Scrapping method of printed circuit board

A technology for printed circuit boards and circuits, applied in the directions of printed circuits, printed circuit manufacturing, sorting, etc., can solve the problems of short circuit of copper scraps, large investment, scrapping, etc., to achieve high yield, avoid leakage, and high production efficiency. Effect

Active Publication Date: 2018-10-26

HUIZHOU ZHONGJING ELECTRONICS TECH CO LTD

View PDF8 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] There are two main methods of scrapping traditional printed circuit boards: 1. Destructive scrapping methods (punching / pneumatic pen grinding, etc.), such methods are prone to produce copper scraps and cause abnormalities such as short circuits, resulting in unnecessary scrapping; 2. Scratching Line marking scrapping method (white paint pen, etc.), the materials used in this method are not quick-drying, it takes a certain time to dry or dry, must have personnel, space and equipment, and affect the turnover efficiency of the production line

With the development of science and technology, the line width and spacing are becoming denser and denser, and the impact of copper shavings on the yield rate is also increasing; at the same time, personnel, space and equipment require greater investment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0036] A method for scrapping printed circuit boards is characterized in that it comprises the following steps:

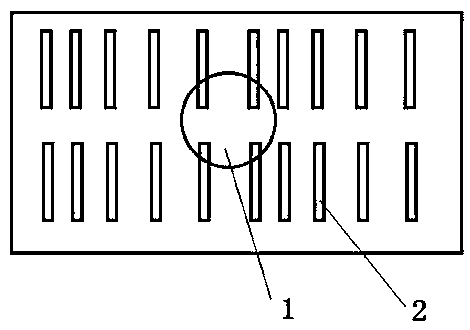

[0037] S1. The pre-processing step, the finished printed circuit board is obtained after the pre-processed step, and the finished printed circuit board is provided with copper stickers 2;

[0038] S2. Appearance inspection of copper stickers;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

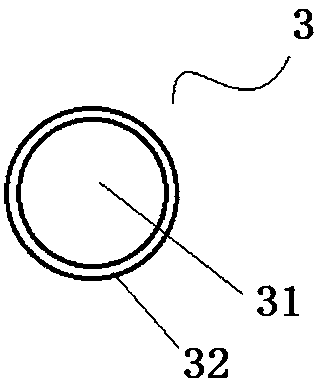

The invention provides a scrapping method of printed circuit boards. The method is characterized in that the method comprises following steps of S1, a preprocessing step: acquiring a printed circuit board finished product after the preprocessing step, wherein a copper patch is arranged on the printed circuit board finished product; S2, appearance examination of the copper patch; S3, electrical performance test: carrying out electrification test on the printed circuit board finished product; and S4: carrying out scrapping processing on a printed circuit board with abnormal appearance in the step S2 or on a circuit board which fails to pass the electrical performance test, wherein the printed circuit board comprises conductive copper patch with a copper skin layer and a rubber layer, and connecting the conductive copper patch with the copper patch so as to allow the conductive copper patch to be conducted with a circuit diagram layer of the printed circuit board to form a short circuit,thereby finishing scrapping of the printed circuit board. According to the invention, the yield of the product is high; the production cost is low; and production efficiency is high.

Description

technical field [0001] The invention belongs to the technical field of circuit board processing, and in particular relates to a scrapping method for printed circuit boards. Background technique [0002] Printed circuit board (referred to as PCB) is an important part of electronic products. In recent years, with the development of the electronics industry, the production of printed circuit boards has developed extremely rapidly. During the processing of printed circuit boards, some scrapped or unqualified intermediate products of circuit boards are often produced. These scrapped intermediate products are crushed to obtain copper-containing dust, and the copper content is as high as 20-30%. The remaining organic materials are mainly Glass fiber, if these wastes are directly incinerated, landfilled or discarded, it will not only waste resources, but also cause serious pollution to the environment. It is a major event of strategic significance to realize the resource utilizatio...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H05K3/00B07C5/344

CPCB07C5/344H05K3/00H05K2203/178

Inventor 余小丰杨俊黄晓生曾锐

Owner HUIZHOU ZHONGJING ELECTRONICS TECH CO LTD

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com