Pipette tip for sucking viscous liquid and preparation method thereof

A technology for viscous liquids and pipettes, which is applied in measuring tubes/pipettes, chemical instruments and methods, and laboratory containers. Reduced accuracy and other issues, to achieve the effect of improving practical value, convenient observation, and accurate volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

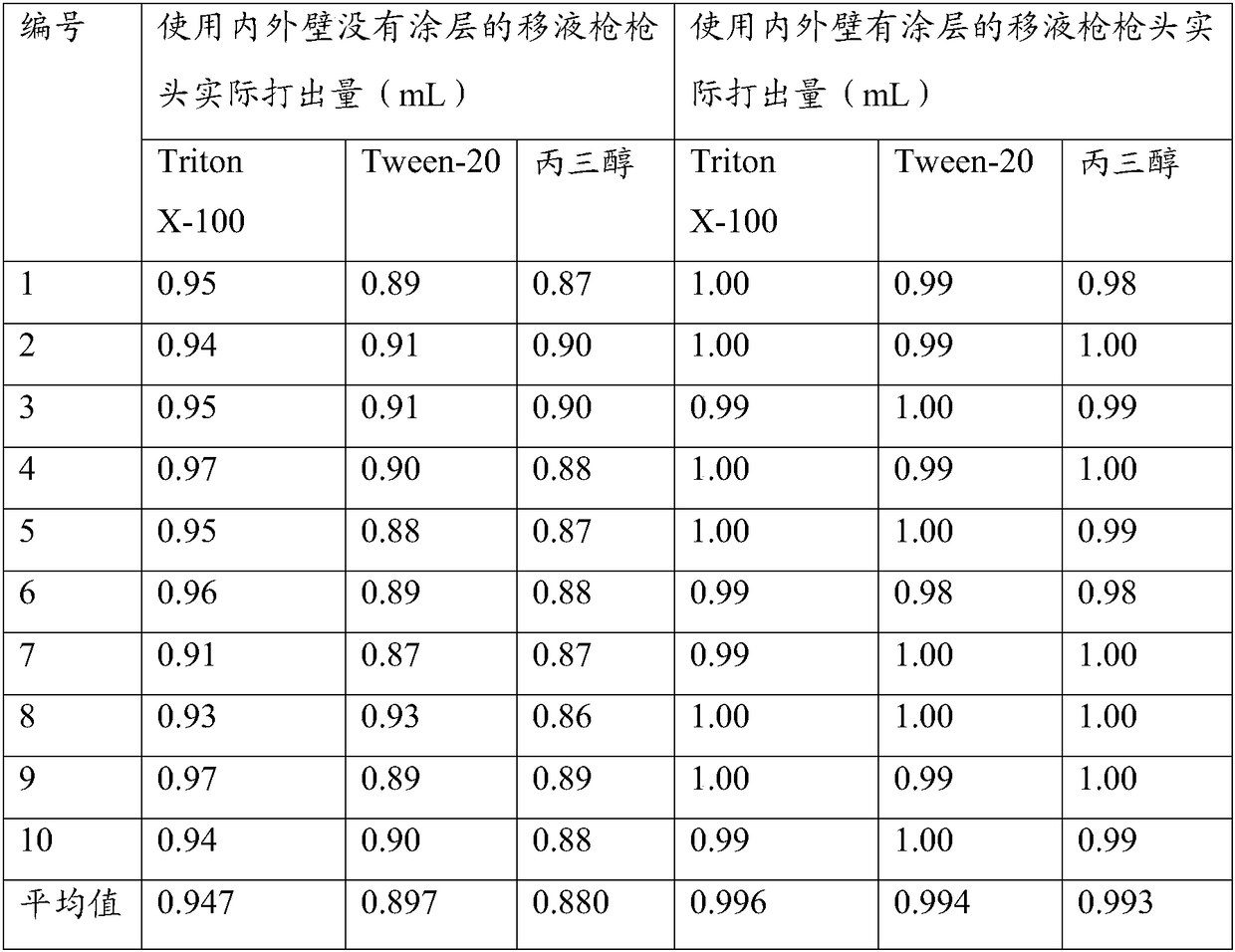

[0024] (1) At room temperature of 25°C, using xylene as a solvent, 15% of the mass fraction of nano-silica with a particle diameter of 50nm and 20% of the mass fraction of aminoacrylic acid resin are mixed at high speed to obtain aminoacrylic resin containing Coating solution with nano silica.

[0025] (2) Spray the coating solution that step (1) obtains evenly on the inner and outer surfaces of the pipette tip with a sprayer, and put the pipette tip after the spraying into a drying box to dry naturally, so that the pipette gun The inner and outer surfaces of the head have nanometer-sized protruding structures formed by compounding the aminoacrylic resin and nano silicon dioxide.

[0026] (3) Use a sprayer to spray a thin layer of tridecafluorooctyltriethoxysilane solution on the inner and outer surfaces of the pipette tip dried in step (2), and put it in an oven after standing for 30 minutes, at 60°C After curing for 2 hours, a superhydrophobic and oleophobic coating with go...

Embodiment 2

[0030] (1) At room temperature of 25°C, using acetate as a solvent, mix 20% of the mass fraction of nano-titanium dioxide with a particle size of 300nm and 30% of the mass fraction of aminoacrylic resin under high-speed shearing and stirring to obtain a mixture containing aminoacrylic resin and nano Coating solution of titanium dioxide.

[0031] (2) Spray the coating solution that step (1) obtains evenly on the inner and outer surfaces of the pipette tip with a sprayer, and put the pipette tip after the spraying into a drying box to dry naturally, so that the pipette gun The inner and outer surfaces of the head have nanometer-sized protruding structures formed by compounding aminoacrylic resin and nano-titanium dioxide.

[0032] (3) Spray a thin layer of perfluorodecyltriethoxysilane solution on the inner and outer surfaces of the pipette tip dried in step (2) with a sprayer, put it in an oven after standing for 30 minutes, and cure at 60°C After 2 hours, a superhydrophobic a...

Embodiment 3

[0034] (1) At room temperature of 25°C, using butanol as a solvent, the nano-zinc oxide with a mass fraction of 15% of a particle diameter of 500nm and the aminoacrylic resin with a mass fraction of 40% are mixed under high-speed shear to obtain a mixture containing aminoacrylic resin and Coating solution of nano zinc oxide.

[0035] (2) Spray the coating solution obtained in step (1) evenly on the inner and outer surfaces of the pipette tip with a sprayer, and put the sprayed pipette tip into a drying oven to dry naturally. Therefore, the inner and outer surfaces of the tip of the pipette have a nanometer-sized protrusion structure formed by compounding the aminoacrylic resin and nano-zinc oxide.

[0036] (3) Spray a thin layer of perfluorodecyltriethoxysilane solution on the inner and outer surfaces of the pipette tip dried in step (2) with a sprayer, put it in an oven after standing for 30 minutes, and cure at 60°C After 2 hours, a superhydrophobic and oleophobic coating w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com