A method for quickly removing paraffin in the dehydration box

A paraffin, fast technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems affecting the normal use of dehydration boxes, environmental pollution of paraffin, and waste of paraffin, and achieve good removal effect, The effect of improving the penetration and improving the removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

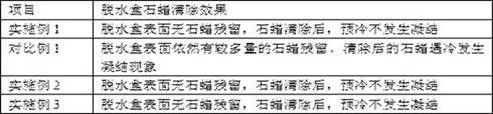

Examples

Embodiment 1

[0017] A method for quickly removing paraffin in a dehydration box, comprising the following steps:

[0018] (1) In parts by weight, in-situ polymerized nano-hybrid silicone oil, sodium methacrylate sulfonate, and deionized water were uniformly mixed in a mass ratio of 10:1:20, and then ultrasonically treated for 28 minutes to obtain the solution release agent;

[0019] (2) In parts by weight, add 14 parts of 1,2-cyclohexanediaminetetraacetic acid, 3 parts of methyl D-lactate, and 16 parts of diethylene glycol chloroformate into 75 parts of ethanol, mix and stir evenly , and then add 8 parts of the dissociating agent prepared in step (1), and continue to stir and mix evenly to obtain a paraffin removal solution;

[0020] (3) Put the dehydration box into warm water at 40°C, soak for 3 minutes, take out the dehydration box, use filter paper to quickly absorb the moisture on the surface of the dehydration box, and then spray paraffin removal solution on the surface of the dehydr...

Embodiment 2

[0026] A method for quickly removing paraffin in a dehydration box, comprising the following steps:

[0027] (1) In parts by weight, in-situ polymerized nano-hybrid silicone oil, sodium methacrylate sulfonate, and deionized water were uniformly mixed in a mass ratio of 13:1:20, and then ultrasonically treated for 30 minutes to obtain the solution release agent;

[0028] (2) In parts by weight, add 17 parts of 1,2-cyclohexanediaminetetraacetic acid, 5 parts of methyl D-lactate, and 18 parts of diethylene glycol chloroformate into 80 parts of ethanol, mix and stir evenly , and then add 9 parts of the dissociating agent prepared in step (1), and continue to stir and mix evenly to obtain a paraffin removal solution;

[0029] (3) Put the dehydration box into warm water at 45°C, soak for 4 minutes, take out the dehydration box, use filter paper to quickly absorb the moisture on the surface of the dehydration box, and then spray paraffin removal solution on the surface of the dehydr...

Embodiment 3

[0035] A method for quickly removing paraffin in a dehydration box, comprising the following steps:

[0036] (1) In parts by weight, in-situ polymerized nano-hybrid silicone oil, sodium methacrylate sulfonate, and deionized water were uniformly mixed in a mass ratio of 15:1:20, and then ultrasonically treated for 32 minutes to obtain the solution release agent;

[0037] (2) In parts by weight, add 19 parts of 1,2-cyclohexanediaminetetraacetic acid, 6 parts of methyl D-lactate, and 20 parts of diethylene glycol chloroformate into 85 parts of ethanol, mix and stir evenly , and then add 10 parts of the dissociating agent prepared in step (1), and continue to stir and mix evenly to obtain a paraffin removal solution;

[0038] (3) Put the dehydration box into warm water at 50°C, soak for 5 minutes, take out the dehydration box, use filter paper to quickly absorb the water on the surface of the dehydration box, and then spray paraffin removal solution on the surface of the dehydrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com