Bronze-gold-tooth colored zipper and manufacturing method thereof

A production method and technology of gold tooth color, which can be applied in metal material coating process, liquid chemical plating, plating of superimposed layers, etc., which can solve the problems of dark tooth color and high production cost of chain teeth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

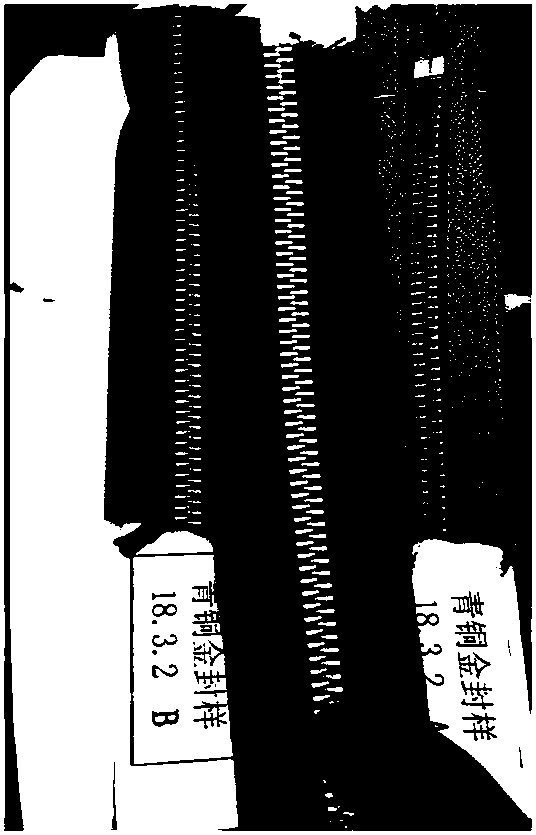

Image

Examples

Embodiment 1

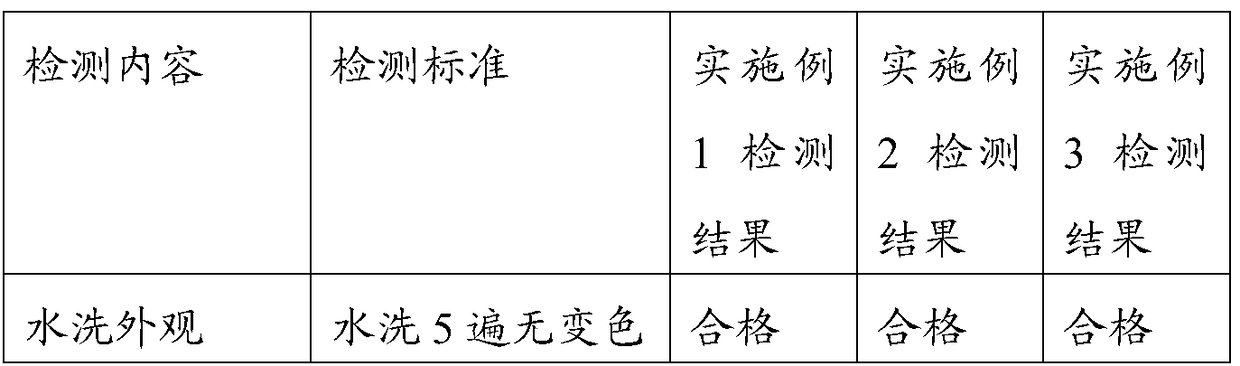

[0058] Mix 450g of selenium dioxide with 2500g of sodium persulfate, 2000g of copper nitrate, 1480g of sulfuric acid, 1420g of nitric acid, 3750g of phosphoric acid and 400g of soda ash, add 38kg of water to obtain a bronze aqueous solution, soak and turn the zipper in the mixed water for 1 minute, and then take it out Wash in water at 22°C. After cleaning, soak in: 2000 grams of stannous chloride, 6000 grams of thiourea, 700 milliliters of hydrochloric acid with a mass fraction of 38%, 200 grams of malic acid, 200 grams of fatty alcohol polyoxyethylene ether emulsifier, ethylenediaminetetraacetic acid 200 grams of disodium, 500 grams of citric acid, 800 grams of sodium hypophosphite, and 50 kg of sodium hypophosphite are mixed together and stirred evenly to form a cupronickel aqueous solution, soaked and turned for 10 seconds, then washed with water again, and then passivated for 1 minute after cleaning again; finally After washing, spin dry to get the zipper.

[0059] The p...

Embodiment 2

[0065] Mix 400g of selenium dioxide with 2250g of sodium persulfate, 1500g of copper nitrate, 1000g of sulfuric acid, 1200g of nitric acid, 3100g of phosphoric acid and 300g of soda ash, add water to obtain a 50kg bronze aqueous solution, soak and turn the zipper in the mixed water for 80s, and then take it out at 20°C Wash in water. After cleaning, soak in: 1000 grams of stannous chloride, 4750 grams of thiourea, 860 milliliters of hydrochloric acid with a mass fraction of 38%, 350 grams of malic acid, 350 grams of fatty alcohol polyoxyethylene ether emulsifier, ethylenediaminetetraacetic acid 350 grams of disodium, 750 grams of citric acid, 2500 grams of sodium hypophosphite, 50kg in total, mixed together and stirred evenly to form a cupronickel aqueous solution for 10 seconds, then washed with water again, and then passivated for 50s after cleaning again; finally cleaned After drying, the zipper is obtained.

[0066] The appearance and appearance of the slide fastener prep...

Embodiment 3

[0069] Mix 500g of selenium dioxide with 2000g of sodium persulfate, 1750g of copper nitrate, 1250g of sulfuric acid, 1000g of nitric acid, 3450g of phosphoric acid and 350g of soda ash and add water to obtain a 50kg bronze aqueous solution. °C water for washing. After cleaning, soak in: 1500 grams of stannous chloride, 2550 grams of thiourea, 450 milliliters of hydrochloric acid with a mass fraction of 38%, 500 grams of malic acid, 500 grams of fatty alcohol polyoxyethylene ether emulsifier, ethylenediaminetetraacetic acid 500 grams of disodium, 1,000 grams of citric acid, 4,500 grams of sodium hypophosphite, 50kg in total, mixed together and stirred evenly to form a cupronickel aqueous solution for 10 seconds, then washed with water again, and then passivated for 70s after cleaning again; finally cleaned After drying, the zipper is obtained.

[0070] The appearance and appearance of the slide fastener prepared by the embodiment of the present invention 3 figure 1 Consisten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com