Aluminum alloy stair

An aluminum alloy and step technology, which is applied in escalators, transportation and packaging, etc., can solve the problems of no uneven anti-skid effect on the surface of the pedal, inconvenient assembly and disassembly, inconvenient processing and production, etc., and achieves reliable safety performance and structure. Simple, weight-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

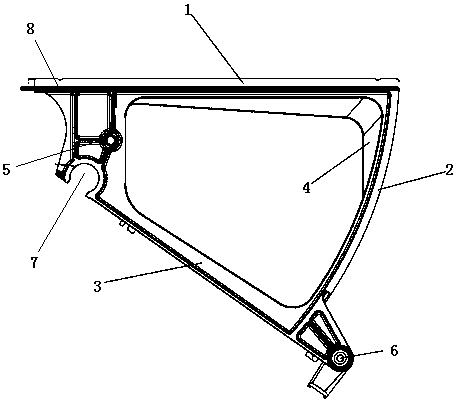

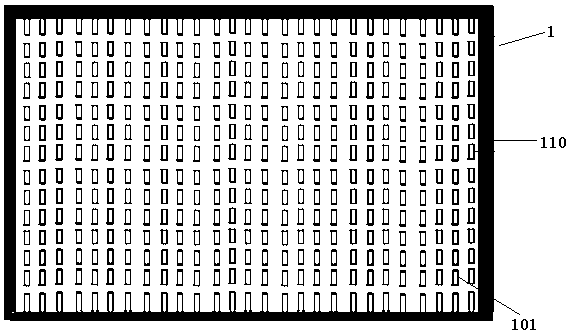

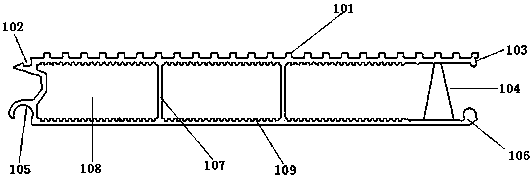

[0016] Example: such as figure 1 , figure 2 with image 3 As shown, an aluminum alloy step includes pedal 1, kick plate 2 and triangular frame 3, pedal 1, kick plate 2 and triangular frame 3 are formed by aluminum alloy die-casting, and triangular frame 3 is provided with driving wheel 5 and driven wheel 6 The bottom of the drive wheel 5 is provided with a semi-closed circular installation groove 7, and a number of anti-skid teeth 101 are evenly distributed on the upper surface of the pedal 1. The shape of the anti-skid teeth 101 is square or triangular, and upper chucks are respectively arranged at both ends of the upper surface of the pedal 1. 103 and the upper card slot 102, the two ends of the lower surface of the pedal 1 are respectively provided with the lower card head 106 and the lower card slot 105, the cross-sectional shape of the upper card head 103 is square, the upper card slot 102 is provided with a corresponding square groove, and the lower card slot 102 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com