Conveying device and developing machine

A transmission device and developing machine technology, applied in photography, optomechanical equipment, optics, etc., can solve problems such as poor developing effect, affecting developing effect, insufficient removal of unexposed photoresist, etc., to improve uniformity and promote uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

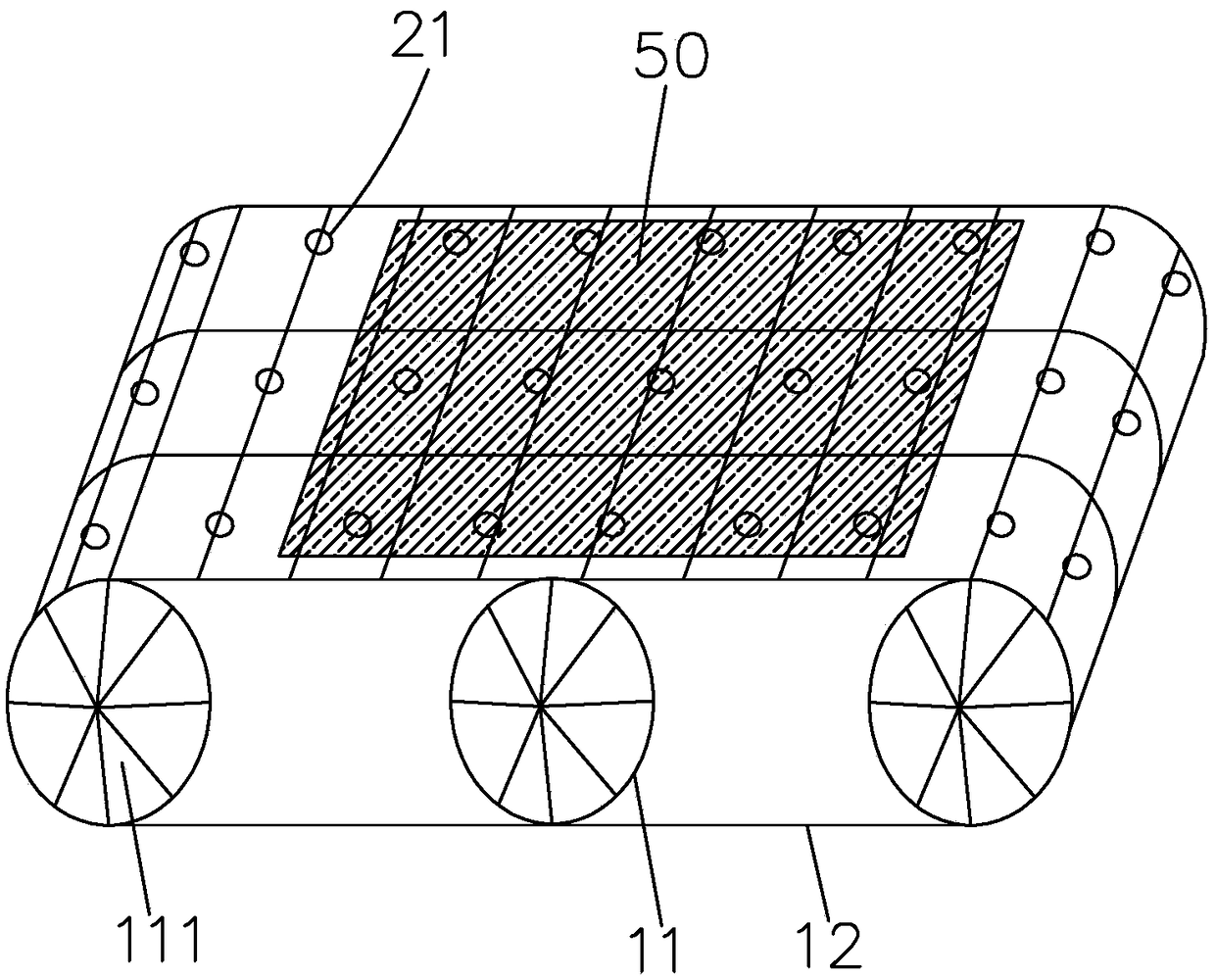

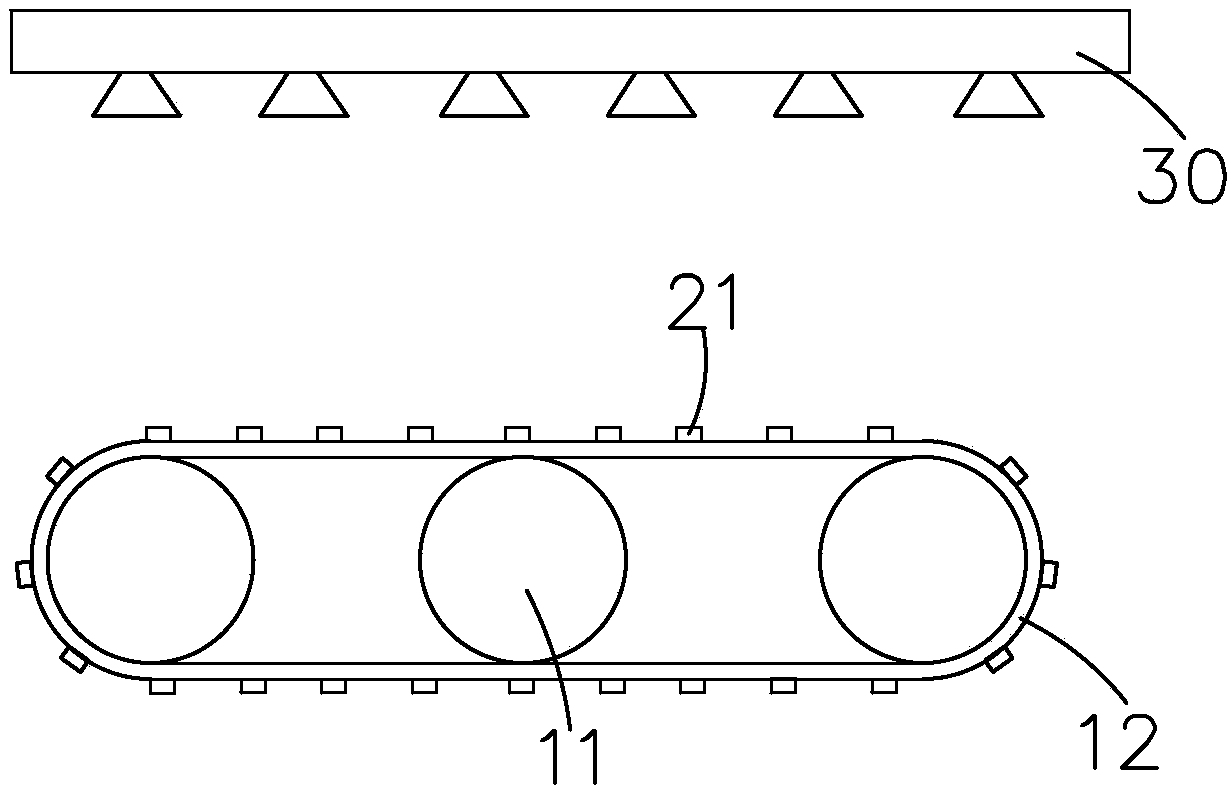

[0026] see figure 1 , the present invention firstly provides a conveying device for transferring a substrate 50 in a developing machine. A plurality of ultrasonic support protrusions 21 on the

