A rotary cloth ironing machine

An ironing machine and rotary technology, which is applied in the field of clothing manufacturing, can solve the problems of fabric wrinkles, time-consuming and laborious, and affect the quality of packaging and delivery products, so as to improve production efficiency and save time and energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Through the description of the embodiments below, the specific implementation of the present invention includes the shape, structure, mutual position and connection relationship between the various parts, the function and working principle of each part, the manufacturing process and the operation and use method of the various components involved. etc., to make further detailed descriptions to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

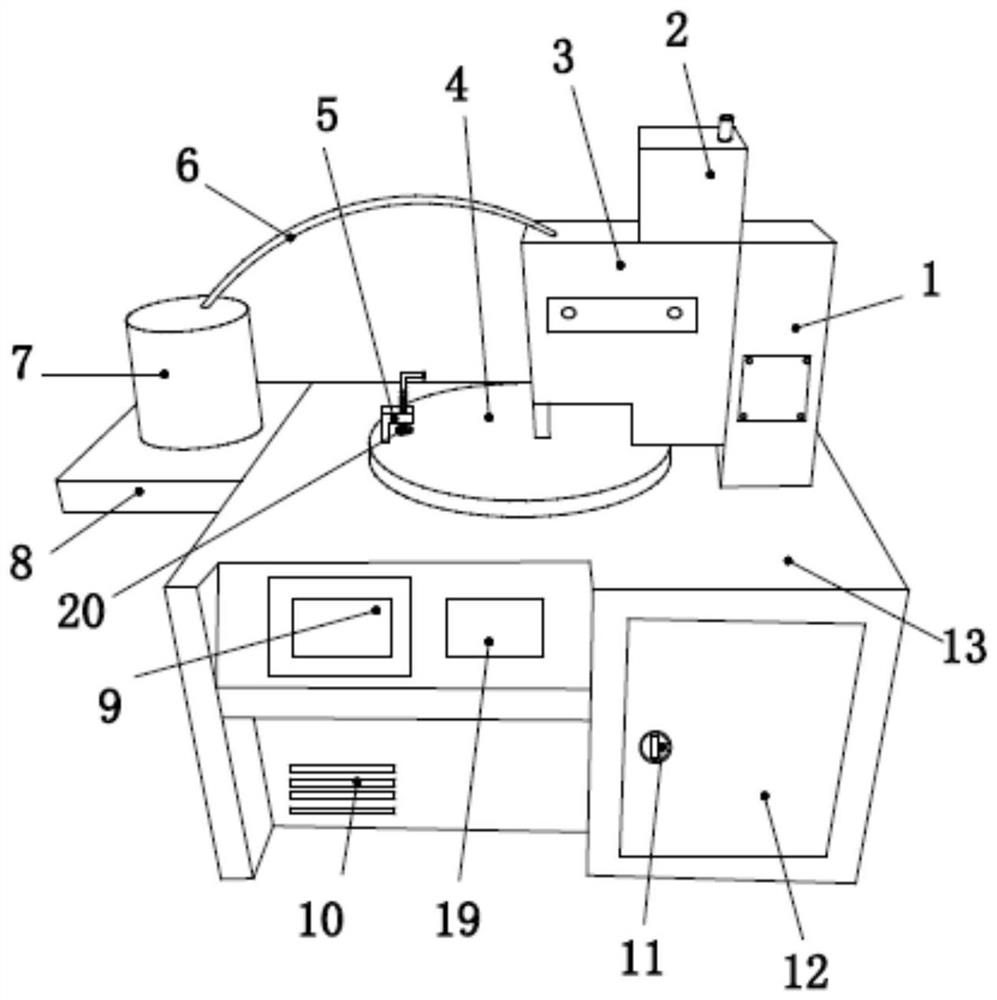

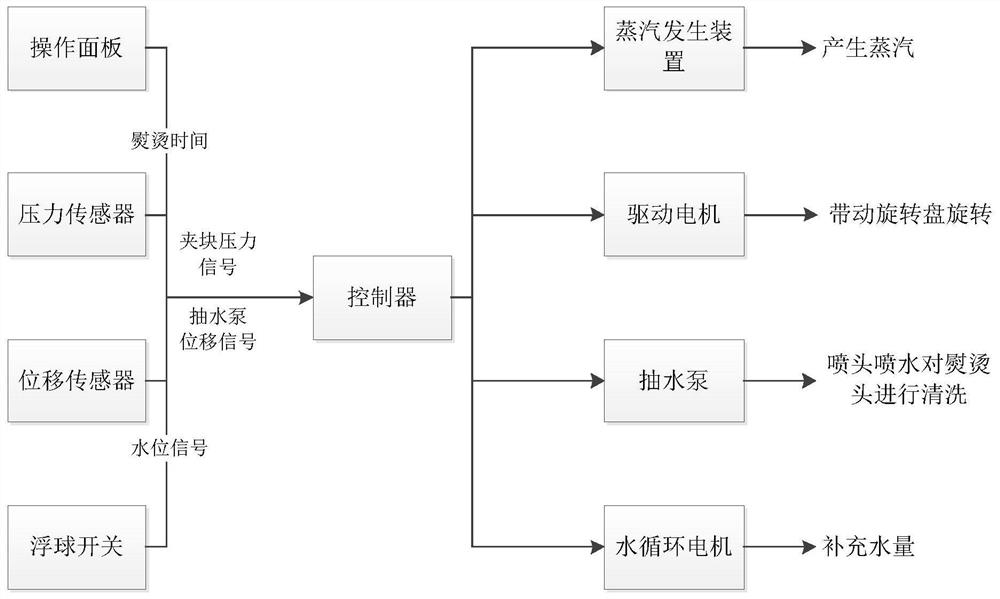

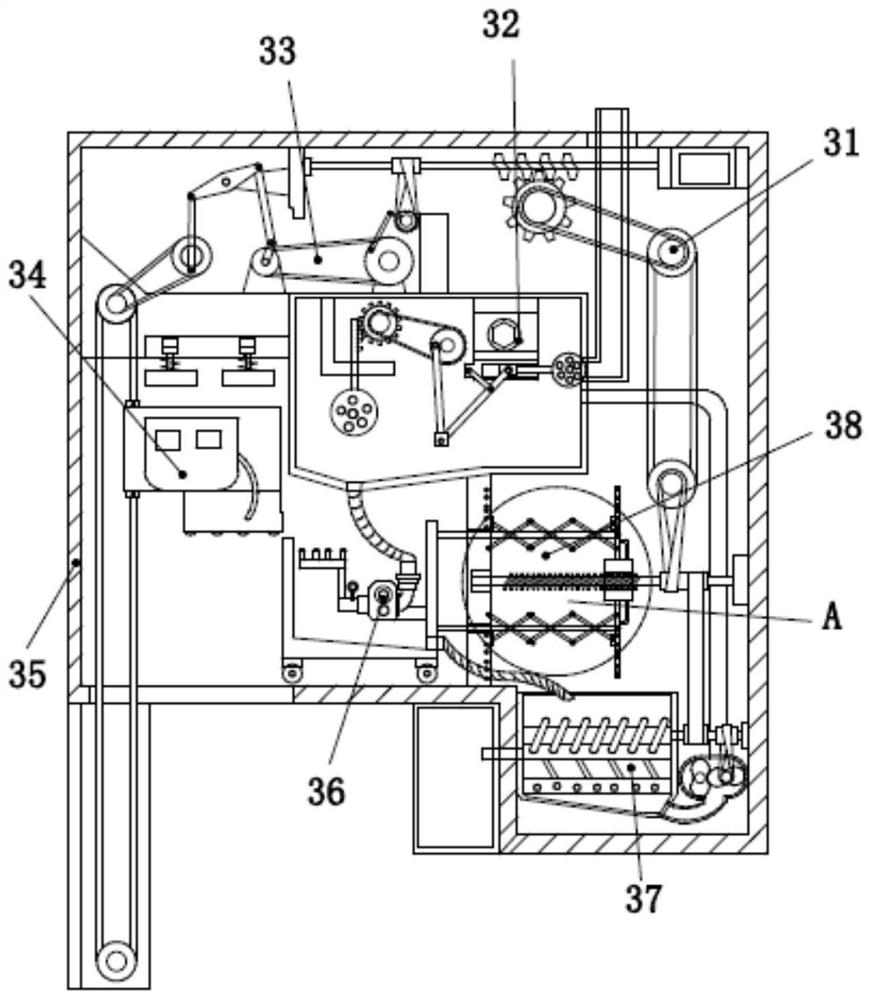

[0026] A rotary cloth ironing machine, including a fixed column 1, a water storage tank 2, an ironing and cleaning device 3, a rotating disk 4, a clamp block 5, a steam pipe 6, a steam generating device 7, a support plate 8, an operation panel 9, a control panel Device 19, vent 10, key hole 11, opening and closing door 12, device main body 13, opening and closing door 12 is hinged on the right end of device main body 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com