Simple assembling and disassembling device for vertical straight arm flange connecting equipment

A connection equipment, vertical technology, applied in the field of disassembly and assembly devices, can solve the problems of high cost, time-consuming and laborious disassembly and assembly, inconvenient and other problems, and achieve the effect of low cost, high efficiency and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

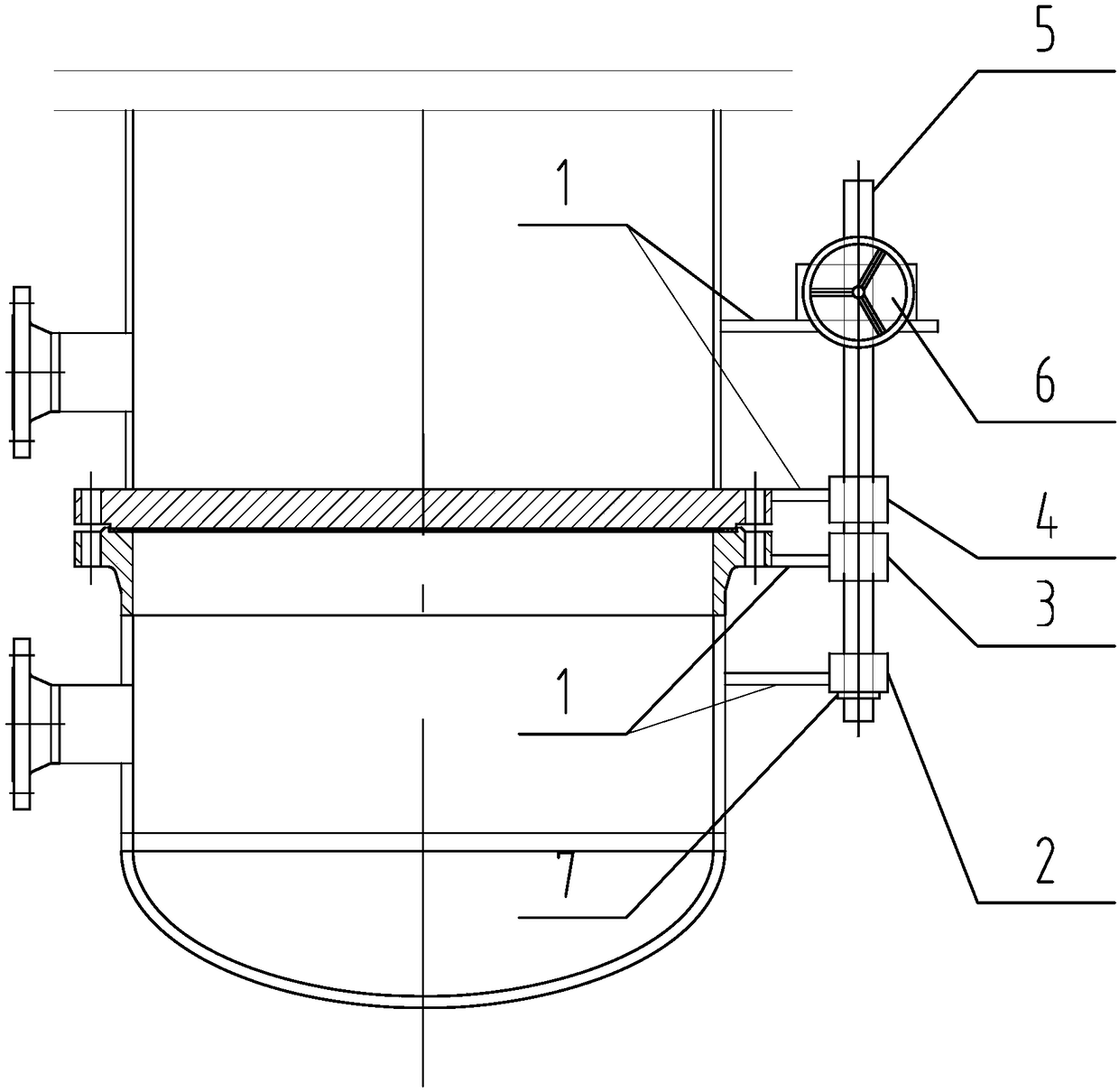

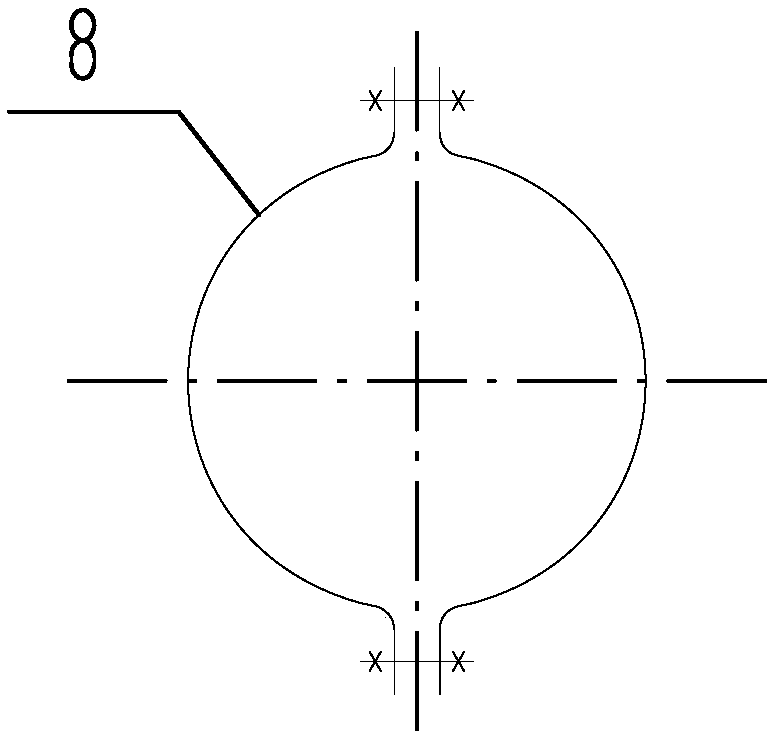

[0020] Such as figure 1 As shown: the flange connection equipment is a new vertical heat exchanger, which includes two parts, the shell side and the tube box. The tube box is on the bottom, and the shell side is on the top. There are the first bushing 4, the second bushing 3 and the first bushing 2, the turbine screw lifter 6 is welded to the shell shell through the connecting plate 1, and the first bushing 4 is welded to the tube plate through the connecting plate 1 On the flange, the second bushing 3 is welded on the pipe box flange through the connecting plate 1, the first bushing 2 is welded on the pipe box cylinder through the connecting plate 1, and the first bushing 4 is provided with a lock nut 7 .

[0021] The new vertical heat exchanger of this embodiment is disassembled and then reassembled for on-site inspection and maintenance as follows:

[0022] 1. The present invention is welded to the shell of the heat exchanger as shown in the figure.

[0023] ② Tighten th...

