Phase-change hot pipe and liquid circulated cooling composite cooling device

A technology of liquid circulation and heat dissipation device, applied in the direction of transformer/inductor cooling, etc., can solve problems such as system outage, and achieve the effect of reducing volume, enhancing cooling effect, and increasing operating load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

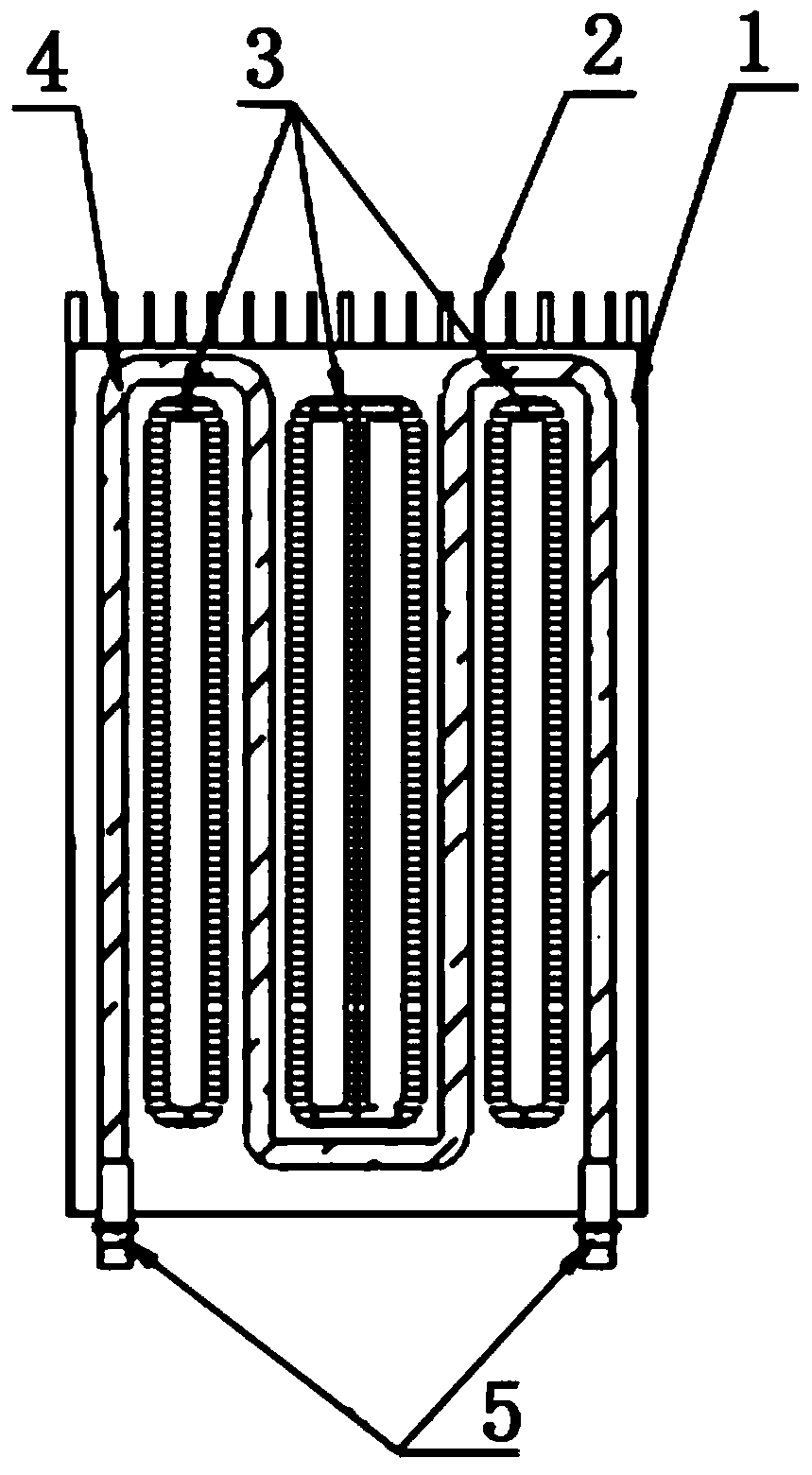

[0033] See figure 1 , figure 2 , phase change heat pipe 3 and liquid circulation cooling composite cooling device, including liquid circulation cooling system, phase change heat pipe 3 cooling system, the two systems are arranged alternately, the liquid circulation cooling system is composed of liquid cooling circulation loop 4, phase change heat pipe 3 The heat dissipation system is a phase change heat pipe 3; the liquid cooling circulation loop 4 is arranged in a serpentine shape, and several phase change heat pipes 3 are arranged between the liquid cooling circulation loop 4 and are close to the liquid cooling circulation loop 4. The phase change heat pipe 3 is annular or The sun-shaped structure, the liquid cooling circulation loop 4 and the phase change heat pipe 3 are arranged in the same plane, and the two ends of the liquid cooling circulation loop 4 are provided with a cooling liquid inlet and outlet 5 . The liquid cooling circulation circuit 4 and the phase change ...

