A kind of permeable asphalt concrete and preparation method thereof

A permeable asphalt and concrete technology, applied in the field of concrete, can solve the problems of destroying the ecological balance of the urban surface, damaging the urban water balance, increasing urban noise pollution, etc., and achieving the goal of improving freeze-thaw resistance, preventing freeze-thaw damage, and good water permeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

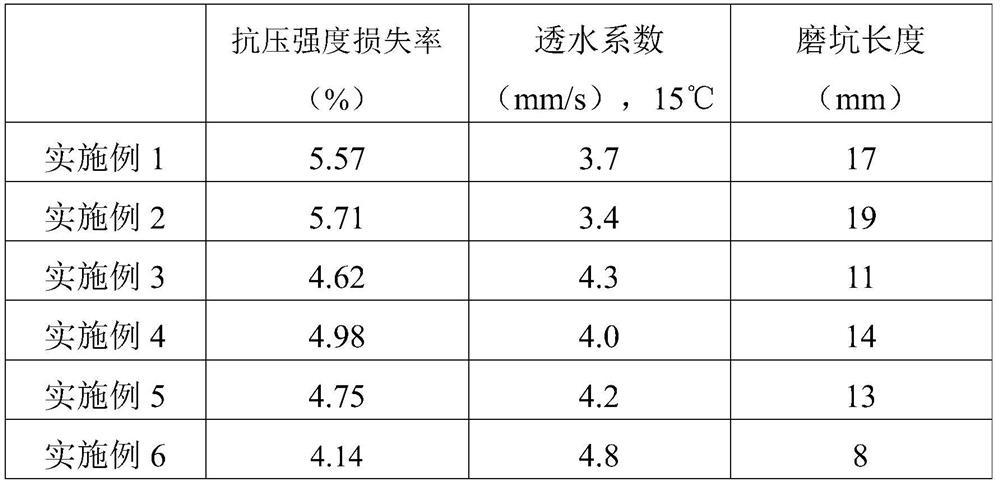

Examples

Embodiment 1

[0026] The preparation method of permeable asphalt concrete comprises the following steps:

[0027] Add 1 part by weight of water reducer to 35 parts by weight of water and stir at a speed of 300r / min for 10 minutes to obtain a water reducer solution; mix 100 parts by weight of cement, 10 parts by weight of modified asphalt, 400 parts by weight of gravel, Add one part of mineral fiber filler and 10 parts by weight of silica fume into a concrete mixer and mix evenly at a speed of 90r / min for 2 minutes, then add the water reducer solution and continue to mix at a speed of 90r / min for 5 minutes to obtain a permeable asphalt concrete.

[0028] The water reducer is a polycarboxylate water reducer.

[0029] The modified asphalt is SBR modified asphalt.

[0030] The mineral fiber filler is sepiolite fiber.

[0031] The gravel is basalt gravel with a particle size of 7mm.

[0032] Described cement is P.O 42.5 cement.

Embodiment 2

[0034] The preparation method of permeable asphalt concrete comprises the following steps:

[0035] Add 1 part by weight of water reducer to 35 parts by weight of water and stir at a speed of 300r / min for 10 minutes to obtain a water reducer solution; mix 100 parts by weight of cement, 10 parts by weight of modified asphalt, 400 parts by weight of gravel, Add one part of mineral fiber filler and 10 parts by weight of silica fume into a concrete mixer and mix evenly at a speed of 90r / min for 2 minutes, then add the water reducer solution and continue to mix at a speed of 90r / min for 5 minutes to obtain a permeable asphalt concrete.

[0036] The water reducer is a polycarboxylate water reducer.

[0037] The modified asphalt is SBR modified asphalt.

[0038] The mineral fiber filler is brucite fiber.

[0039] The gravel is basalt gravel with a particle size of 7mm.

[0040] Described cement is P.O 42.5 cement.

Embodiment 3

[0042] The preparation method of permeable asphalt concrete comprises the following steps:

[0043]Add 1 part by weight of water reducer to 35 parts by weight of water and stir at a speed of 300r / min for 10 minutes to obtain a water reducer solution; mix 100 parts by weight of cement, 10 parts by weight of modified asphalt, 400 parts by weight of gravel, Add one part of mineral fiber filler and 10 parts by weight of silica fume into a concrete mixer and mix evenly at a speed of 90r / min for 2 minutes, then add the water reducer solution and continue to mix at a speed of 90r / min for 5 minutes to obtain a permeable asphalt concrete.

[0044] The water reducer is a polycarboxylate water reducer.

[0045] The modified asphalt is SBR modified asphalt.

[0046] The mineral fiber filler is functional sepiolite fiber.

[0047] The preparation method of the functionalized sepiolite fiber is as follows: add 150g polyvinyl alcohol and 50g xanthan gum into 1500g water and stir at a speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com