Decorative composite board with surface-coated fluorine-carbon paint

A technology of surface coating and fluorocarbon paint, applied in the direction of coating, floor, building components, etc., can solve the problems affecting the waterproof and decorative effect of thermal insulation surface layer, improve the utilization efficiency and resource reuse ability, meet the The effect of individual needs, improving production efficiency and craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

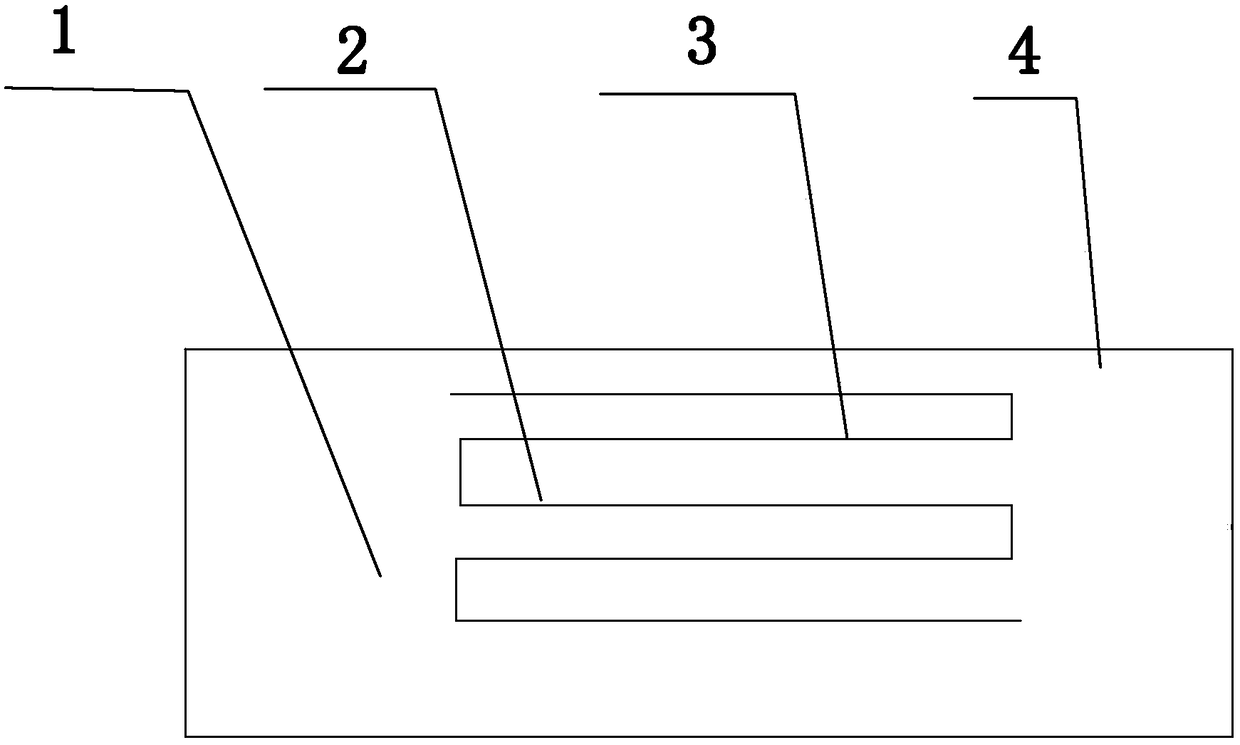

[0023] The decorative composite board is a multi-layer composite board, the surface layer is fluorocarbon paint 1, the middle layer is silicon-calcium board 2, the inner layer is an insulation layer 3, and a thin plate 4 is sandwiched in the middle of the insulation layer. The insulation layer 3 is made of polystyrene Resin is the raw material, and the thin plate is the reinforced aluminum plate, which is made of aluminum alloy panel with brushed surface.

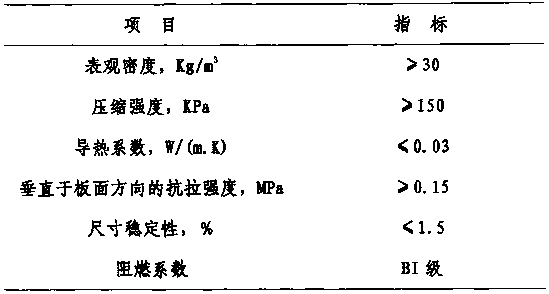

[0024] The insulation layer is made of polystyrene resin as a raw material, which is continuously extruded and foamed by a special process. Its interior is an independent closed air bubble structure. It is an environmentally friendly thermal insulation material with excellent properties such as light weight, corrosion resistance, long service life, and low thermal conductivity.

[0025]

[0026] A method for manufacturing interior and exterior wall decorative panels, including the following two major technological proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com