Prediction method for creep inoculation period considering residual stress under plastic condition

A technology of residual stress and prediction method, applied in the direction of measuring device, strength properties, and ductility of testing materials, which can solve the problems of unresearched influence and service life of components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

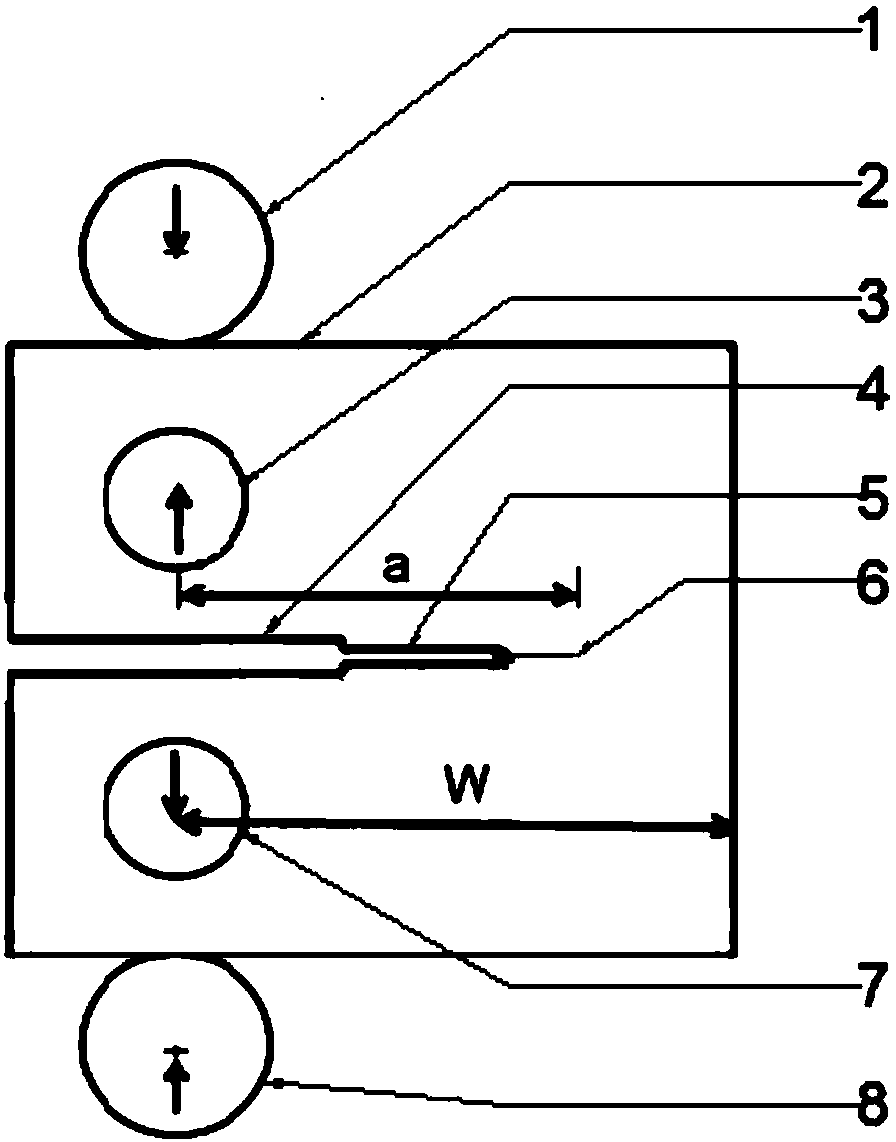

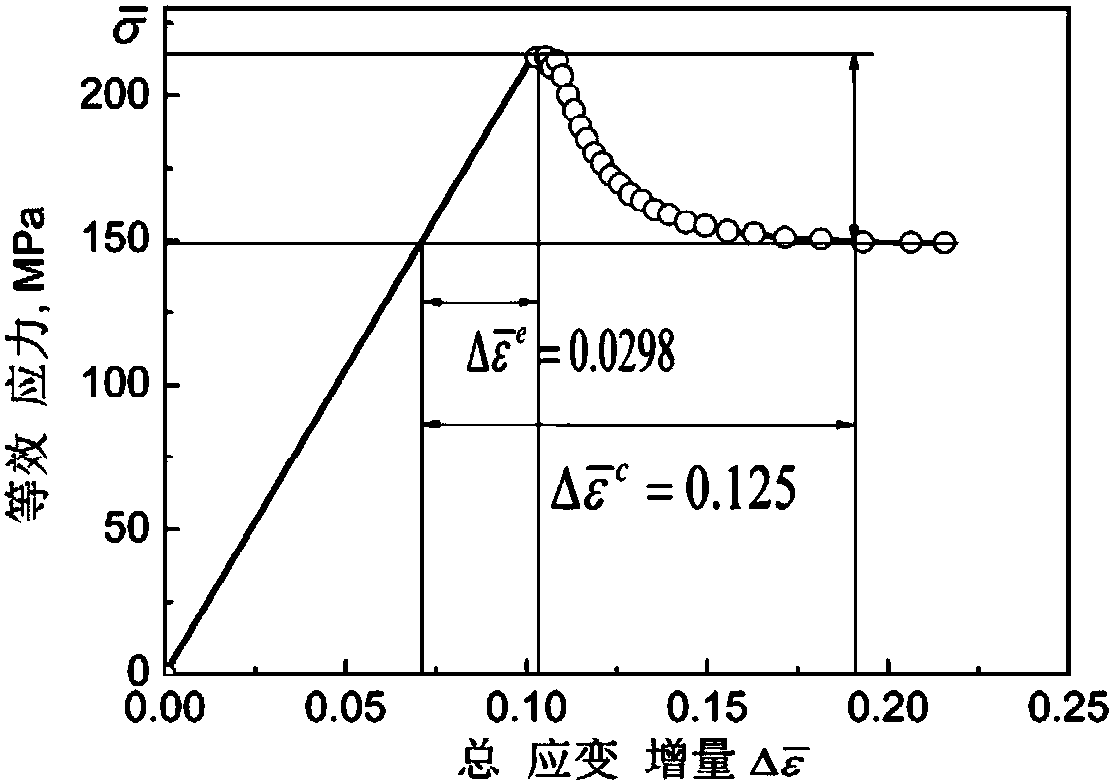

[0062] In this embodiment, P92 high-temperature heat-resistant steel is selected, a CT sample with B=20mm, W=40mm, a / W=0.5 is taken as the research