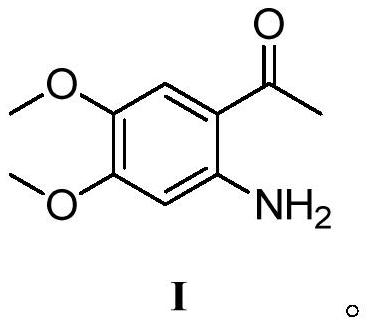

A kind of preparation method of the intermediate of tyrosine kinase inhibitor

A tyrosine kinase and inhibitor technology, which is applied in the field of intermediate preparation, can solve the problems of many impurities, low purity, and difficulty in purification, and achieve simplified post-processing, improved purity and yield, and mild reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

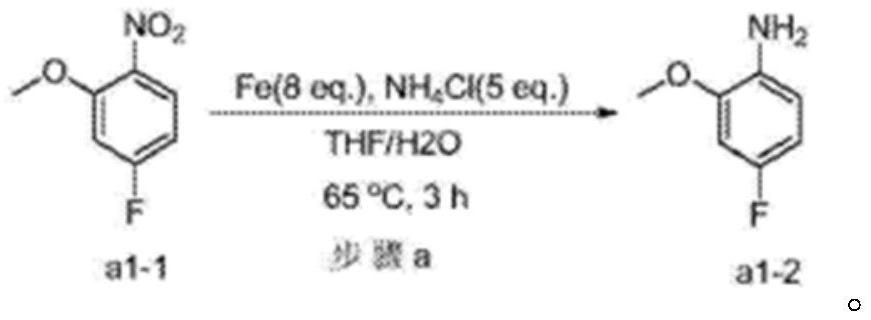

Method used

Image

Examples

Embodiment 1

[0023] 3.40 g (0.01510 mol) of compound II was placed in a 250 ml four-neck flask, and a mixed solution of ethyl acetate and water (34 ml / 20 ml) was added. At room temperature, 2.10 g (0.03925 mol, 2.6 eq) of ammonium chloride and 3.67 g (0.06553 mol, 4.34 eq) of reduced iron powder were successively added to the stirred reaction flask, and then the reaction system was heated to 40°C and stirred for 3 h . The progress of the reaction was checked by TLC. After the substrate is completely reacted, excess iron powder is filtered out. The filter cake was rinsed three times with 15 ml of ethyl acetate. The organic layer was separated from the filtrate, washed with saturated brine, and concentrated under reduced pressure to obtain 2.53 g of compound I, yield: 86%, HPLC purity: 99.7%.

Embodiment 2

[0025] 3.40 g of compound II was placed in a 250 ml four-neck flask, and a mixed solution of ethyl acetate and water (34 ml / 20 ml) was added. At room temperature, 3.55 g (0.06644 mol, 4.4 eq) of ammonium chloride and 5.92 g (0.1057 mol, 7 eq) of reduced iron powder were sequentially added to the stirred reaction flask, and then the reaction system was heated to 20° C. and stirred for 4 h. The progress of the reaction was checked by TLC. After the substrate is completely reacted, excess iron powder is filtered out. The filter cake was rinsed three times with 15 ml of ethyl acetate. The organic layer was separated from the filtrate, washed with saturated brine, and concentrated under reduced pressure to obtain 2.79 g of compound I, yield: 94.7%, HPLC purity: 99.2%.

Embodiment 3

[0027] 3.40 g (0.01510 mol) of compound II was placed in a 250 ml four-neck flask, and a mixed solution of ethyl acetate and water (34 ml / 20 ml) was added. At room temperature, 1.61g (0.0302mol, 2.0eq) of ammonium chloride and 2.54g (0.0453mol, 3.0eq) of reduced iron powder were successively added to the stirred reaction flask, and then the reaction system was heated to 30°C and stirred for 3h . The progress of the reaction was checked by TLC. After the substrate is completely reacted, excess iron powder is filtered out. The filter cake was rinsed three times with 15 ml of ethyl acetate. The organic layer was separated from the filtrate, washed with saturated brine, and concentrated under reduced pressure to obtain 2.65 g of compound I, yield: 90%, HPLC purity: 99.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com