Preparation method and application of graphene coated lead-lead oxide composite material

A technology of graphene coating and lead oxide, which is applied in the direction of lead-acid batteries, electrical components, battery electrodes, etc., can solve the problems of low utilization efficiency and uneven material mixing, so as to improve utilization efficiency and redox efficiency , The effect that the production process conditions are easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

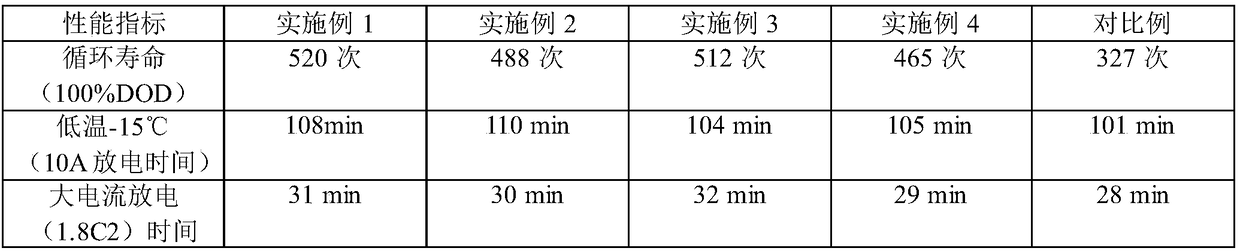

Examples

Embodiment 1

[0038] (1) According to the mass ratio of 0.5:2.5:62, graphene oxide, conjugated redox polymer and lead-lead oxide were weighed respectively for use, and graphene oxide was pretreated: soak graphene oxide in analytically pure In sulfuric acid, stirred at 35°C for 5h, the liquid-solid ratio of sulfuric acid to graphene oxide was 40mL / g;

[0039] (2) lead-lead oxide is carried out ball milling in ball milling lead powder machine;

[0040] (3) Mix the pretreated graphene oxide and conjugated redox polymer into the lead-lead oxide being ball-milled in the ball-milling lead powder machine through the tuyere, and under the temperature of 150°C, 30KHz frequency ultrasonic stirring conditions , the reaction generates graphene-coated lead-lead oxide composites; wherein, the flow rate of graphene oxide blowing is controlled at 45m 2 / min, the graphene oxide content per unit volume is 5g / m 3 ;

[0041] (4) The prepared graphene layer-coated lead-lead oxide composite material is mixed in...

Embodiment 2

[0043] (1) According to the mass ratio of 1.2:3.8:105, respectively weigh graphene oxide, conjugated redox polymer and lead-lead oxide for use, and pretreat graphene oxide: soak graphene oxide in analytically pure In sulfuric acid, stirred at a temperature of 52°C for 2h, the liquid-solid ratio of the sulfuric acid to graphene oxide was 50mL / g;

[0044] (2) lead-lead oxide is carried out ball milling in ball milling lead powder machine;

[0045] (3) Mix the pretreated graphene oxide and conjugated redox polymer into the lead-lead oxide being ball-milled in the ball-milling lead powder machine through the tuyere, under the temperature condition of 180 ℃, 10KHz frequency ultrasonic stirring condition , the reaction generates graphene-coated lead-lead oxide composite materials; wherein, the flow rate of graphene oxide blowing is controlled at 80m 2 / min, the graphene oxide content per unit volume is 18g / m 3 ;

[0046] (4) The prepared graphene layer-coated lead-lead oxide comp...

Embodiment 3

[0048] (1) According to the mass ratio of 1:3:80, graphene oxide, conjugated redox polymer and lead-lead oxide were weighed respectively for use, and graphene oxide was pretreated: immerse graphene oxide in analytically pure In sulfuric acid, stirred at 45°C for 3h, the liquid-solid ratio of the sulfuric acid to graphene oxide was 45mL / g;

[0049] (2) lead-lead oxide is carried out ball milling in ball milling lead powder machine;

[0050] (3) Mix the pretreated graphene oxide and conjugated redox polymer into the lead-lead oxide being ball-milled in the ball-milling lead powder machine through the tuyere, and under the temperature of 170°C, 20KHz frequency ultrasonic stirring conditions , the reaction generates graphene-coated lead-lead oxide composite materials; wherein, the flow rate of graphene oxide blowing is controlled at 70m 2 / min, the graphene oxide content per unit volume is 10g / m 3 ;

[0051] (4) The prepared graphene layer-coated lead-lead oxide composite mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com