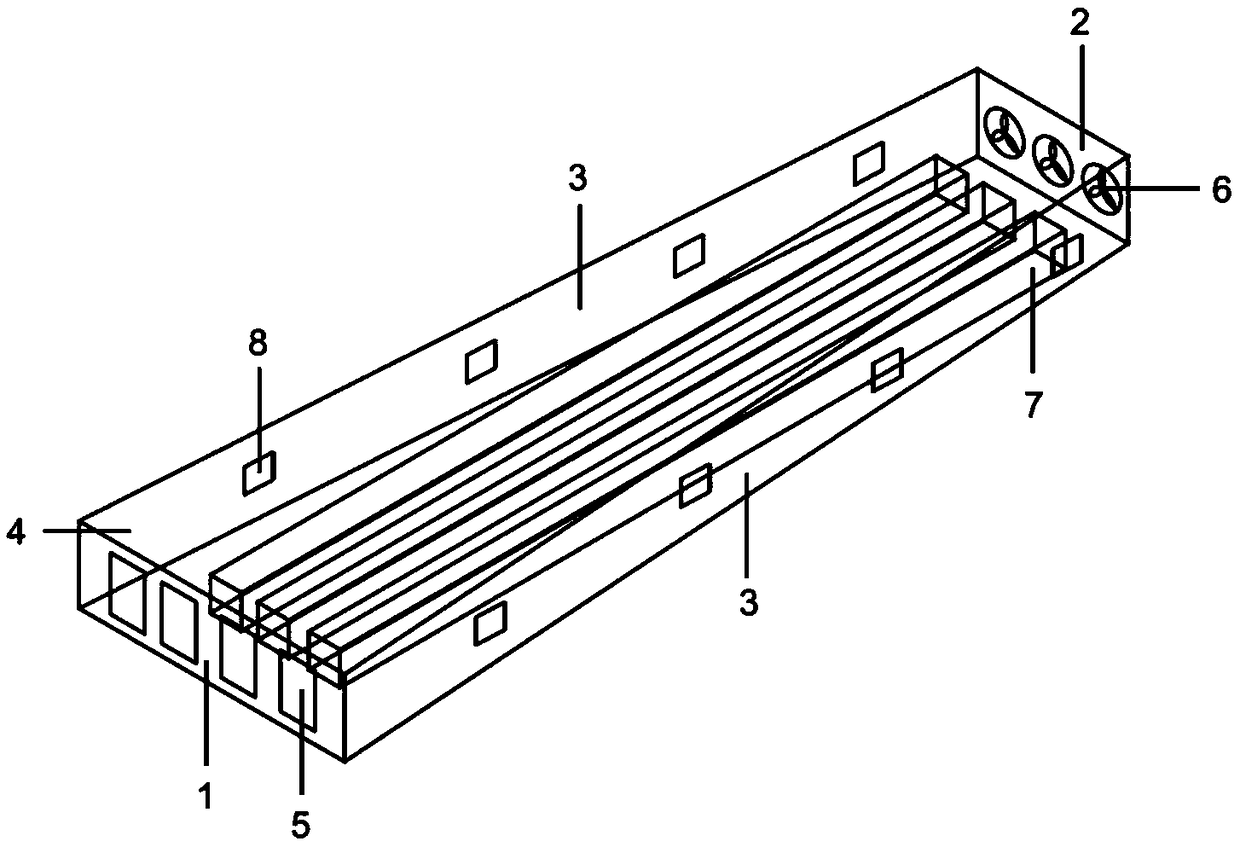

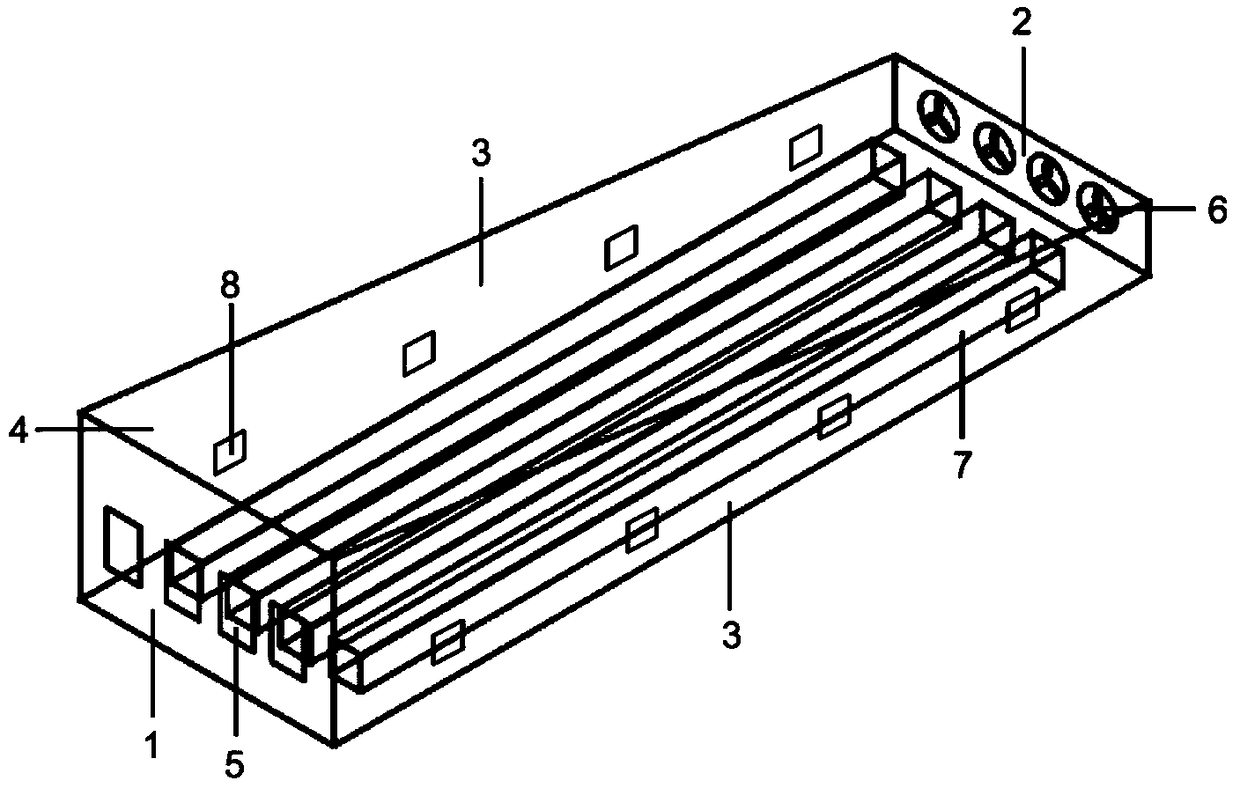

Poultry house with variable cross sections and capable of uniform heat exchanging, poultry house group, poultry house design and reconstruction method

A technology of variable cross-section and poultry house, which is applied in animal houses, poultry cages or houses, and poultry industry, etc., can solve the problem of large energy consumption in temperature control of poultry houses, difficult transformation of poultry houses, and uneven heat exchange of birds. and other problems, so as to avoid insufficient heat exchange or excessive heat exchange, the transformation method is simple and easy, and the floor space is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0133] The technical solutions of the present disclosure are further illustrated below through examples. This example is illustrative rather than restrictive, and the scope of the present disclosure is not limited to the solution given in the calculation example, and those skilled in the art can select appropriate parameters according to the description of the present disclosure and actual needs.

[0134] It should be noted that the embodiments provided in the present disclosure are intended to take a chicken coop as an example to illustrate the technical solution of the present disclosure. The parameters mentioned in the embodiments are only examples to help