A rapid construction method for mechanical excavation of urban hard rock tunnels

A construction method and tunnel technology, applied in tunnels, earth-moving drilling, mining equipment, etc., can solve the problems of high safety risk, low work efficiency, low seismic level, etc., and achieve the effect of high degree of mechanization, improved work efficiency, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

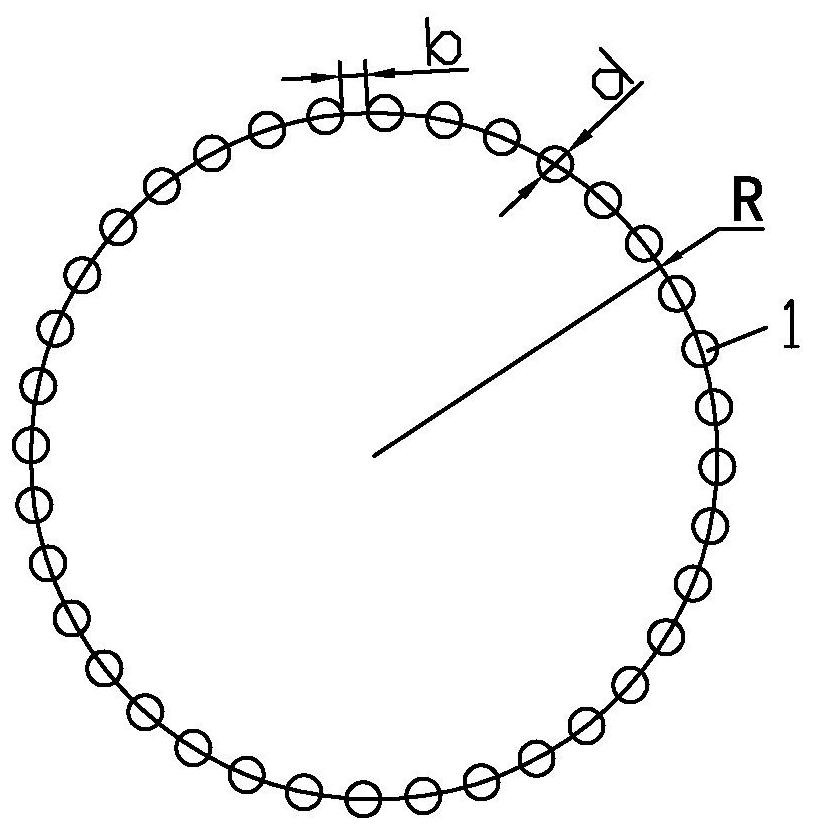

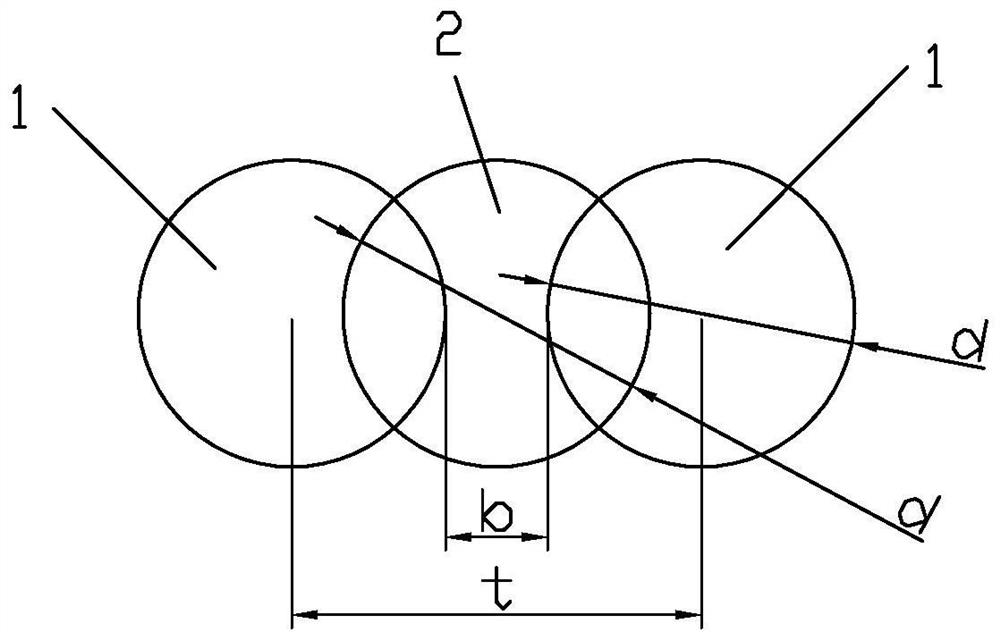

[0027] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , a kind of urban hard rock tunnel mechanical excavation fast construction method, comprises the following steps:

[0028] The first step, tunnel contour drilling and coring: according to the tunnel section shape required by the design, a multi-hole combined water mill drilling rig with multiple drill bits operating at the same time is used to drill and coring along the outer periphery of the tunnel excavation contour to form the tunnel excavation area Peripheral continuous air surface of section profile;

[0029] The second step, drilling and coring the tunnel face: continue to use the multi-hole combined water mill drilling rig with multiple drill bits working at the same time, drill and core the tunnel face in or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com