Material arranging device

A magnetic field generating device and material channel technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of high labor intensity, easy to cut workers' palms, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below, but the embodiments of the present invention are not limited thereto.

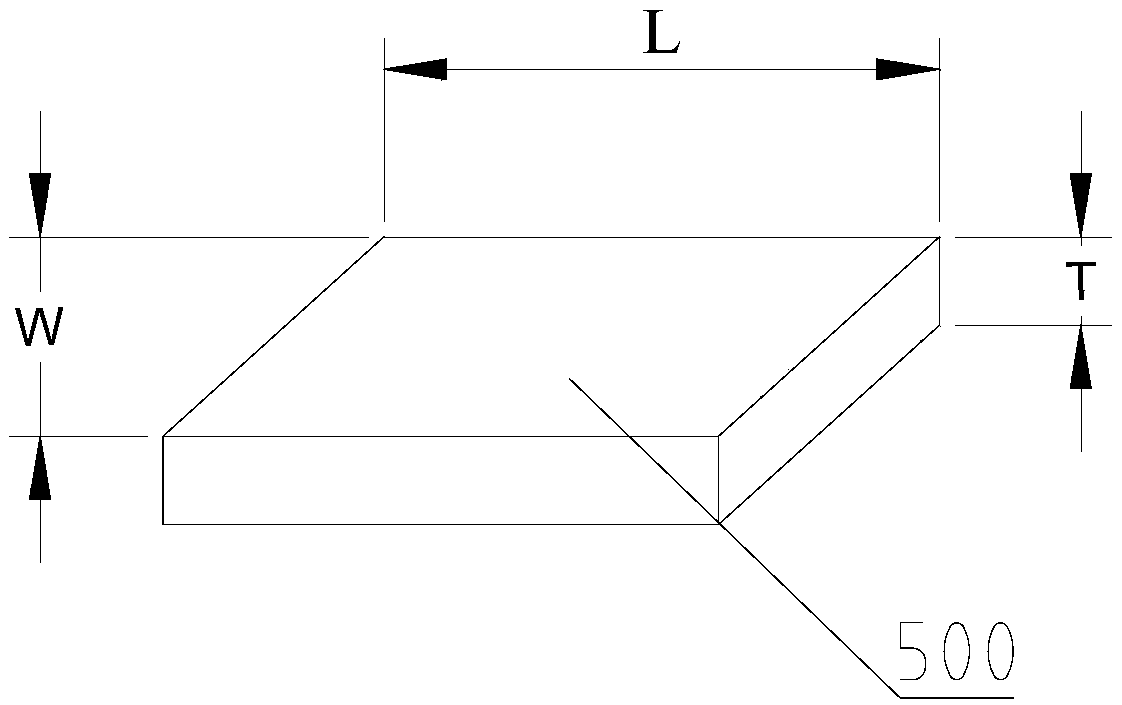

[0040] Such as figure 1 Shown is the material 500 used in this embodiment, length: L=32.4~32.5mm, width: W=5±0.04mm, thickness: T=0.6±0.02mm or 0.7±0.02mm or 0.8±0.03mm. But not limited thereto, other structures of the material 500 may also be used. It is preferable to adopt a structure that is easy to be magnetized, or a structure that is easy to be aligned in a specific direction by the magnetic field layer, such as a long sheet structure, or a long strip structure, or a structure with pointed ends at both ends.

