Environment-friendly white carbon black preparation method

A white carbon black and environmental protection technology, applied in the field of white carbon black technology, can solve the problems of low white carbon black yield, high waste water treatment cost, and difficult treatment, so as to overcome uneven heating, improve aging process, and enhance BET. The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

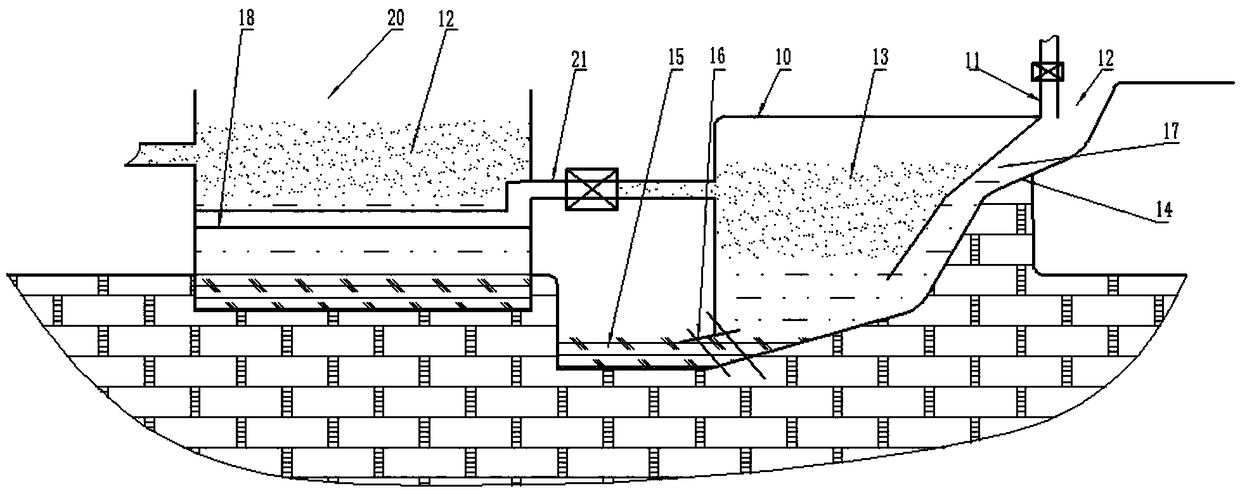

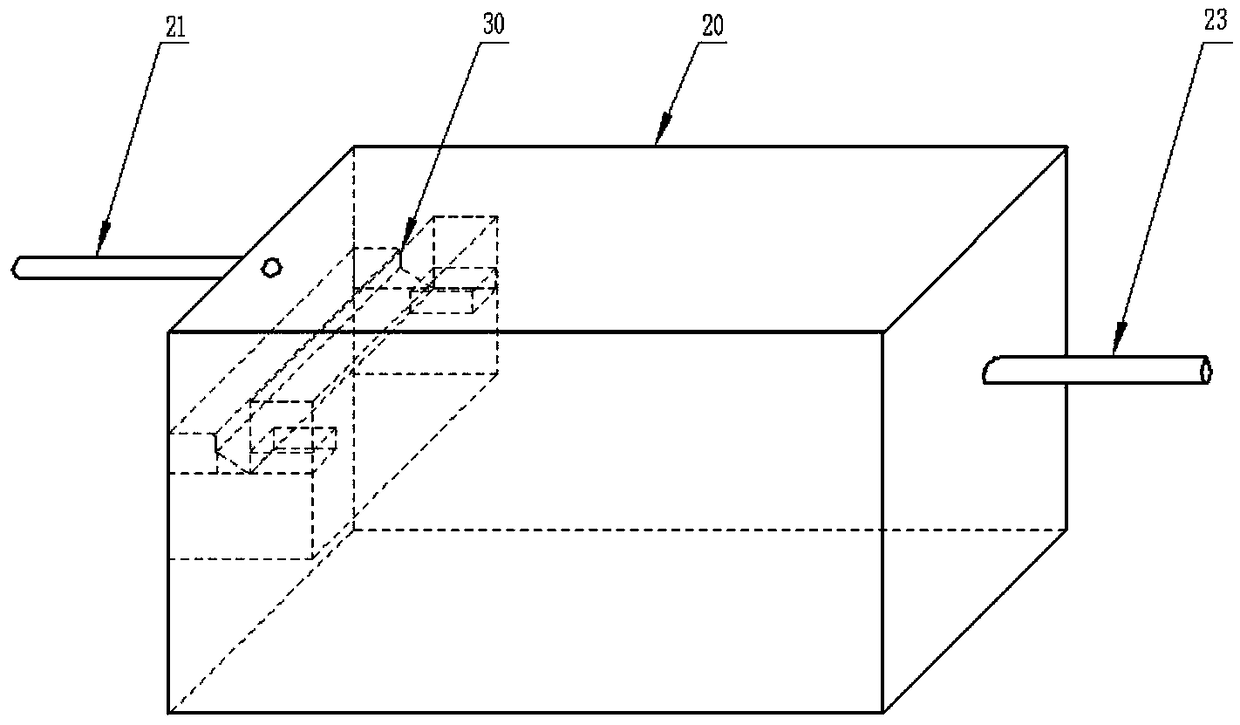

[0051] A preparation method of environment-friendly white carbon black, comprising the following steps:

