A method for high-precision positioning of large-scale workshops

A large-size, high-precision technology, applied in the directions of instruments, navigation, surveying and navigation, etc., can solve the problems of high-precision positioning that cannot meet the needs of large-scale workshops, serious multi-path effects, and high-precision positioning difficulties. Small size, large coverage area, simple layout effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings and specific conditions.

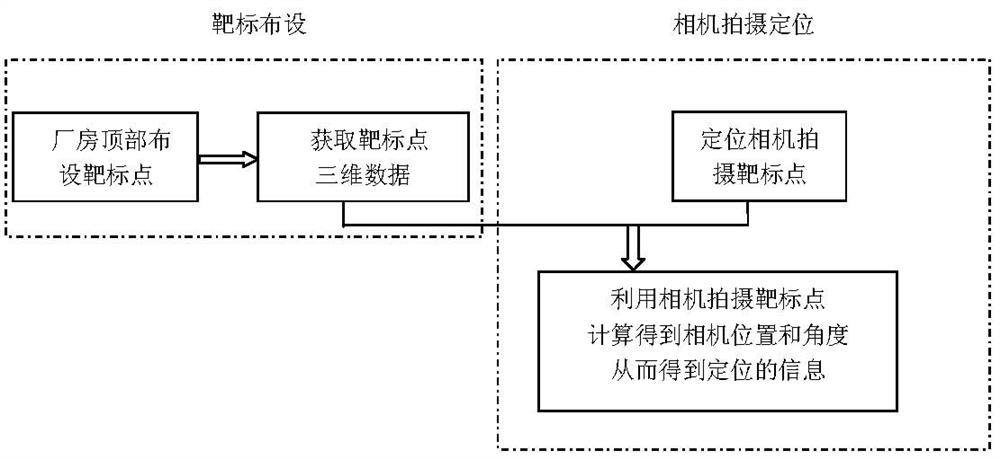

[0027] Depend on figure 1 Given, a method for high-precision positioning of a large-scale factory building in the present invention is to arrange target points on the top of the factory building, and obtain three-dimensional data of the target points, use a positioning camera to shoot the target points, use the camera to take pictures of the points, and use the computer and its software to capture the target points. The position and angle of the camera are calculated to obtain the positioning data (information) to realize high-precision positioning of large-scale workshops, which specifically includes the following steps:

[0028] 1. Arrange target points on the top of the large-scale factory building, and obtain the three-dimensional coordinate data of the target points, the method is:

[0029]1) Arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com