Graded direct-reading method and device for surface hydrophobicity of composite insulating material

A technology of composite insulation and insulating materials, which is applied in the direction of testing composite materials, material analysis by optical means, measuring devices, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

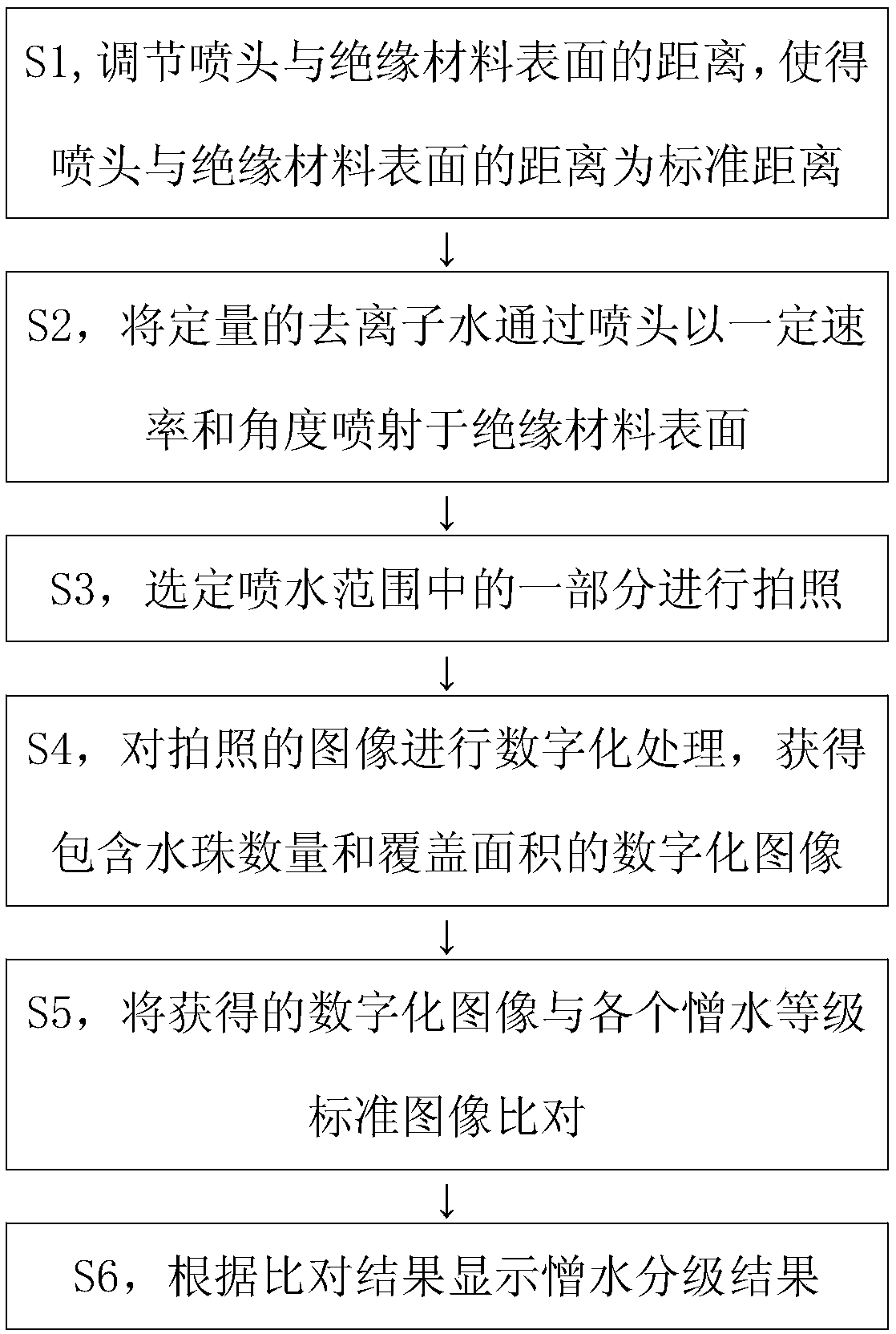

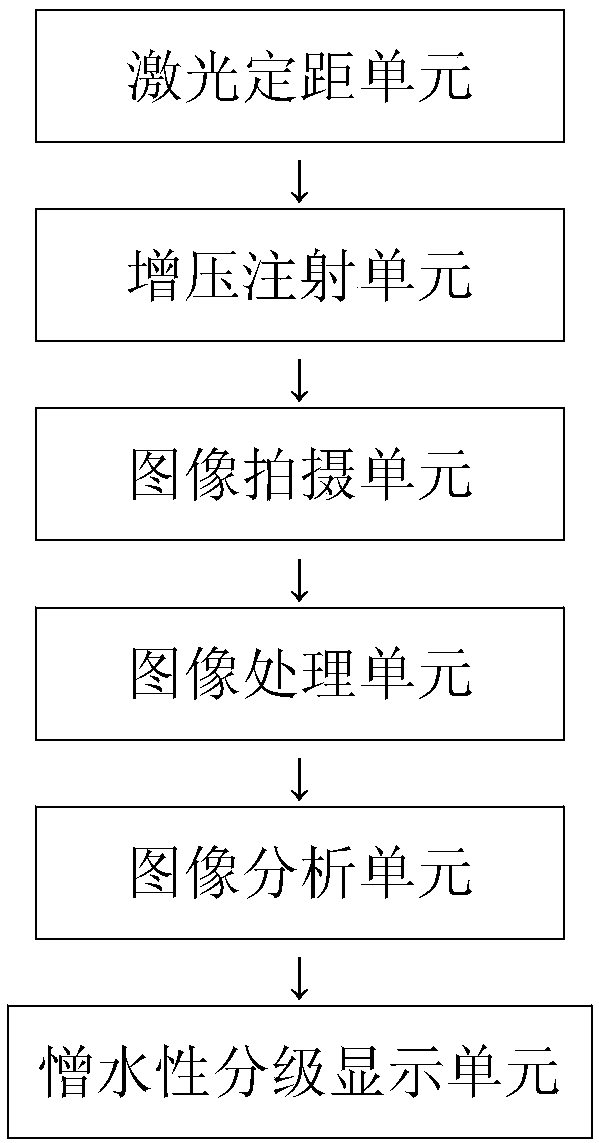

[0042] like figure 1 As shown, embodiment 1 provides a kind of composite insulation material surface hydrophobicity graded direct reading method and device, described method comprises the following steps:

[0043] S1, adjust the distance between the nozzle and the surface of the insulating material, so that the distance between the nozzle and the surface of the insulating material is a standard distance. In this process, when adjusting the distance between the nozzle and the surface of the insulating material, the principle of laser ranging can be used to automatically adjust the distance between the nozzle and the surface of the insulating material through the control chip and the motor. The final standard distance is 25cm.

[0044] S2, spray a certain amount of deionized water on the surface of the insulating material through the nozzle at a certain speed and angle. Among them, the amount of water sprayed by the nozzle is 5ml, the spray rate is 0.5ml / s, and the spray angle ...