explain the description, and do not constitute limitations to the present disclosure. Those skilled in the art can, on the basis of understanding the principles explained in the examples, determine the basic parameters according to the needs of actual work, and then design variable-section poultry houses according to the ...

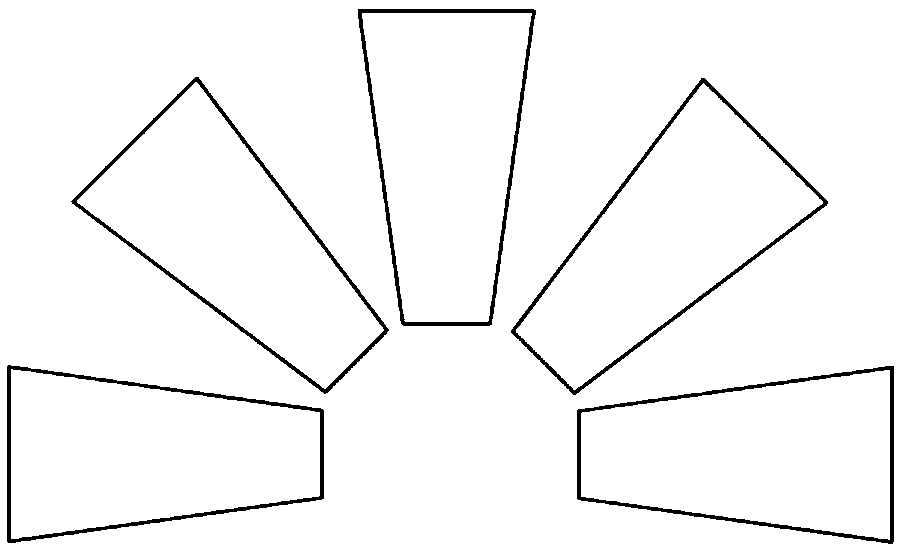

Embodiment 2

[0144] Aiming at the problem of uneven heat transfer in various parts of the chicken house in Comparative Example 1, with reference to the basic conditions of Comparative Example 1, using the principles and methods provided by the present disclosure, and following a process similar to that of Example 1, the ventilation system of Example 2 was designed. Heat exchange scheme.

[0145] In Embodiment 2, the ceiling of the chicken house is 3.5m high and parallel to the ground. The chicken coop is a chicken coop with a variable cross-section, and its top view shape is trapezoidal. The two sides parallel to the trapezoid are gables. The formula provided is calculated as 37m; the other two sides of the chicken house are side walls, and the height of the trapezoid is 64m (the length of the long axis of the chicken house in Comparative Example 1 is the same). There are ventilation windows on the front gable wall, and the installation area of the ventilation windows is 35m2 2 The wet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com