Method for improving dewatering property of sludge by biological conditioning

A sludge dewatering and sludge technology, applied in the field of environmental engineering, can solve problems such as environmental pollution, and achieve the effects of avoiding environmental risks, significant dehydration effect, and obvious volume reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

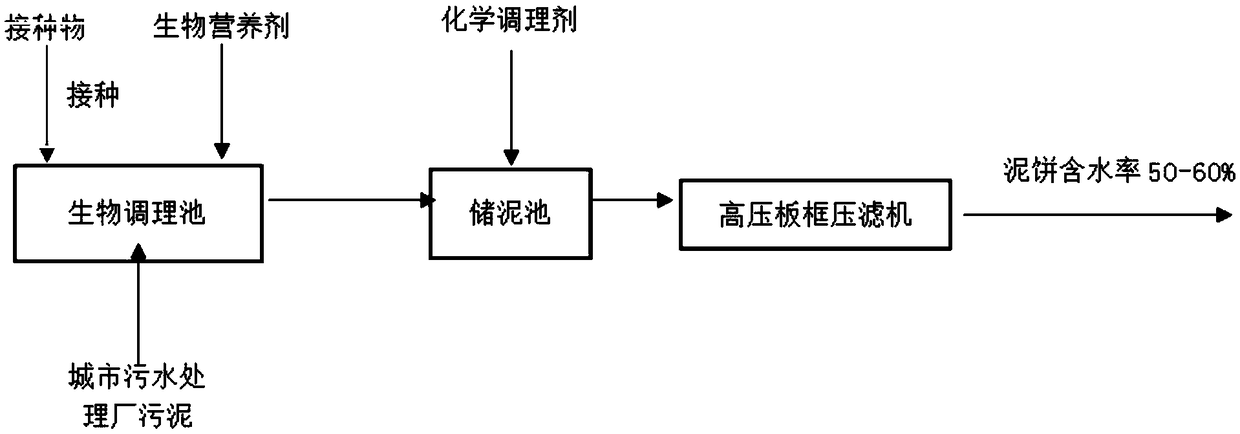

Image

Examples

Embodiment 1

[0027] Cultivate bacillus pumilus, pseudomonasdenitrificans, pseudomonas fluorescens, aquaspirillumgracile, and aquaspirillumdispa according to conventional methods. The total number of cells is 100%, and the number of cells is 15%, 20%, 25%, 30%, and 10% respectively. Mix them and add them to the complex biological culture medium in a sterile environment for multiplication and cultivation. Until the total number of bacteria in the compound bacterial solution reaches 1×10 9 Above cfu / ml, it is a composite biological bacterial liquid.

[0028] Take fresh sludge from a sewage treatment plant in Shanghai, and inoculate the composite biological bacteria into the sludge according to the volume ratio (v / v) of the composite biological bacteria liquid to the sludge. Into the biological fermentation tank, stirring and culturing at room temperature until the total number of complex biological bacteria cells reaches 10 7 Pieces / mL, the required inoculum is obtained.

[0029] Take sludge (slu...

Embodiment 2

[0032] Cultivate bacillus pumilus, seudomonas denitrificans, pseudomonas fluorescens, aquaspirillum gracile and aquaspirillumdispa according to conventional methods to The total number of bacteria is 100%, and the number of bacteria is 20%, 20%, 20%, 25%, and 15% respectively. Mix them and add them to the composite biological culture medium under aseptic environment for multiplication and cultivation. , Until the total number of bacteria in the compound bacterial solution reaches 1×10 9 Above cfu / ml, it is a composite biological bacterial liquid.

[0033] Take the fresh sludge from the municipal sewage treatment plant, inoculate the composite biological bacteria into the sludge according to the volume ratio (v / v) of the composite biological bacteria liquid to the sludge, and place the sludge inoculated with the composite biological bacteria into the sludge. In the biological fermentation tank, stirring and culturing at room temperature until the total number of complex biological...

Embodiment 3

[0037] Cultivate bacillus pumilus, pseudomonasdenitrificans, pseudomonas fluorescens, aquaspirillumgracile, and aquaspirillumdispa according to conventional methods. The total number of cells is 100%, and the number of cells is 20%, 15%, 25%, 25%, and 15% respectively. Mix them and add them to the complex biological culture medium in a sterile environment for multiplication and cultivation. Until the total number of bacteria in the compound bacterial solution reaches 1×10 9 Above cfu / ml, it is a composite biological bacterial liquid.

[0038] Take the fresh sludge from the municipal sewage treatment plant, inoculate the composite biological bacteria into the sludge according to the volume ratio (v / v) of the composite biological bacteria liquid to the sludge, and place the sludge inoculated with the composite biological bacteria into the sludge. In the biological fermentation tank, stirring and culturing at room temperature until the total number of complex biological cells reache...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com