2.0micron-band low-threshold single-frequency fiber laser of employing neodymium-holmium-ytterbium tridoped tellurate fiber

A fiber laser and tellurite technology, which is applied in lasers, laser components, phonon exciters, etc., can solve the problems of low single-frequency laser output power, high threshold power, and low threshold, so as to improve luminous intensity and reduce Threshold power, effect of increasing laser output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

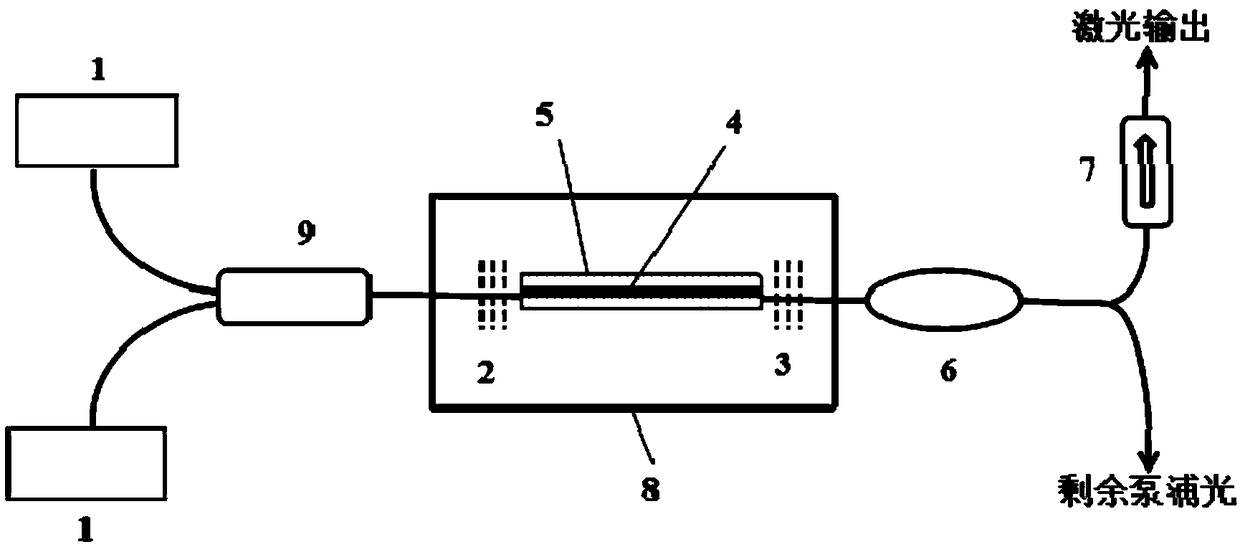

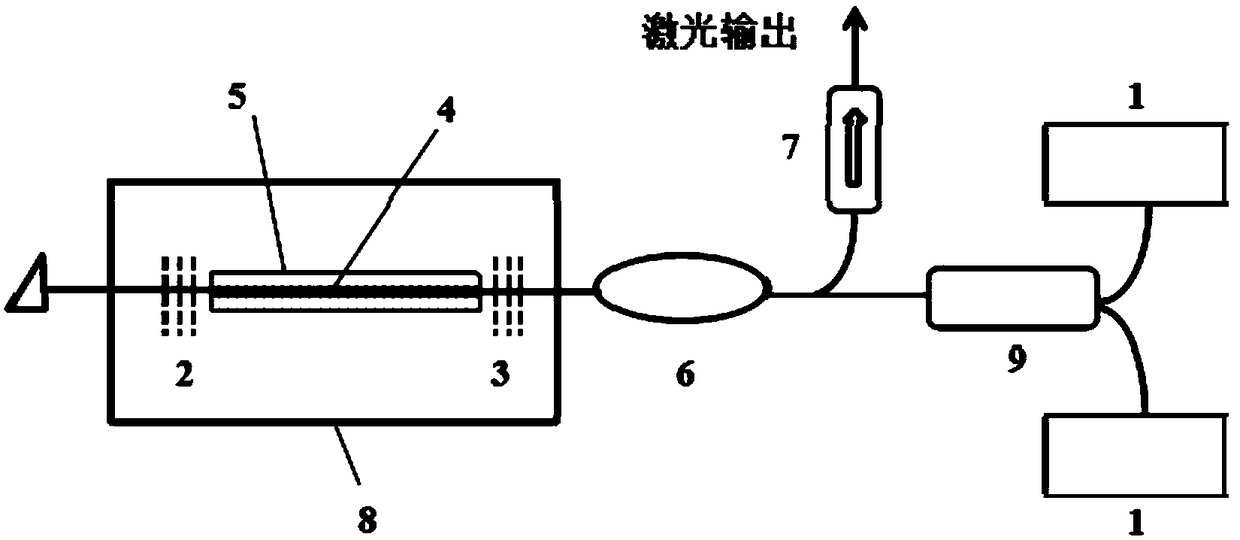

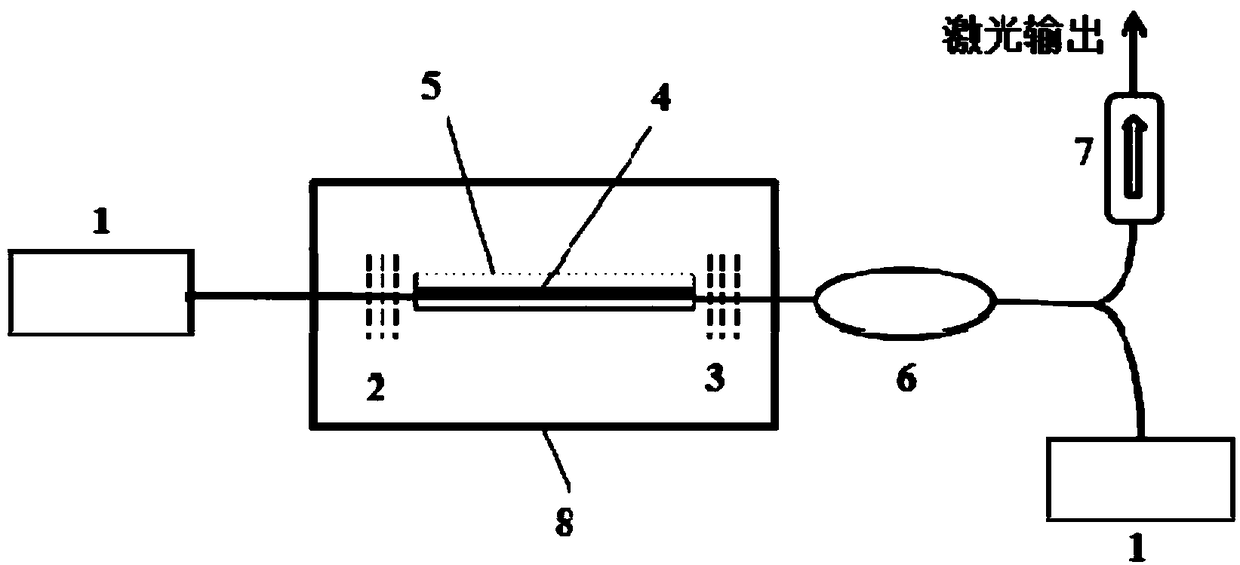

[0028] Figure 1-Figure 3 It is a schematic structural diagram of the principle structure of the 2.0 μm band low-threshold single-frequency fiber laser of the neodymium holmium ytterbium tri-doped tellurate fiber of the embodiment of the present invention, and the 2.0 μm band low-threshold single-frequency fiber laser of the neodymium holmium ytterbium tri-doped tellurate fiber consists of Composed of single or double 808nm semiconductor laser pumping source, broadband fiber Bragg grating, narrowband fiber Bragg grating, gain fiber, capillary packaging material, wavelength division multiplexer, optical isolator, automatic temperature control system, and fiber combiner; each part The connection relationship is: one end of the wavelength division multiplexer is connected to one end of the narrowband fiber Bragg grating, the other end of the narrowband fiber Bragg grating is connected to one end of the broadband fiber Bragg grating through the gain fiber, and the other end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com