Degradable plastic film raincoat

A plastic film and raincoat technology, applied in the field of degradable plastic film raincoats, can solve the problems of white pollution, long degradation time, and general degradation performance of environmental protection raincoats, so as to improve wet compressive strength, rheological properties, and biodegradability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

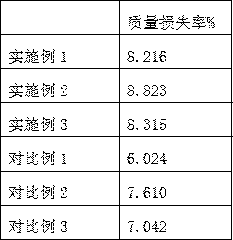

Examples

Embodiment 1

[0019] A degradable plastic film raincoat, made of the following components in parts by weight: polyvinyl chloride resin 88, silicon-doped starch 16, phenolic resin 10, dilauryl thiodipropionate 1, acetyl trioctyl citrate 0.1, lauryl glucoside 0.1, aluminum borate whisker 5, polycaprolactone 2, inorganic filler 15, plasticizer 1.0, dispersant 1.2.

[0020] Further, the average degree of polymerization of the polyvinyl chloride resin is 1100.

[0021] Further, the preparation method of the silicon-doped starch is:

[0022] (1) Soak the starch in a sodium citrate solution with a mass fraction of 0.1% in a water bath at 80°C for 30 minutes at a constant temperature, then filter, dry to constant weight, and then use 300W microwave treatment for 20-30s;

[0023] (2) According to the amount of 0.8mmol sodium trimethylsilyl acetate per gram of the above-mentioned treated starch, add the above-mentioned treated starch to a 1.2% sodium trimethylsilyl acetate solution, and then Stir i...

Embodiment 2

[0032] A degradable plastic film raincoat, made of the following components in parts by weight: polyvinyl chloride resin 95, silicon-doped starch 18, phenolic resin 15, dilauryl thiodipropionate 3, acetyl trioctyl citrate 0.3, lauryl glucoside 0.6, aluminum borate whisker 10, polycaprolactone 4, inorganic filler 18, plasticizer 1.2, dispersant 1.6.

[0033] Further, the average degree of polymerization of the polyvinyl chloride resin is 1100.

[0034] Further, the preparation method of the silicon-doped starch is:

[0035] (1) Soak the starch in a sodium citrate solution with a mass fraction of 0.1% in a water bath at 80°C for 30 minutes at a constant temperature, then filter, dry to constant weight, and then use 300W microwave treatment for 20-30s;

[0036] (2) According to the amount of 1.2mmol sodium trimethylsilyl acetate per gram of the above-mentioned treated starch, add the above-mentioned treated starch to a 1.2% sodium trimethylsilyl acetate solution, and then Stir ...

Embodiment 3

[0045] A degradable plastic film raincoat, made of the following components in parts by weight: polyvinyl chloride resin 92, silicon-doped starch 17, phenolic resin 12, dilauryl thiodipropionate 2, acetyl trioctyl citrate 0.2, dodecyl glucoside 0.3, aluminum borate whisker 8, polycaprolactone 3, inorganic filler 16, plasticizer 1.0-1.2, dispersant 1.4.

[0046] Further, the average degree of polymerization of the polyvinyl chloride resin is 1100.

[0047] Further, the preparation method of the silicon-doped starch is:

[0048] (1) Soak the starch in a sodium citrate solution with a mass fraction of 0.1% in a water bath at 80°C for 30 minutes at a constant temperature, then filter, dry to constant weight, and then use 300W microwave treatment for 20-30s;

[0049] (2) According to the amount of 0.9 mmol sodium trimethylsilylacetate per gram of the above-mentioned treated starch, add the above-mentioned treated starch into a 1.2% sodium trimethylsilylacetate solution, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com