Biomass gasification burner

A burner and biomass technology, applied in combustion methods, combustion equipment, solid fuel combustion, etc., can solve the problems of low gasification rate of biomass fuel, unreasonable design of oxygen supply equipment, large smoke and dust emissions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

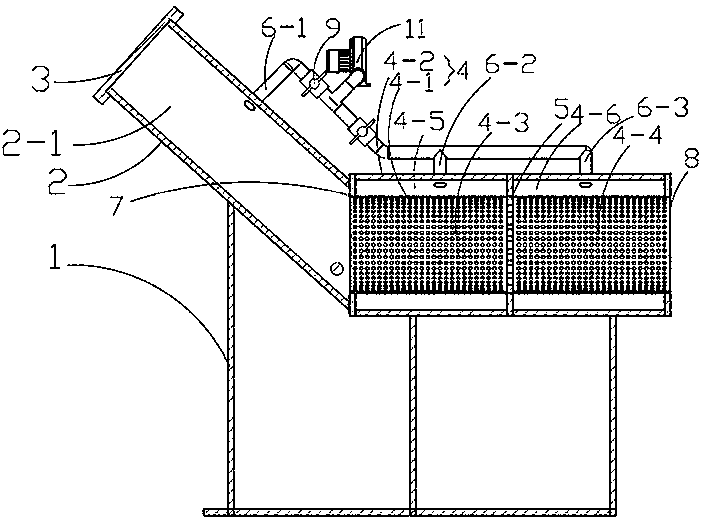

[0038] as attached figure 1 To attach figure 2 As shown, a biomass gasification burner includes a bracket 1, a primary combustion tube 2 is fixedly installed on the top of the bracket 1, the interior of the primary combustion tube 2 is a combustion chamber 2-1, and the nozzle at one end of the primary combustion tube 2 is fuel Inlet 3, the other end is connected with a secondary combustion tube 4; the secondary combustion tube 4 includes a secondary combustion inner tube 4-1 and a secondary combustion outer tube 4-2 coaxially arranged with the secondary combustion inner tube 4-1 , the cracking disc 5 arranged in the secondary combustion tube 4 divides the secondary combustion inner tube 4-1 into a gasification chamber 4-3 and a fire chamber 4-4, and the gasification chamber 4-3 and the fire chamber 4-4 They are communicated through the fire hole on the cracking disc 5; the mouth of the secondary combustion tube 4 outer end is also covered with a dust filter 8, the secondary ...

Embodiment 2

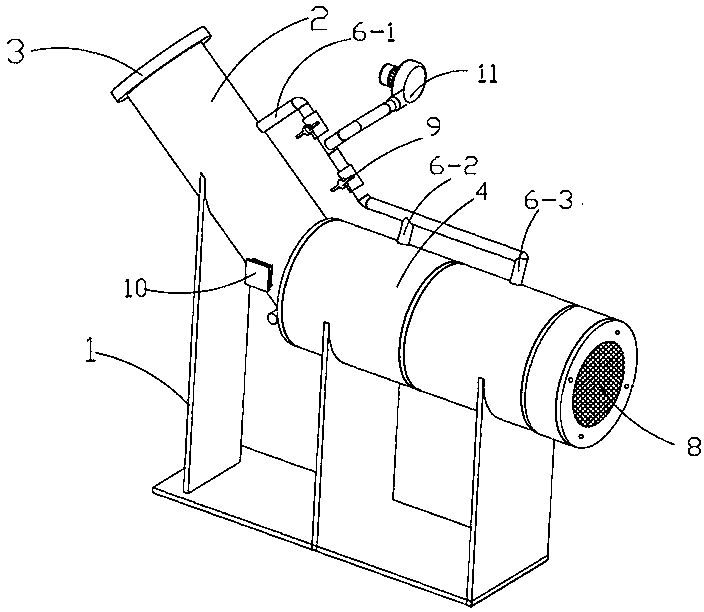

[0043] as attached image 3 To attach Figure 4 As shown, a biomass gasification burner includes a bracket 1, a primary combustion tube 2 is fixedly installed on the top of the bracket, the primary combustion tube 2 is a combustion chamber 2-1, and the nozzle at one end of the primary combustion tube 2 is a fuel inlet 3 , the other end communicates with a secondary combustion tube 4; the secondary combustion tube 4 includes a secondary combustion inner tube 4-1 and a secondary combustion outer tube 4-2 coaxially arranged with the secondary combustion inner tube 4-1, the secondary combustion tube 4 The cracking disc 5 that is set in the secondary combustion tube 4 divides the secondary combustion inner tube 4-1 into a gasification chamber and a fire chamber 4-4, and the gasification chamber and the fire chamber 4-4 pass through the cracking disc 5. The fire hole is connected; the outer end of the secondary combustion pipe 4 is also covered with a dust filter 8.

[0044] The s...

Embodiment 3

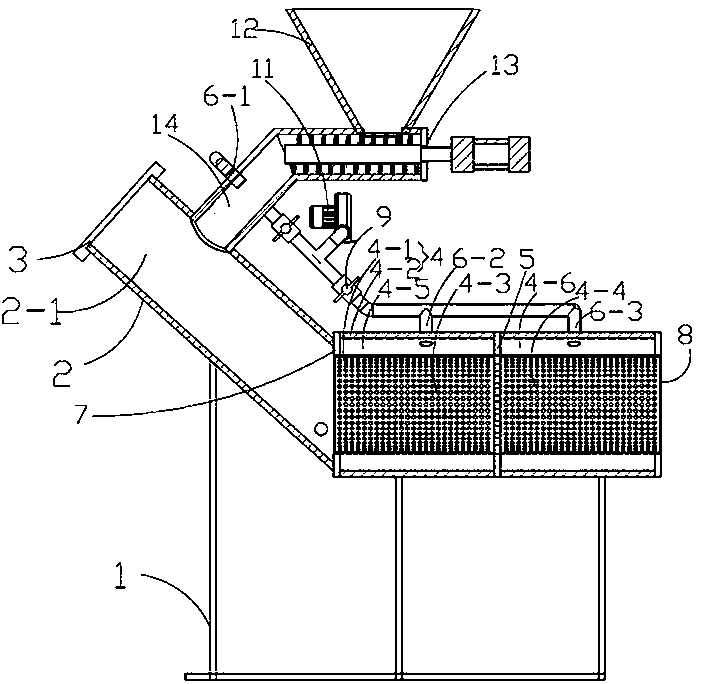

[0049] as attached Figure 5 To attach Figure 8 As shown, a biomass gasification burner includes a bracket 1, a primary combustion tube 2 is fixedly installed on the top of the bracket 1, the primary combustion tube 2 is a combustion chamber, the nozzle at one end of the primary combustion tube 2 is a fuel inlet 3, and the other One end communicates with a secondary combustion tube 4; the secondary combustion tube 4 includes a secondary combustion inner tube 4-1 and a secondary combustion outer tube 4-2 coaxially arranged with the secondary combustion inner tube 4-1. The cracking disc 5 arranged in the tube 4 divides the secondary combustion inner tube 4-1 into a gasification chamber 4-3 and a fire injection chamber 4-4, and the gasification chamber 4-3 and the fire injection chamber 4-4 are separated by cracking The fire holes on the disc 5 are connected; the outer end of the secondary combustion tube 4 is also covered with a dust filter 8 .

[0050] The secondary combusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com