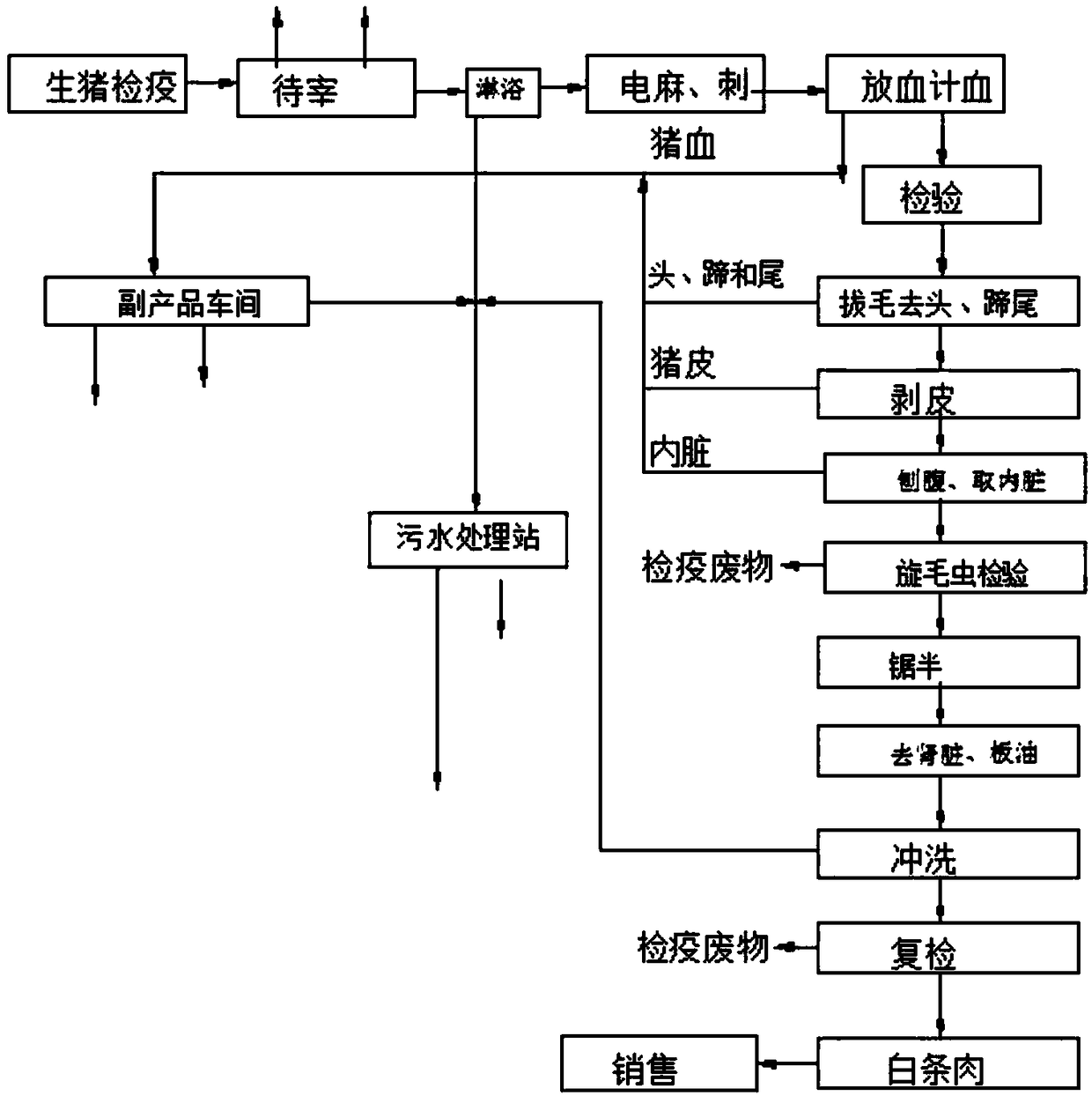

Pork slaughtering processing technological process

A technological process and pork technology, applied in the field of pork slaughtering and processing technological processes, can solve the problems of polluting the environment, wasting by-products, and cleaning up to the standard, etc., and achieve the effects of improving economic efficiency, strong purification effect, and increasing utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The invention provides a technological process for slaughtering and processing pork, comprising the following steps:

[0030] Step 1: Quarantine of live pigs. The live pigs come from farms and farmers that are not in the blockade area or where no relevant animal epidemics have occurred. File-related records and livestock and poultry identification comply with the regulations, and the clinical examination is healthy;

[0031] Step 2: To be slaughtered, the pigs to be slaughtered should stop eating and rest for 12-24 hours before sending them to slaughter, so as to eliminate fatigue during transportation and restore their normal physiological state;

[0032] Step 3: Shower, shower the pigs;

[0033] Step 4: Stunning by anesthesia;

[0034] Step 5: Assassination and bloodletting, the stunned piglet is tied to one hind leg with a buckle ankle chain, and the piglet is lifted into the track of the piglet bloodletting automatic conveying line through the piglet lifting devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com