Embodiment 2

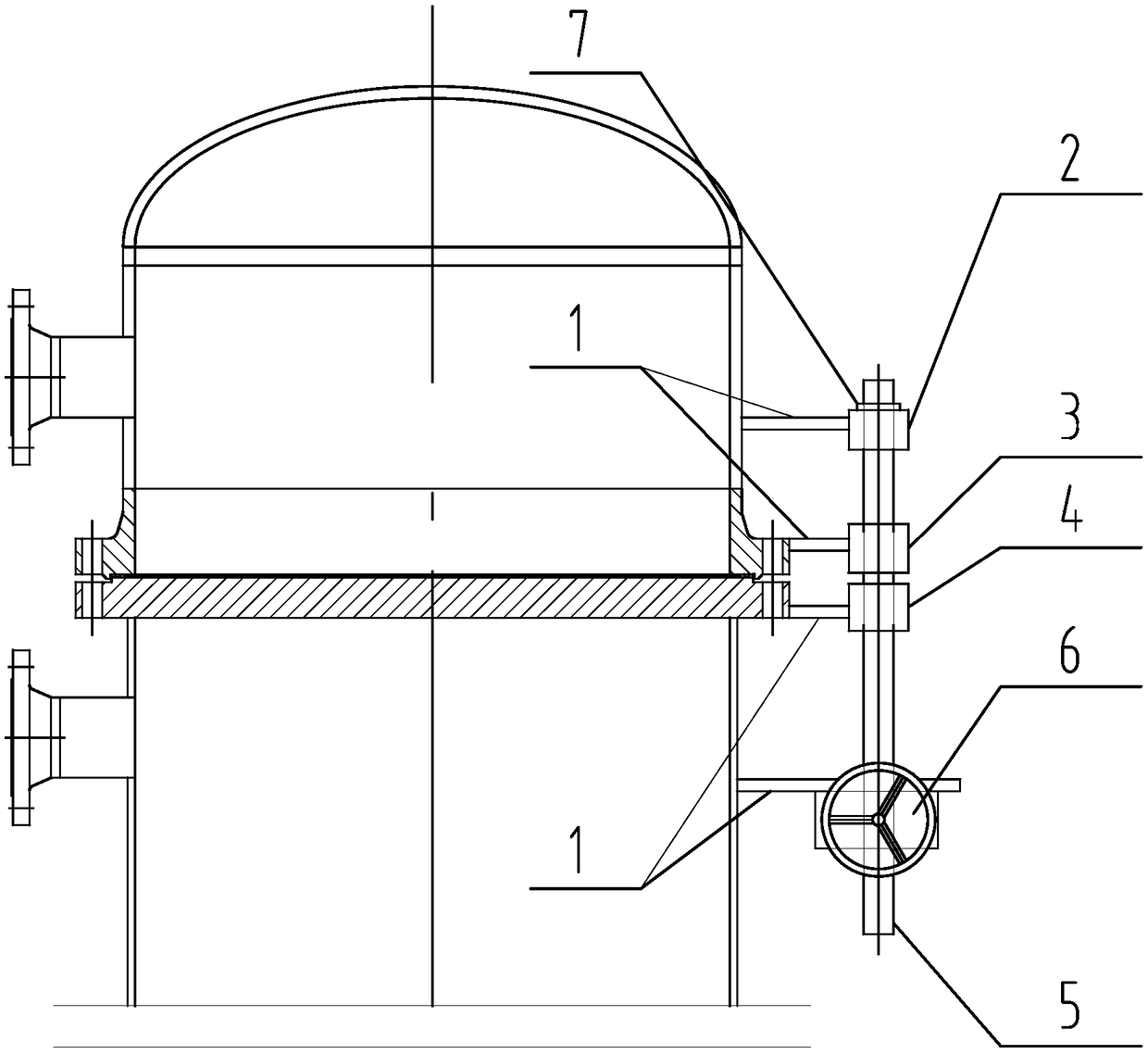

[0029] The flange connection equipment is a new vertical heat exchanger, which includes two parts, the shell side and the tube box, the tube box is on the top, and the shell side is on the bottom.

[0030] The new vertical heat exchanger of this embodiment is dismantled and then reassembled for on-site inspection and maintenance, the process is the same as that of Embodiment 1, except that the handwheel is turned during dismantling to make the pipe box rise slightly to break away from the flange connection stop.

Embodiment 3

[0032] The flange connection equipment is an old vertical heat exchanger, which allows welding, and the others are the same as in Embodiment 1.

[0033] The on-site maintenance of this embodiment is completely the same as that of Embodiment 1 when it is first dismantled and then reassembled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com