Embodiment 2

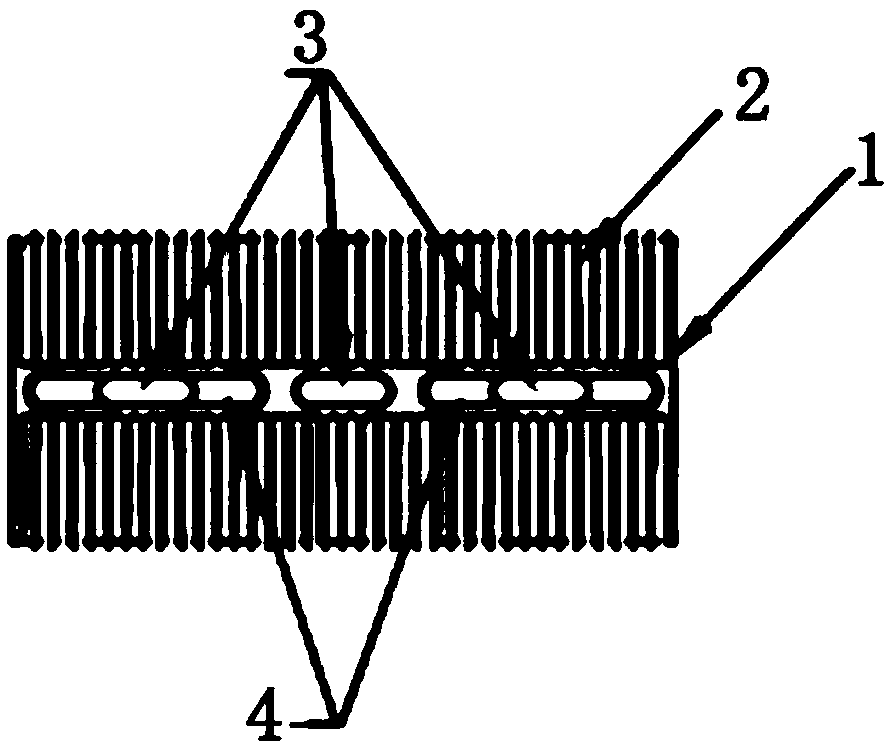

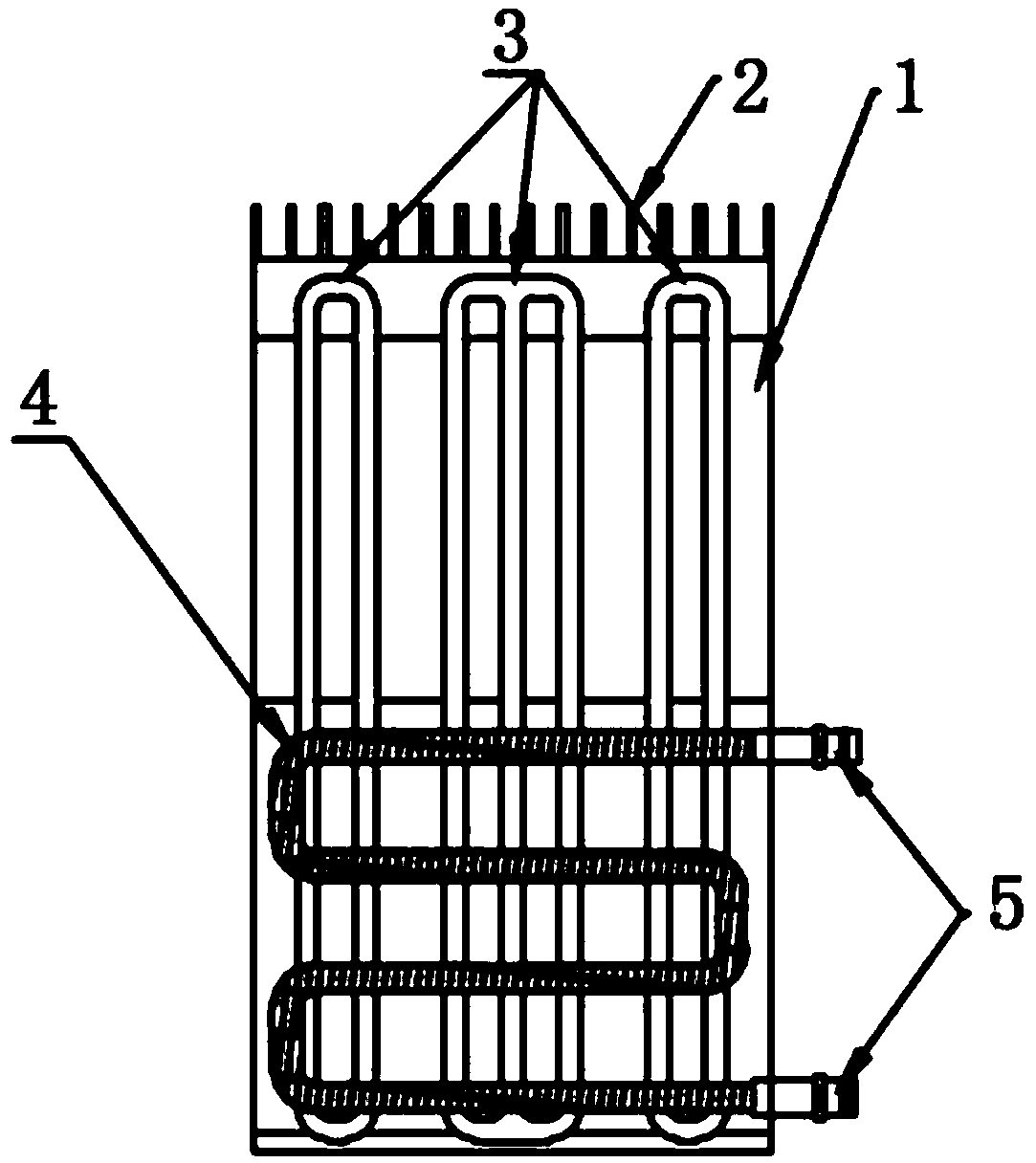

[0037] See image 3 , Figure 5 , the phase change heat pipe 3 and the liquid circulation cooling compound heat dissipation device, including the liquid circulation cooling system and the phase change heat pipe 3 heat dissipation system, the two systems are stacked and arranged in a composite manner, and the liquid circulation cooling system is composed of the liquid cooling circulation loop 4. The heat dissipation system of the heat pipe 3 is composed of several phase change heat pipes 3; the liquid cooling circulation loop 4 is arranged in a serpentine shape and fixed on the body 1; several phase change heat pipes 3 are arranged side by side in the body 1; The cooling circulation circuits 4 are stacked and installed, and the liquid cooling circulation circuits 4 are arranged on both sides of the body 1 . The liquid cooling circuit 4 can be arranged vertically, see image 3 ; The liquid cooling circuit 4 can also be arranged horizontally, see Figure 4 . Both ends of the ...

Embodiment 3

[0039] See Image 6 , Figure 7 , phase change heat pipe 3 and liquid circulation cooling composite cooling device, including liquid circulation cooling system, phase change heat pipe 3 cooling system, the two systems are nested together, the liquid circulation cooling system is liquid cooling circulation loop 4, phase change heat pipe 3 The heat dissipation system is a phase-change heat pipe 3; the cross section of the liquid cooling circulation loop 4 is ring-shaped, and the phase-change heat pipe is nested in the liquid cooling circulation loop 4, and the cooling liquid is passed through the ring structure, and the liquid cooling circulation loop 4 is fixed inside the body 1, and the body 1 Radiating fins 2 are fixed on the outside; a phase-changing heat pipe is arranged at the center of the liquid cooling circulation loop 4 . A capillary liquid-absorbing wick may also be arranged in the evaporation chamber of the phase-change heat pipe 3 .

[0040] In the above-mentioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com