Memory alloy calibrating lock and method for realizing locking and unlocking of satellite calibrating device by using same

A memory alloy and memory alloy spring technology, applied in the field of aerospace optical remote sensors, can solve the problems of reduced reliability, heavy weight, large volume, etc., and achieve the effect of less parts, light weight and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

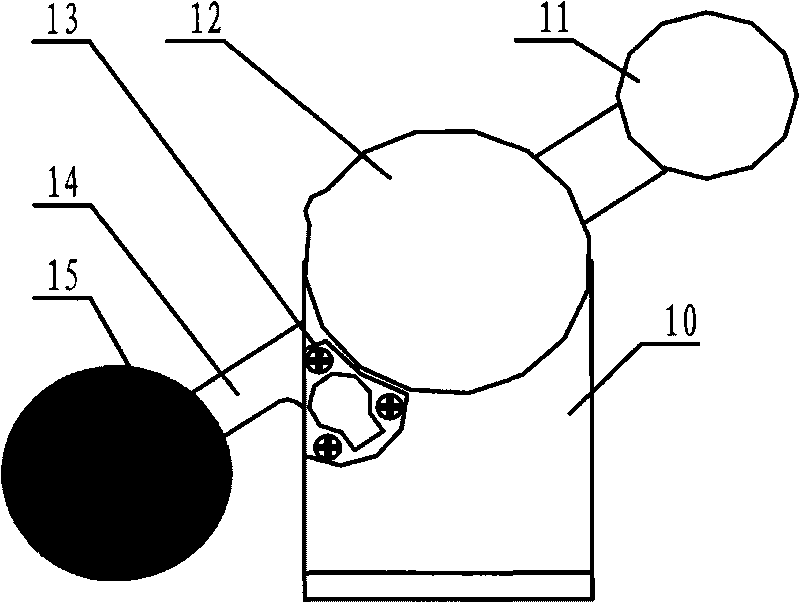

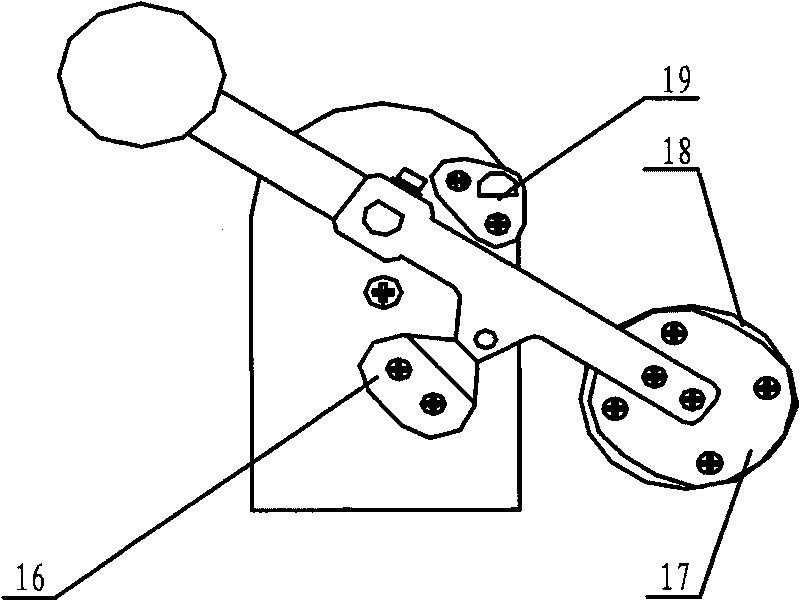

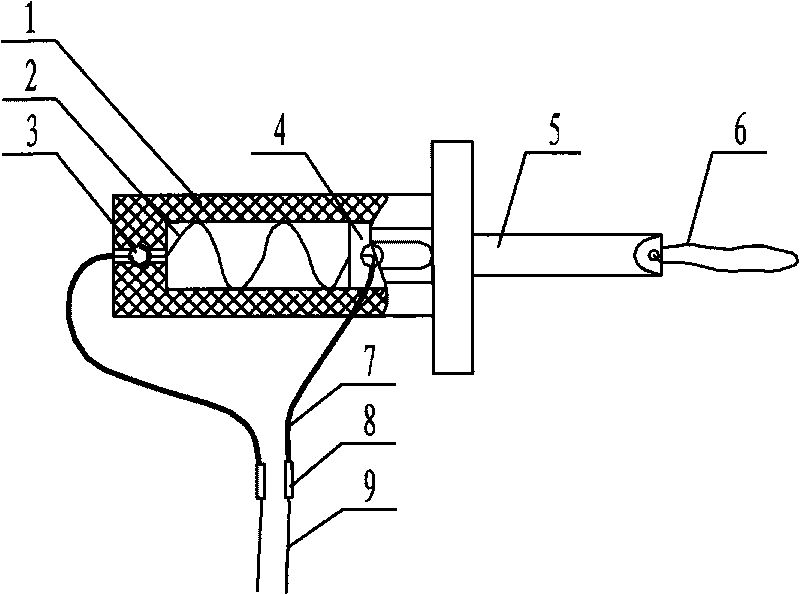

[0029] Such as image 3 As shown, the memory alloy calibration lock of the present invention includes a sleeve 1, a memory alloy spring 2, a screw 3, a limit block 4, a metal shaft 5, a soft rope 6, a heat shrinkable sleeve 7, a crimping terminal 8, and a wire 9. The memory alloy spring 2 and the limit block 4 are located inside the sleeve 1 , a part of the metal shaft 5 is inside the sleeve 1 , and a part is outside the sleeve 1 . One end of the memory alloy spring 2 is led out from the axial through hole at the bottom of the sleeve 1 and is screwed in and compressed by the screw 3 from the vertical direction. The other end of the alloy spring 2 extends into the axial through hole of the limit block 4, turns 90° and passes through the side and the side opening of the sleeve 1, and installs the screw 3 in the vertical position of the axial through hole of the limit block 4 Press and fix the memory alloy wire; add the memory alloy wire outside the sleeve 1 to the heat shrinkab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com