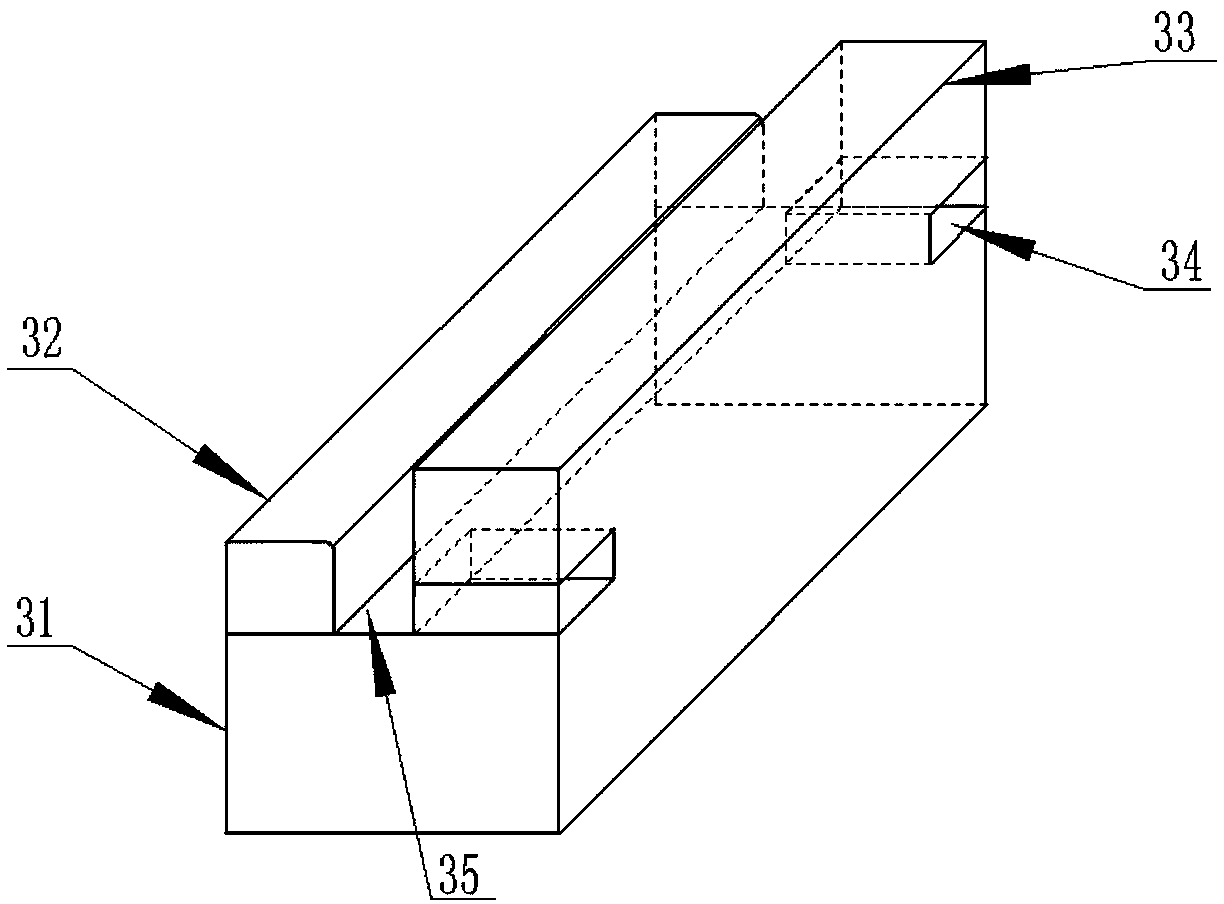

[0052] S1: Add solid sodium silicate to the dissolving device, add water and seal the dissolving device, feed steam until the steam pressure in the dissolving device reaches 120 cm mercury column, and stop when all the sodium silicate is dissolved, forming a specific gravity of 1.37 g / cm 3 dilute sodium silicate solution, and put the above dilute sodium silicate solution into the reactor;

[0053] S2: Slowly transport 98% concentrated sulfuric acid through the pipeline to the dilution tank for dilution to form a specific gravity of 1.27g / cm 3 dilute sulfuric acid, the dilute sulfuric acid formed above 3 / h transported to the reaction kettle, and mixed and stirred when the reaction temperature was controlled at 31°C until the pH of the solution in the reaction kettle reached 7, left to stand for 2 hours to age and generate crystal seeds, and then stirred to form a mixed s...

Embodiment 2

[0059] The content of this embodiment is basically the same as that of Example 1, and the similarities will not be repeated. The difference is that in step S1, solid sodium silicate is added to the dissolving device, water is added and the dissolving device is sealed, and the Steam until the steam pressure in the dissolving device reaches 125cm Hg and stop. After all the sodium silicate is dissolved, the specific gravity is 1.37g / cm 3 dilute sodium silicate solution, and put the dilute sodium silicate solution into the reaction kettle.

Embodiment 3

[0061] The content of this embodiment is basically the same as that of Example 1, and the similarities will not be repeated. The difference is that in step S1, solid sodium silicate is added to the dissolving device, water is added and the dissolving device is sealed, and the Steam until the steam pressure in the dissolving device reaches 150cm Hg and stop, after all the sodium silicate is dissolved, the specific gravity is 1.37g / cm 3 dilute sodium silicate solution, and put the dilute sodium silicate solution into the reaction kettle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com