XLPE cable water tree accelerated aging tester and sample manufacturing method

A technology of accelerated aging and test equipment, which is applied in the direction of measuring equipment, measuring electricity, and measuring electrical variables, etc. It can solve problems such as water tree aging, cable insulation breakdown failure, and affecting the safe and stable operation of cable lines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

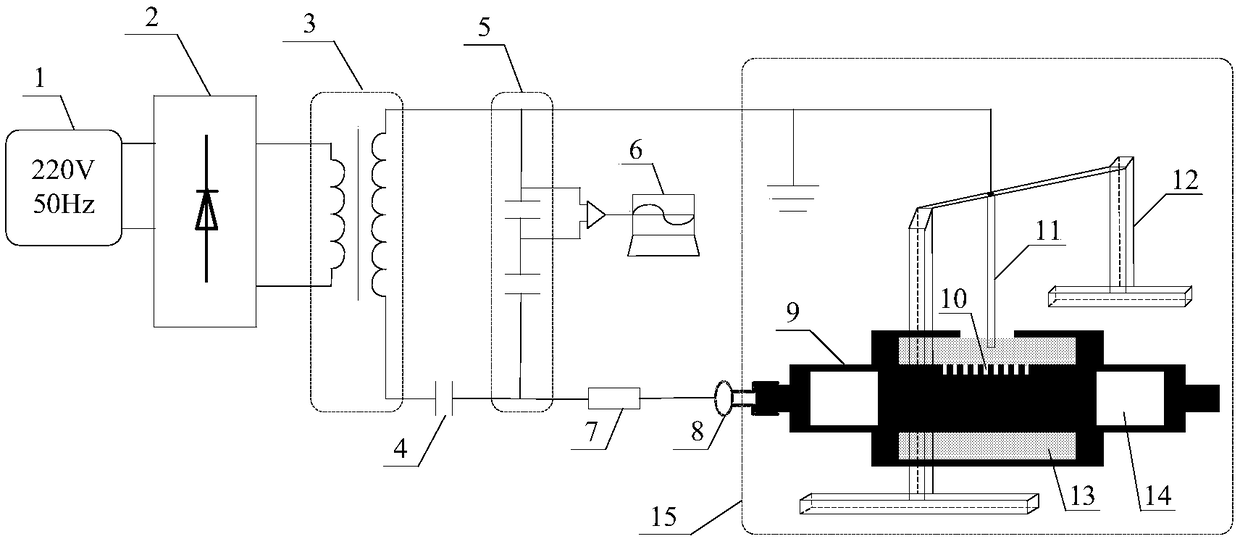

[0026] figure 1 A structural diagram of an XLPE cable water tree accelerated aging test device according to a preferred embodiment of the present invention is shown.

[0027] Such as figure 1 As shown, the XLPE cable water tree accelerated aging test device in this embodiment includes a voltage generation monitoring unit and an XLPE cable sample unit 15, and the XLPE cable sample unit 15 includes: a heat shrinkable sleeve 9, a connecting steel sheet 11, and a ground wire support 12. NaCl solution 13 and XLPE cable 14. The voltage generation monitoring unit includes: AC power supply 1 , frequency conversion unit 2 , intermediate transformer 3 , power frequency filter capacitor 4 , standard capacitor 5 , protection res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com