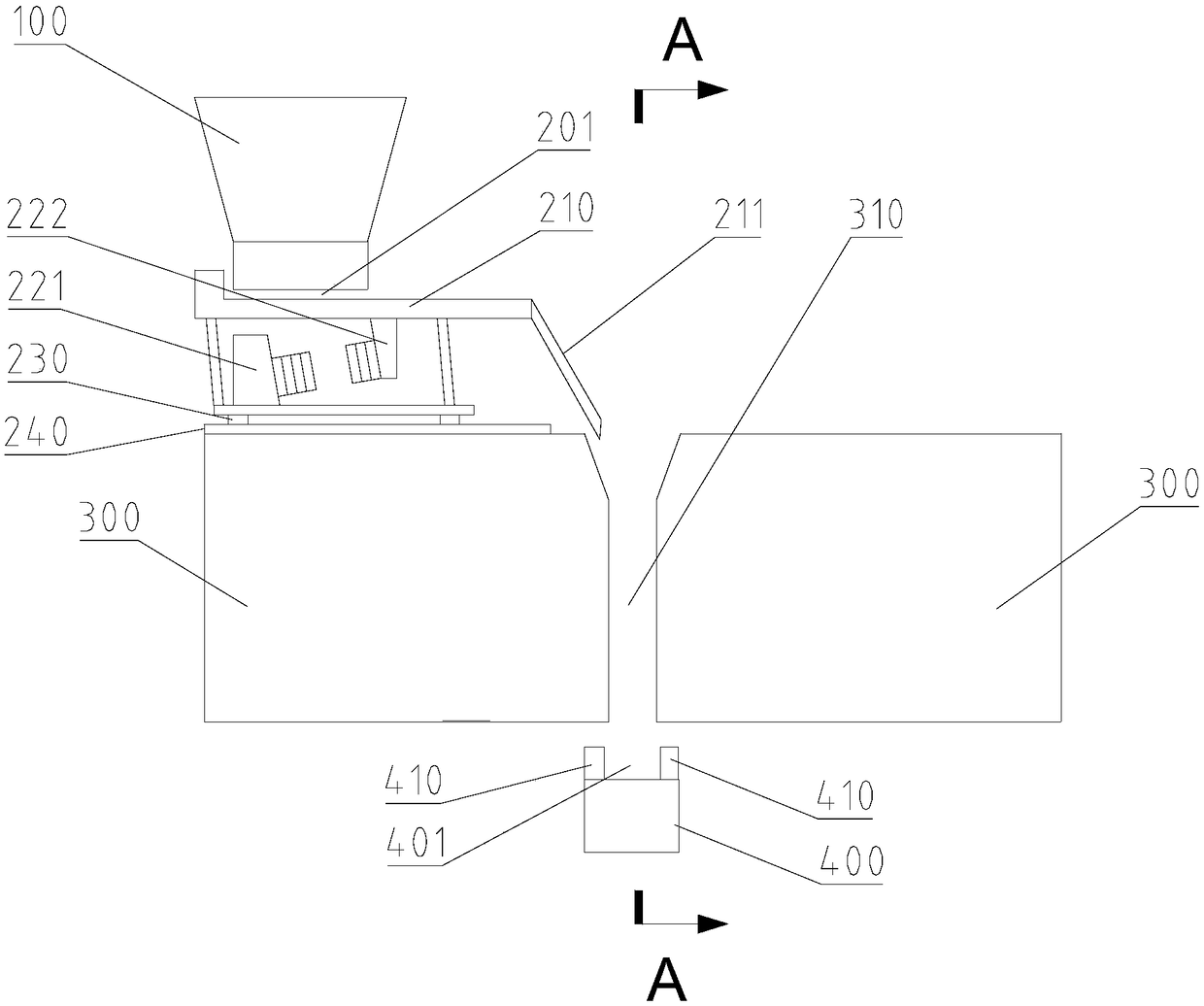

[0041] Such as figure 2 As shown, the discharge device includes: a feed mechanism, a discharge mechanism, and a discharge mechanism.

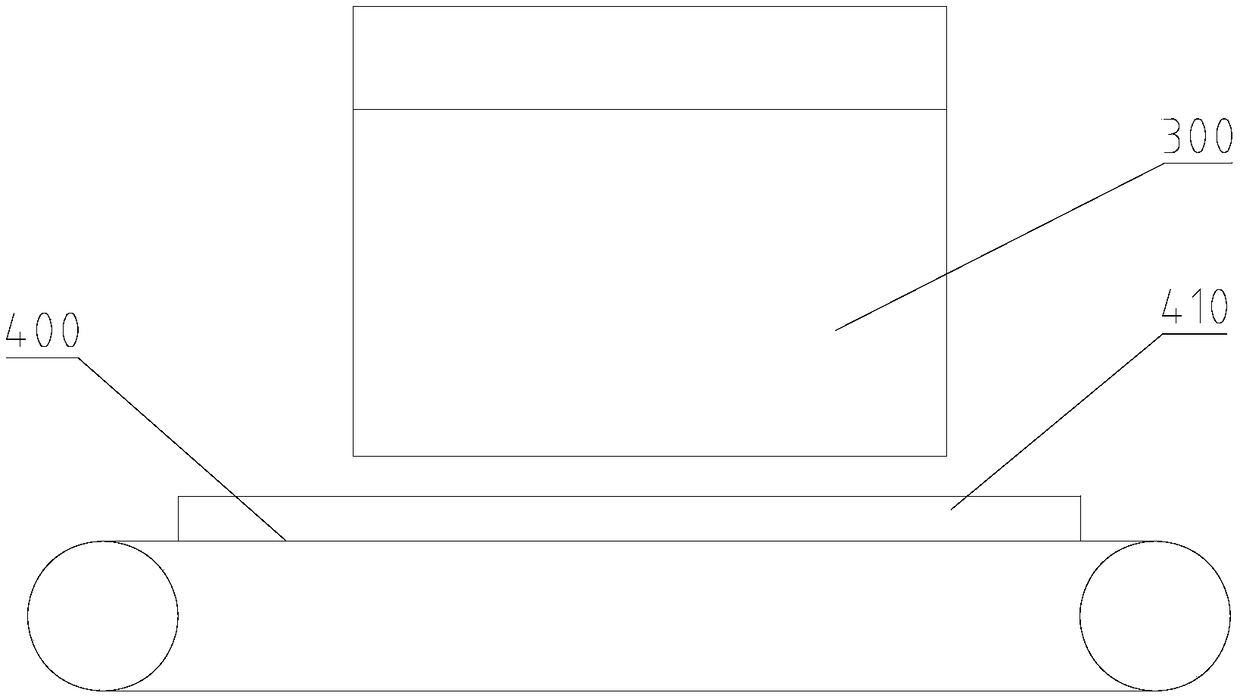

[0042] Such as figure 2 , 4 As shown, the feed mechanism is provided with a feed hopper 100, a swing mechanism, and a feed tray 210 docked with the swing mechanism. The feed hopper 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com