A highly water-resistant waterborne polyurethane modified montmorillonite nanocomposite emulsion

A nano-composite and montmorillonite technology, applied in the field of organic-inorganic nano-composite emulsion, can solve the problems of limited wide application, decline, and insignificant improvement in water resistance of the system, and achieve improved mechanical properties, high strength, and good moisture absorption resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: the preparation of aqueous polyurethane emulsion and film

[0035] Add 24.08g of isophorone diisocyanate (IPDI) and four drops of dibutyltin dilaurate (DBTDL) catalyst into a 250mL four-necked flask equipped with a stirrer, a thermometer and a reflux condenser. Add 70.92g of polycarbonate diol (PCD2000) dropwise into the funnel, and the dropping rate is controlled within 1.5h. After the addition is completed, react at 50±5°C for 1-2h, and the temperature is controlled at 40-50°C; then raise the temperature to 60±5°C ℃, add 5g of dimethylolpropionic acid (DMPA), and react for 3-5h; measure the degree of reaction by toluene-di-n-butylamine back titration until the determined NCO group content reaches the theoretical value; obtain a polyurethane prepolymer.

[0036] Adding deionized water dropwise to the polyurethane prepolymer system for emulsification; forming a film and drying to obtain a water-based polyurethane film.

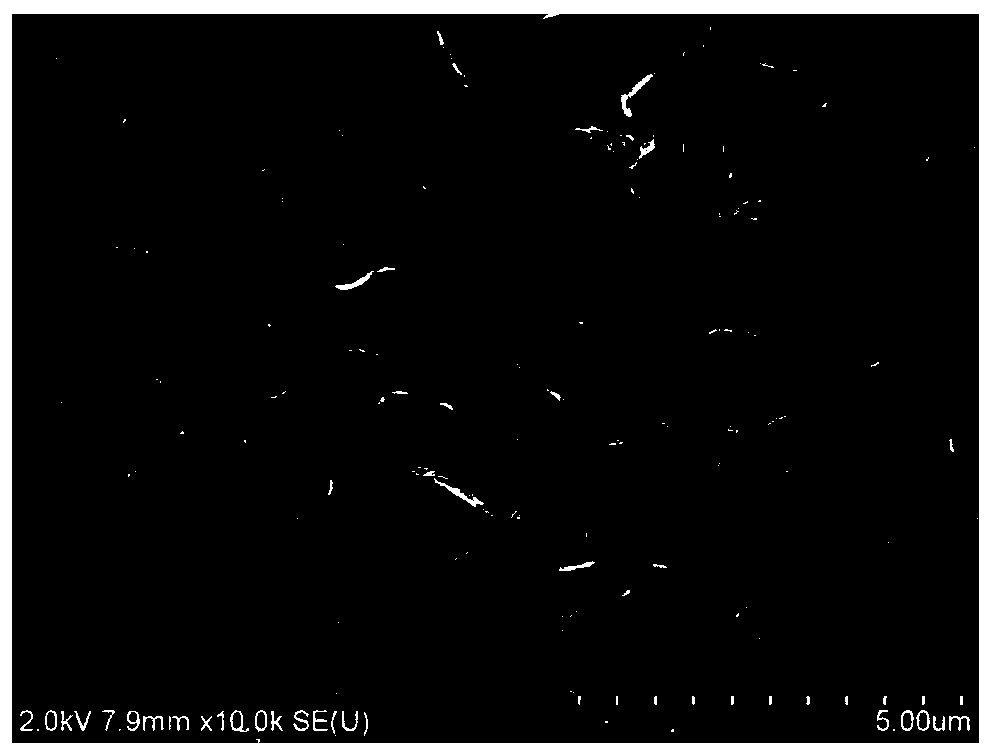

[0037] Such as figure 1Shown is t...

Embodiment 2

[0038] Example 2: High water resistance waterborne polyurethane / modified montmorillonite nanocomposite and film

[0039] The preparation of waterborne polyurethane / polyetheramine modified montmorillonite nanocomposite emulsion is as follows:

[0040] (1) Organic amine-polyetheramine 2000 is used to modify montmorillonite, the specific modification examples are as follows:

[0041] Weigh 1.0 g of montmorillonite, add 100 ml of distilled water to make a 1% montmorillonite dispersion, and swell for 1 hour. Magnetic stirring at room temperature for 60 minutes, ultrasonic dispersion for 30 minutes. Weigh 1.6g of polyetheramine, add appropriate amount of hydrochloric acid at room temperature, prepare the hydrochloric acid aqueous solution of polyetheramine, add it dropwise to the montmorillonite dispersion under strong stirring at 80°C, control the dropping time at 30min, and react for 5h , after the reaction is completed, naturally cool to normal temperature, filter; then wash wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| cation exchange capacity (equivalent) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com