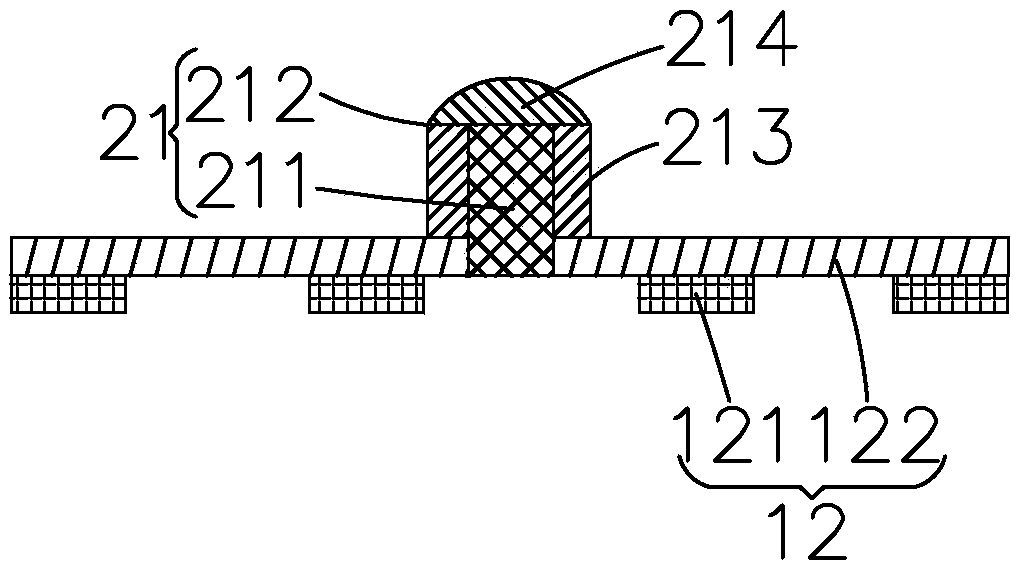

[0027] Among them, such as figure 2 As shown, each ultrasonic support protrusion 21 includes an ultrasonic vibrator 211 and a support cover 212 covering the ultrasonic vibrator 211 on the conveyor belt 12, and the ultrasonic support protrusion 21 is used as a defoaming component for eliminating bubbles in the developer;

[0028] During the process of transporting the substrate 50, the substrate 50 is supported by the ultrasonic support protrusion 21 and is in contact with the ultrasonic support protrusion 21. The ultrasonic support protrusion 21 emi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com