Method of synchronously stabilizing heavy metals and degrading polycyclic aromatic hydrocarbons from waste incineration fly ash

A technology for waste incineration fly ash and polycyclic aromatic hydrocarbons, which is applied in chemical instruments and methods, transportation and packaging, solid waste removal, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

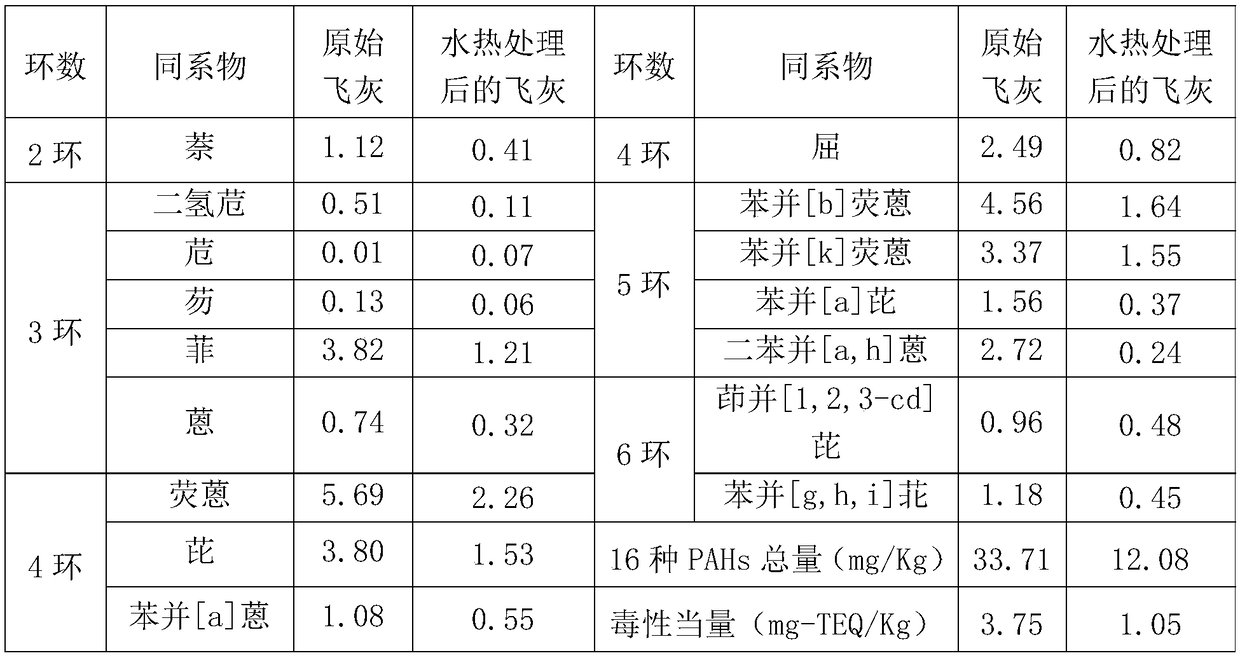

Embodiment 1

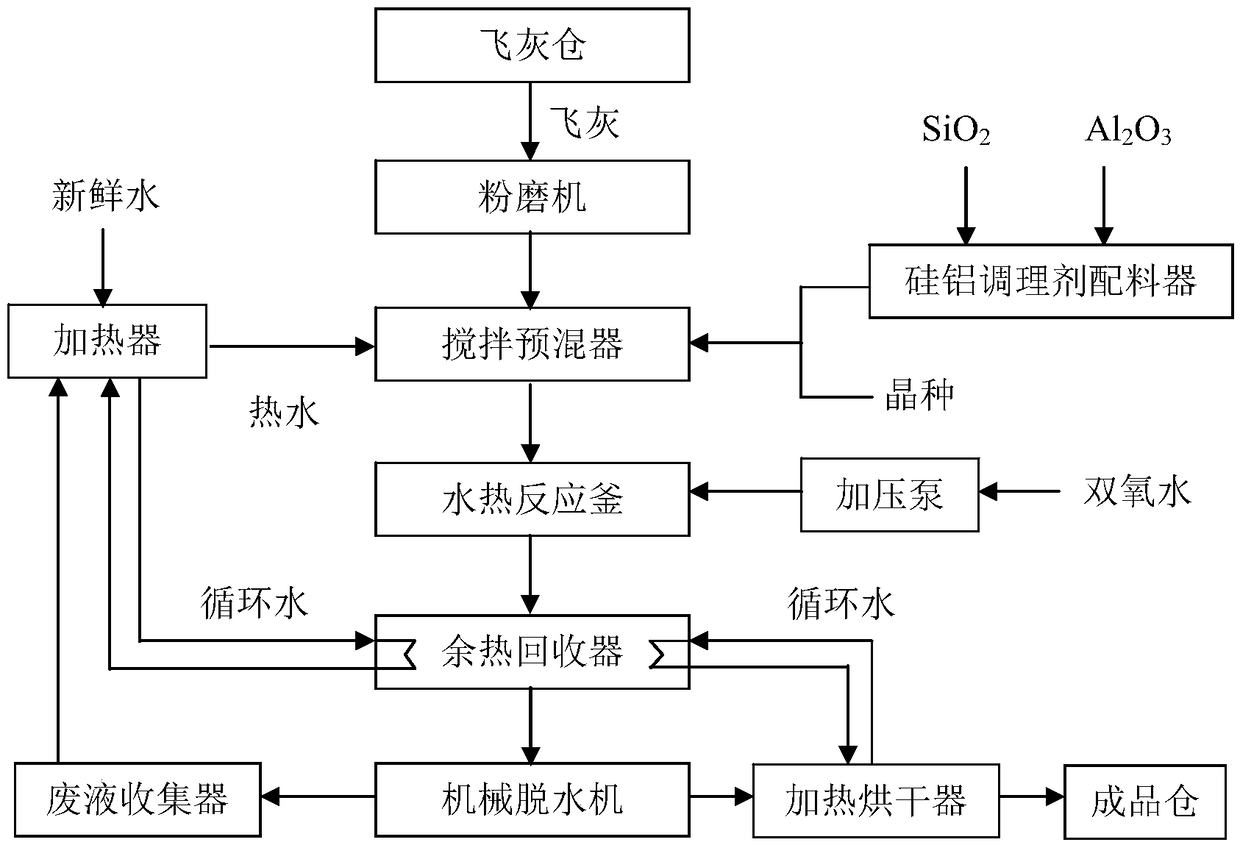

[0029] The method for synchronously stabilizing heavy metals and degrading polycyclic aromatic hydrocarbons in the waste incineration fly ash of this embodiment comprises the following steps:

[0030] 1) Pretreatment: transfer the fly ash in the fly ash bin to the pulverizer, and use the pulverizer to grind the fly ash to make the particle size equal to 80 μm;

[0031] 2) Deployment: transfer the pretreated fly ash to a stirring pre-mixer, add silicon-aluminum conditioner and hot water to the stirring pre-mixer, and obtain a mixture liquid after stirring for 10 hours. The molar content ratio between calcium, silicon and aluminum elements in the liquid meets the generation requirement of zeolite aluminosilicate mineral tobermorite, and the liquid-solid ratio of water and mixed ash sample in the mixed material liquid is 10: 1mL / g; Wherein, the silicon-aluminum conditioning agent is configured through the silicon-aluminum conditioning agent batching device, and the silicon-alumin...

Embodiment 2

[0040] The method for synchronously stabilizing heavy metals and degrading polycyclic aromatic hydrocarbons in the waste incineration fly ash of this embodiment comprises the following steps:

[0041] 1) Pretreatment: transfer the fly ash in the fly ash bin to the pulverizer, and use the pulverizer to grind the fly ash to make the particle size equal to 75 μm;

[0042] 2) Deployment: Transfer the pretreated fly ash to a stirring pre-mixer, add silicon-aluminum conditioner and hot water to the stirring pre-mixer, and obtain a mixed material liquid after stirring for 9 hours. The mixed material The molar content ratio between calcium, silicon and aluminum elements in the liquid meets the generation requirement of zeolite aluminosilicate mineral tobermorite, and the liquid-solid ratio of water and mixed ash sample in the mixed material liquid is 8: 1mL / g; Wherein, the silicon-aluminum conditioning agent is configured through the silicon-aluminum conditioning agent batching device...

