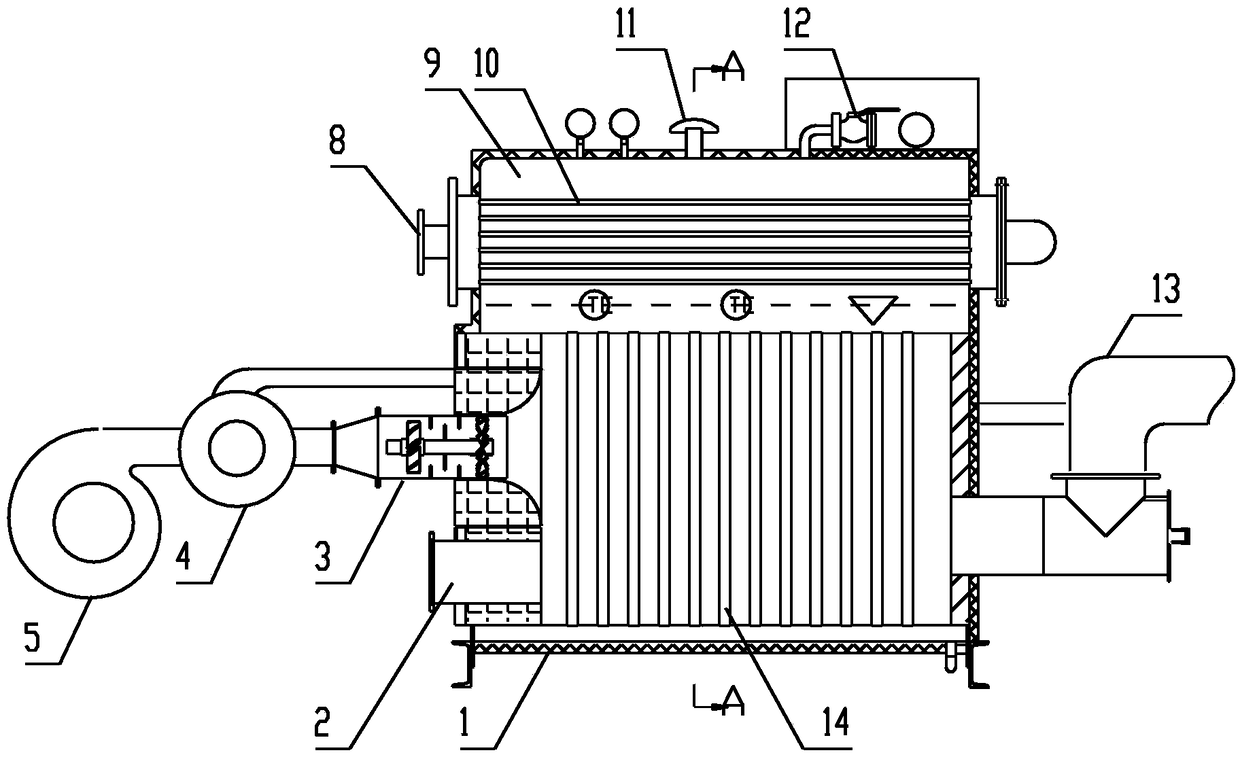

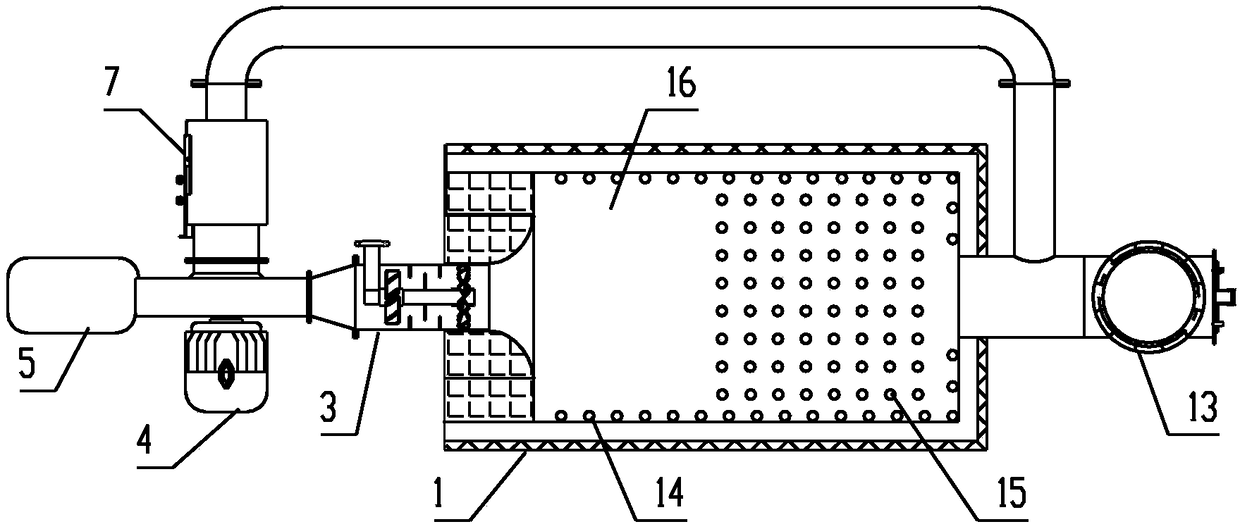

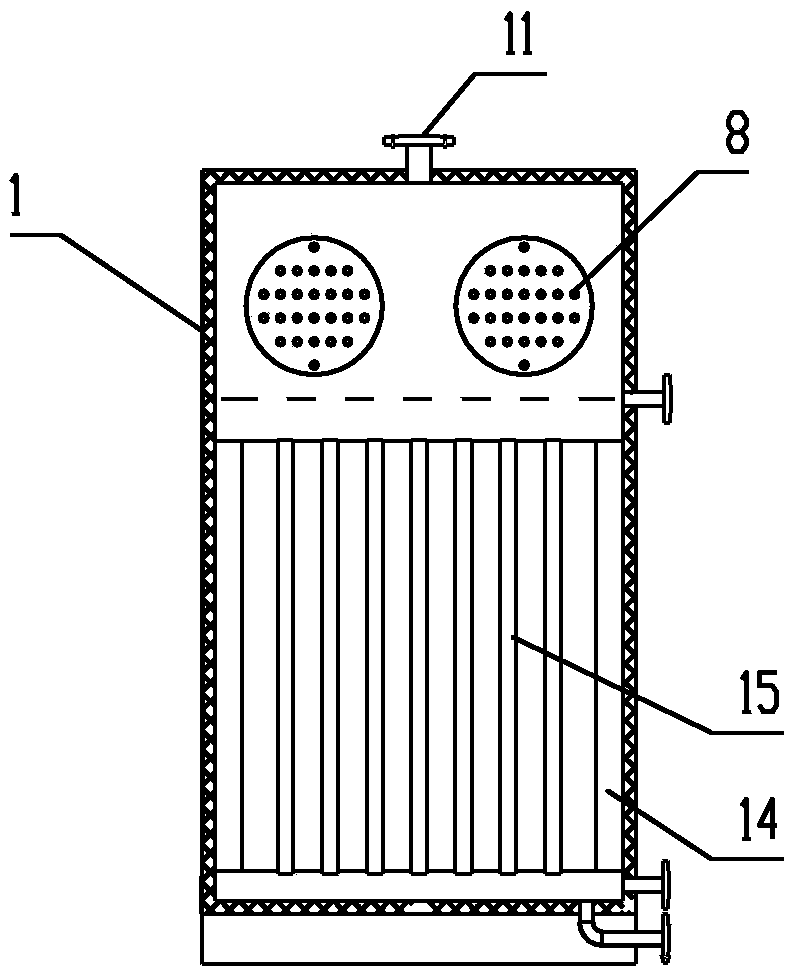

Dish-shaped flame low-nitrogen negative-pressure hot water unit and operation method thereof

A hot water unit, dish-shaped technology, applied in thermal storage heaters, fluid heaters, lighting and heating equipment, etc., can solve problems to be improved, operation explosion, etc., to save the cost and safety of personnel training and management The effect of improving and easy onboarding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0046] Embodiment 2: The dish flame low nitrogen negative pressure hot water unit is optimized on the basis of the structure of embodiment 1. A circulating water temperature sensor and a circulating water pressure sensor are provided in the circulating water circulation system; a combustion chamber is provided in the combustion chamber. chamber temperature sensor and combustion chamber pressure sensor; the gas valve, air blower, and flue gas induced draft fan are equipped with self-controlled frequency converters to control the flow; a nitrogen oxide concentration sensor is installed in the exhaust gas pipe; and a PLC controller and The circulating water temperature sensor and the circulating water pressure sensor, the combustion chamber temperature sensor and the combustion chamber pressure sensor, the gas valve and the air blower, the automatic control frequency converter of the flue gas induced draft fan, and the nitrogen oxide concentration sensor are connected for signal an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com