Embodiment 2

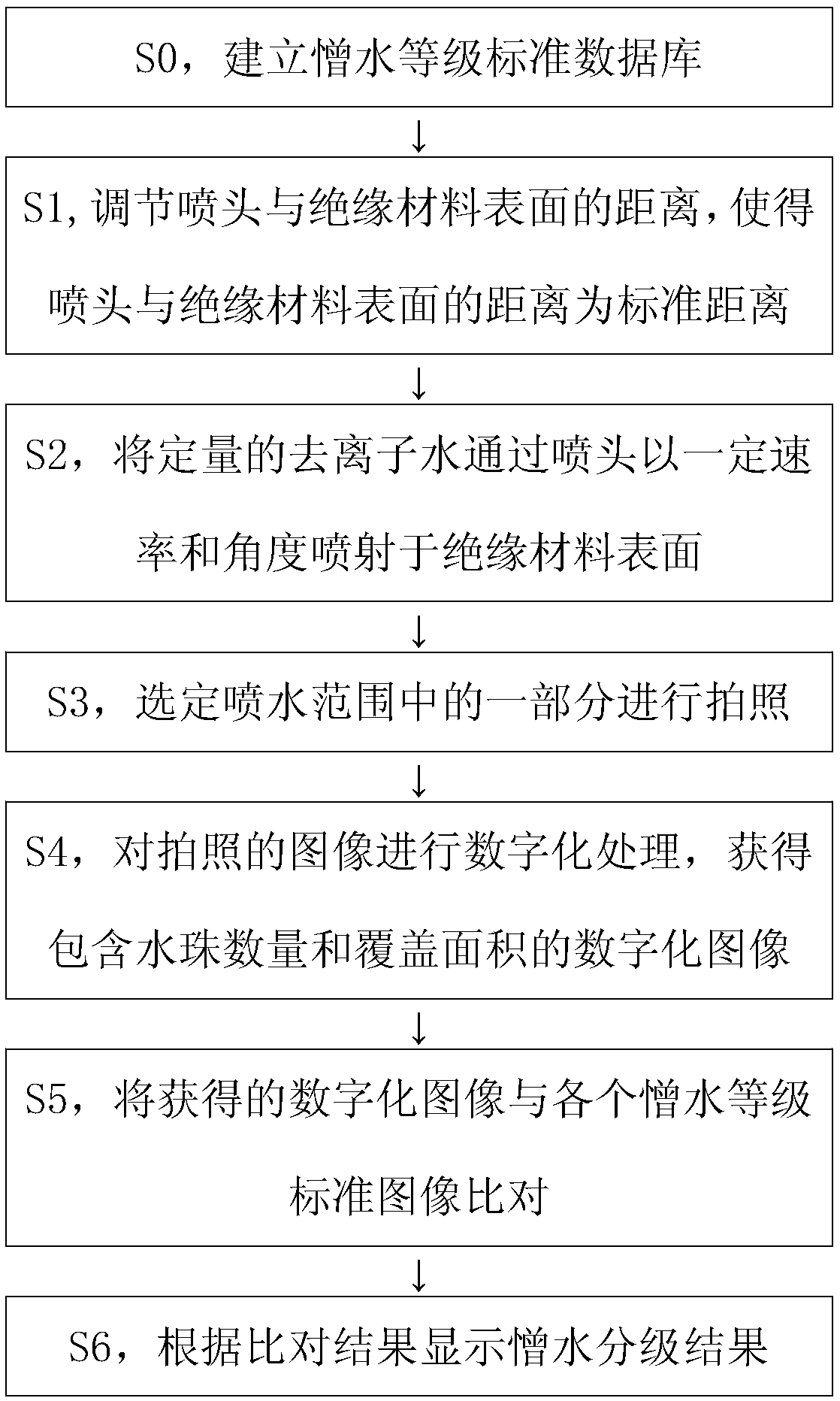

[0057] like image 3 As shown, embodiment 2 provides a kind of composite insulation material surface hydrophobicity classification direct reading method and device, described method comprises the following steps:

[0058] S0, establishing a standard database of hydrophobic grades, wherein the standard image corresponding to each hydrophobic grade is stored in the standard database of hydrophobic grades.

[0059] The specific implementation process of step S0 is as follows: obtain the composite insulating material whose hydrophobicity level has been determined; spray water on the surface of the composite insulating material and take a picture; digitize the number of water drops and the coverage area in the photographed image to obtain a standard image ; Repeat the above steps until the standard image corresponding to each hydrophobicity grade is obtained.

[0060] S1, adjust the distance between the nozzle and the surface of the insulating material, so that the distance betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com