object, and the preload is 12000N and the main load P=12000N as the research load. Its main material properties are shown in the table below:

[0063]

[0064] Among them: E-16 is 10 to the power of -16.

[0065] The creep incubation period prediction method containing residual stress under the plastic condition of the present invention comprises the following steps:

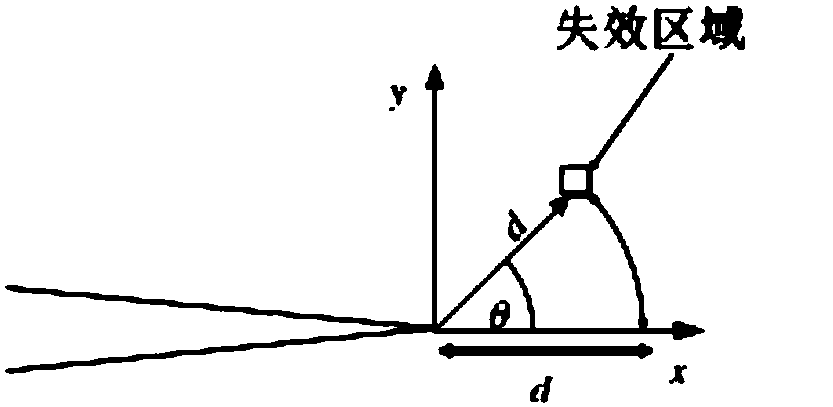

[0066] S1: Create as figure 1 The model shown: the model includes a CT sample body 2, a groove 4 is provided at the front end of the middle part of the CT sample body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com