A method and apparatus for controlling stress variation in a material layer formed via pulsed DC physcial vapor deposition

A technology to control pulse and stress changes, which is applied in the coating process of metal materials, microstructure devices composed of deformable elements, coatings, etc., and can solve problems such as uneven stress distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

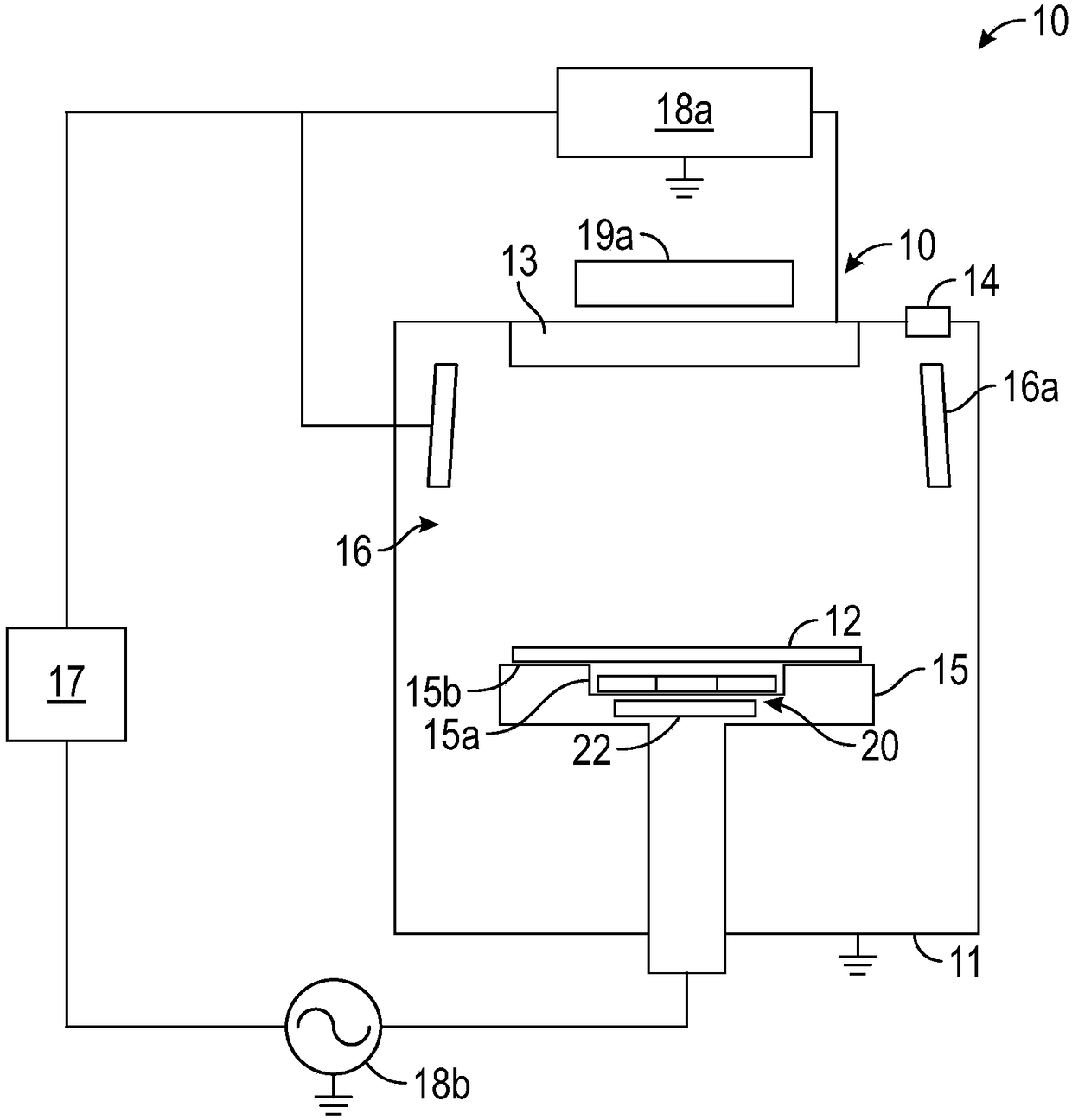

[0059] refer to image 3 , which shows a schematic diagram of an apparatus 10 for controlling stress variation in a material layer (not shown) formed on a substrate by physical vapor deposition according to an embodiment of the present invention. Apparatus 10 includes an electrically grounded processing chamber 11 within which a physical vapor deposition process takes place. The chamber 11 is arranged to house a substrate, such as a silicon wafer 12 , and source or target material 13 , which may include a metal planar layer, such as an aluminum disk, to form a sputtered layer on the wafer 12 . The chamber 11 also includes an inlet 14 for coupling to a gas source (not shown), such as, for example, the noble gases krypton, neon or argon, and a reactive gas such as nitrogen or oxygen to A nitride film or an oxide film is formed. Apparatus 10 also includes a platen 15 on which wafer 12 is located within chamber 11 . The platen 15 is placed within the chamber 11 so that the wafe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com