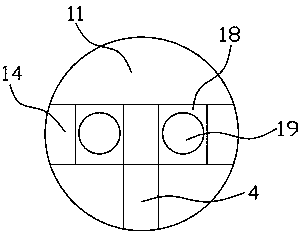

[0026] Such as Figure 1~4 As shown, a high-efficiency and energy-saving lawn harvester includes a motor 11, the motor 11 is connected to the upper surface of the horizontal plate 17 through a shock absorbing mechanism, and the rotating shaft 4 of the motor 11 extends to the horizontal plate through the rotating shaft through hole 8 on the surface of the horizontal plate 17 Below 17, the lower surface of the rotating shaft 4 is connected with a collar 5, the surface of the collar 5 is connected with a blade 6, the front and rear ends of the bottom surface of the horizontal plate 17 are connected with rollers 1, and the bottom of the horizontal plate 17 is connected with an infrared sensor I2 at a range far away from the blade 6. The bottom of the horizontal plate 17 is connected with an infrared sensor II 3 within the range of the blade 6 , and the two sides of the roller 1 are connected with extension bars 28 . The motor 11 is connected to the surface of the horizontal plate ...

Embodiment 2

[0034] Such as Figure 5~6 As shown, the present embodiment is a further optimization scheme based on Embodiment 1: the blade 6 is connected with a sponge block 6a at the bottom of one side of the blade 6 against the rotating shaft 4, and the ratio of the thickness h2 of the sponge block 6a to the thickness h1 of the blade 6 is 1: 2~3, the blade 6 cuts the grass, and a sponge block 6a is connected to the bottom of the rotating shaft 4 of the blade 6 on the opposite side, so that after the blade 6 cuts the grass, the sponge block 6a can be cut with the grass at a faster speed. The resulting friction on the surface of the wound makes the secretion of the grass itself quickly form a breathable protective film at the wound, so that the wound is closed and blocked, effectively preventing the breeding of mosquitoes due to the grass wound and the secretion of its wound juice after the lawn is trimmed , the situation of bacteria, can also reduce the loss of nutrients in the trimmed gr...

Embodiment 3

[0037] The working principle of the present invention is: place the harvester of the present invention where the lawn needs to be pruned, operate the controller 9 to make the motor 11 work, the operator only needs to push the harvester to move through the pull rod 10 when mowing the lawn, and the motor 11 drives the blade 6 generates rotation to realize the cutting of the grass. The shock absorbing mechanism at the bottom of the motor 11 minimizes the vibration during the working process of the motor 11. The infrared sensor I2 and infrared sensor II3 detect the position of the bottom surface and the blade 6, and feed back the value to the controller After 9, the controller 9 controls the electric telescopic rod 23 to adjust up and down so as to achieve the best cutting effect. During the harvesting process, the solar panel 27 continuously converts solar energy into electrical energy and charges the battery inside the controller 9, thereby providing the harvester as a whole. Pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com