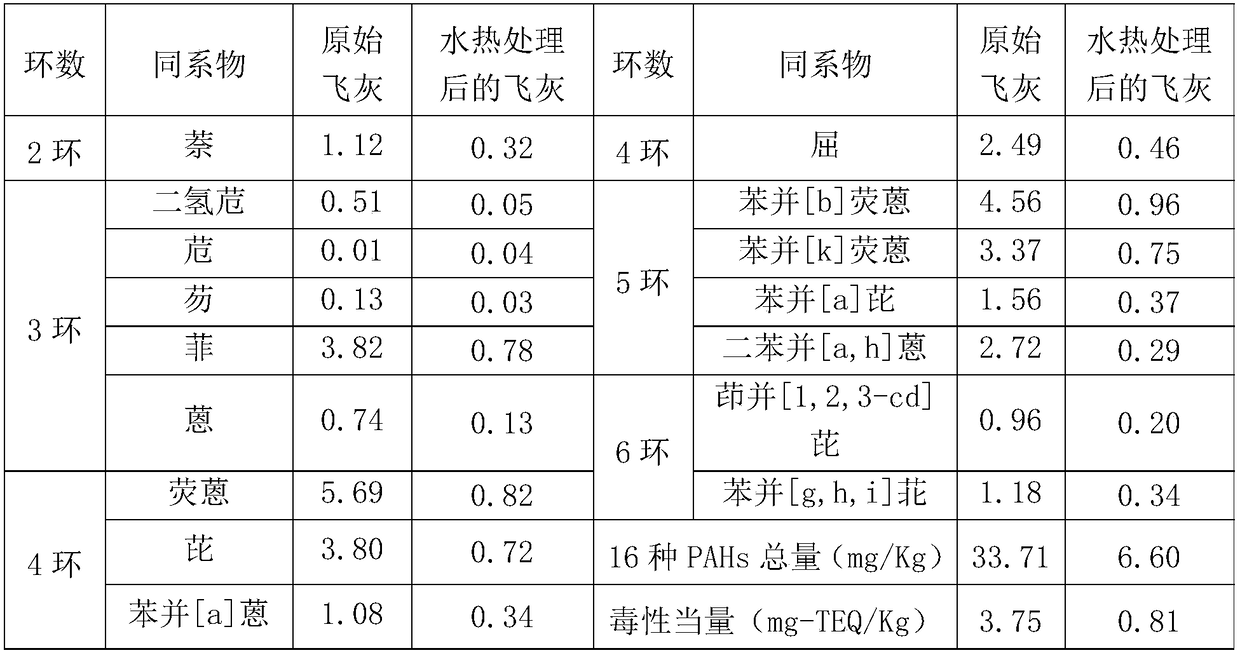

Embodiment 3

[0051] The method for synchronously stabilizing heavy metals and degrading polycyclic aromatic hydrocarbons in the waste incineration fly ash of this embodiment comprises the following steps:

[0052] 1) Pretreatment: transfer the fly ash in the fly ash bin to the pulverizer, and use the pulverizer to grind the fly ash to make the particle size equal to 77 μm;

[0053] 2) Deployment: transfer the pretreated fly ash to a stirring pre-mixer, add silicon-aluminum conditioner and hot water to the stirring pre-mixer, and obtain a mixture liquid after stirring for 10 hours. The molar ratio between calcium, silicon and aluminum elements in the liquid meets the generation requirements of the zeolite aluminosilicate mineral tobermorite, and the liquid-solid ratio of water and mixed ash sample in the mixed material liquid is 5: 1mL / g; Wherein, the silicon-aluminum conditioning agent is configured through the silicon-aluminum conditioning agent batching device, and the silicon-aluminum c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com