An electron beam fuse transition state maintenance system and maintenance method

A transitional state and system-maintaining technology, which is applied in the direction of process efficiency improvement, additive manufacturing, additive processing, etc., to achieve the effects of improving forming accuracy, avoiding poor forming, and improving dimensional accuracy and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

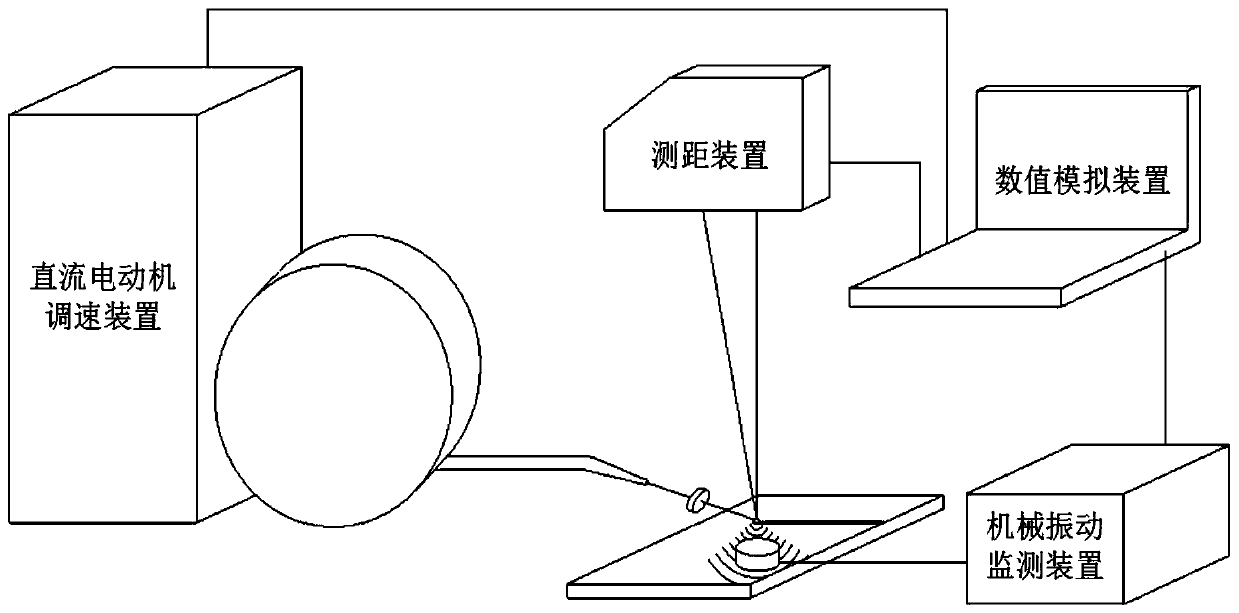

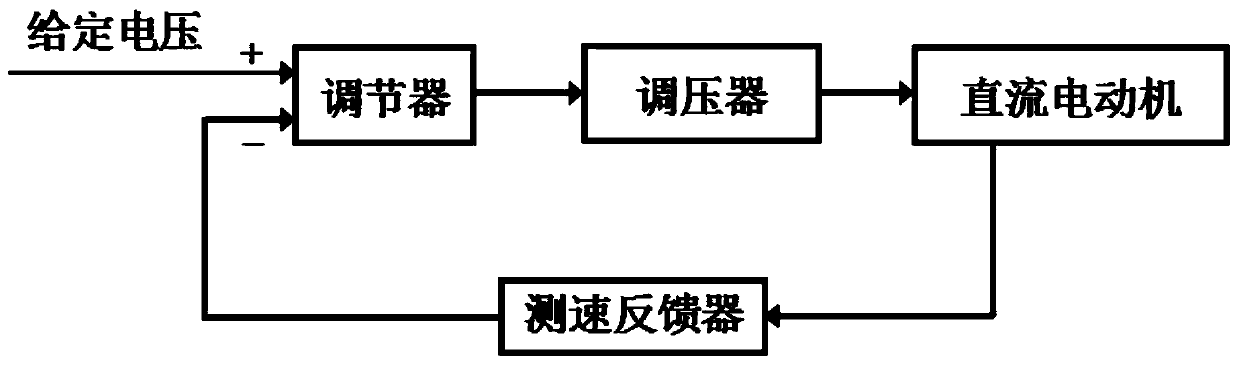

[0050] like figure 1 As shown, a kind of electronic beam fuse transition state maintenance system provided by the present invention includes a mechanical vibration monitoring device, a distance measuring device, a numerical simulation device and a DC motor speed regulating device;

[0051] The mechanical vibration monitoring device collects the vibration signal of the droplet transition state of the fuse in real time, and the numerical simulation device judges the fuse transition state of the electron beam additive manufacturing under the current state according to the vibration signal;

[0052] The distance measuring device measures the height information, and the numerical simulation device simulates the transition state of the fuse at different wire feeding speeds according to the height information, and screens out the corresponding wire feeding spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com