Distance light and short-distance light linked dimming mechanism

A dimming motor and dipped beam technology, which is applied in the direction of light source fixing, lighting and heating equipment, transportation and packaging, etc., can solve the problems of small space and difficulty in arranging linkage adjustment mechanisms, etc., achieve compact structure, reduce costs, and realize dimming The effect of the function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

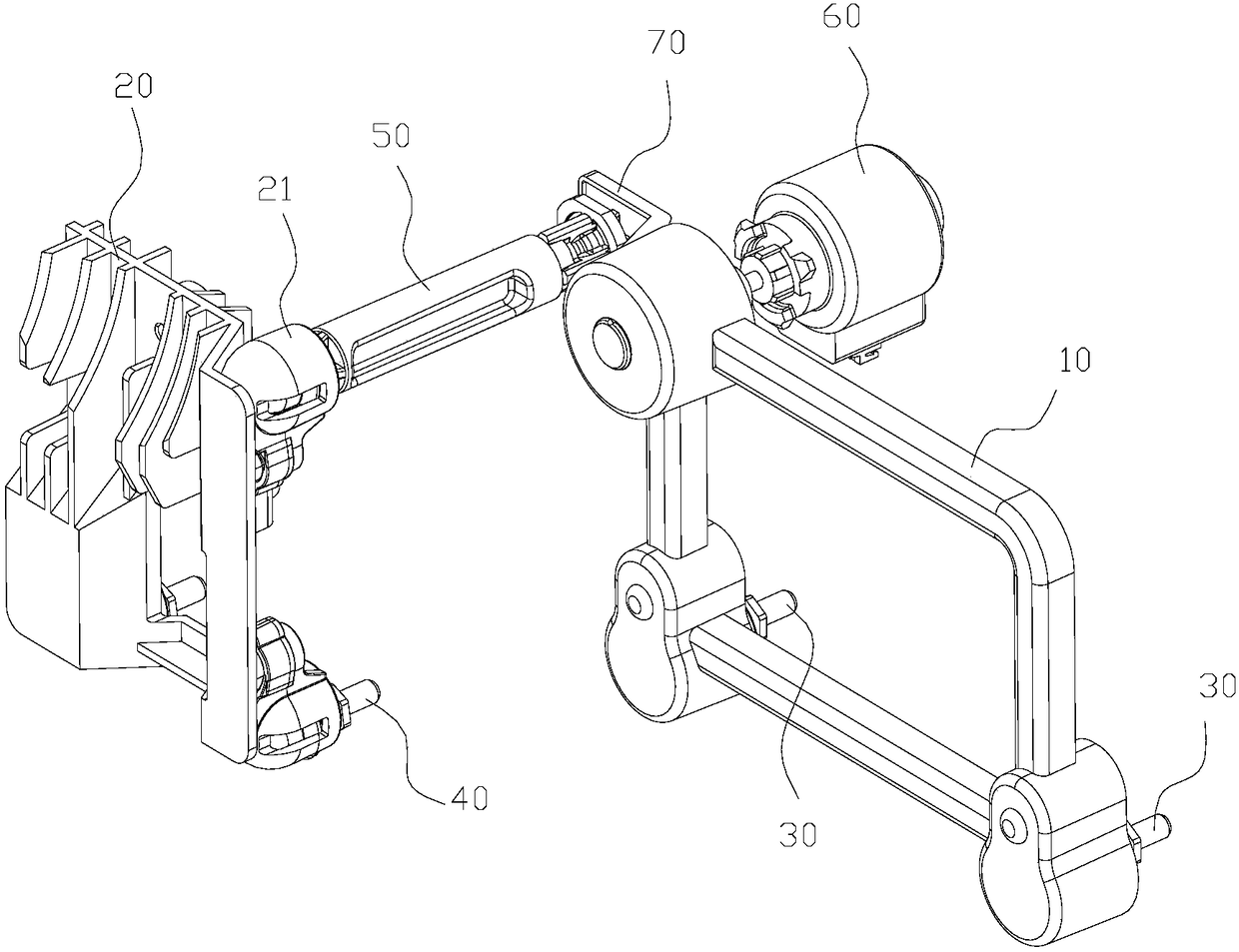

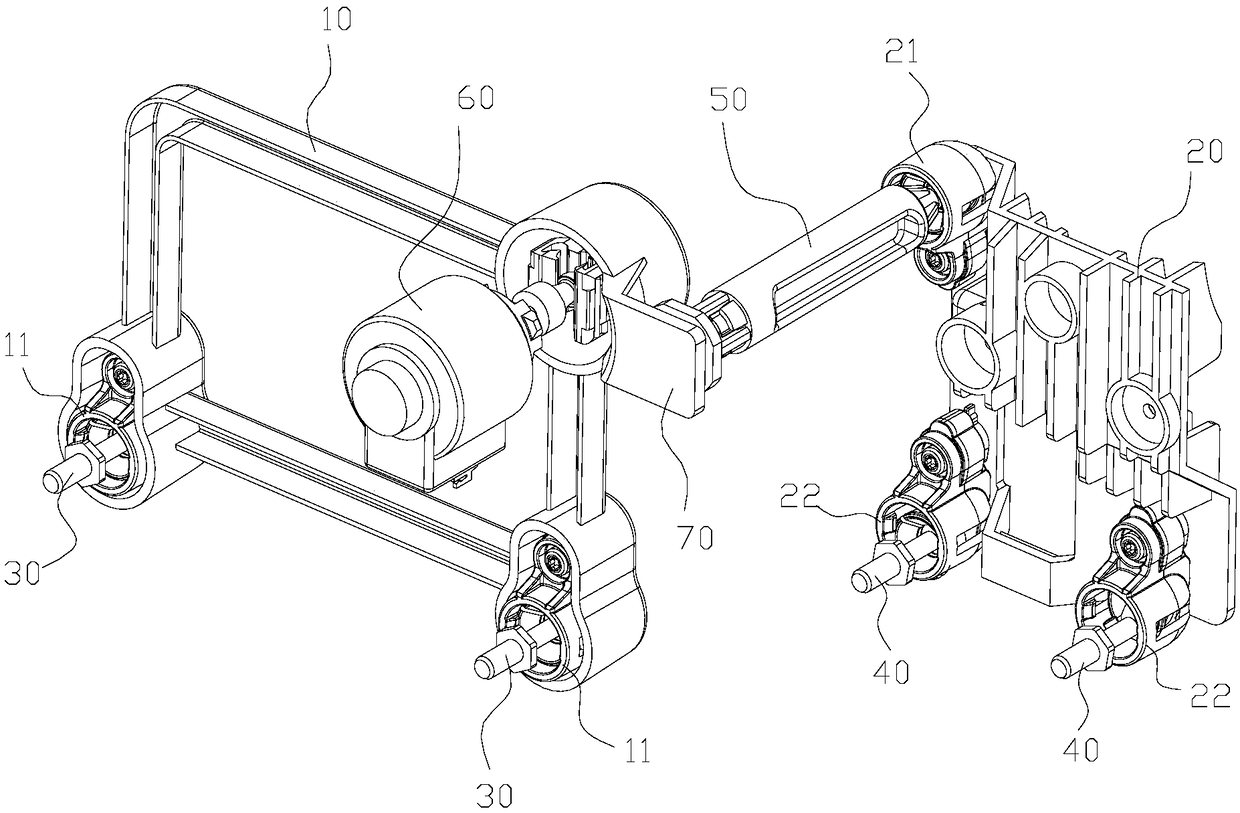

[0017] Combine below Figure 1-4 , to further describe the present invention.

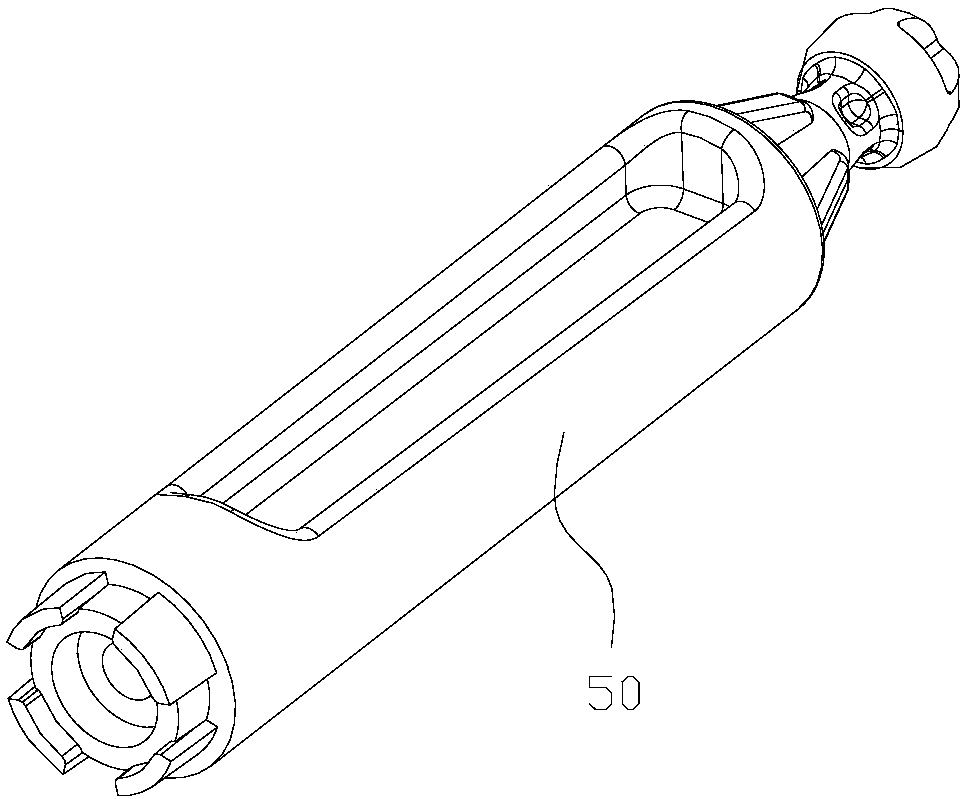

[0018] A far and low beam linkage dimming mechanism, comprising a low beam bracket 10 and a high beam bracket 20, wherein one side of the low beam bracket 10 is rotatably matched with the first dimming screw 30, and one side of the high beam bracket 20 is matched with the second dimming screw 30. The light screw 40 is rotated and matched, and the low beam bracket 10 and the high beam bracket 20 are connected by a linkage rod 50, and the linkage rod 50 is perpendicular to the low beam bracket 10 and the high beam bracket 20 at the same time, and the extension and contraction of the low beam bracket 10 and the dimming motor 60 The rods are vertically connected, and the dimming motor 60 can simultaneously drive the low beam bracket 10 to rotate around the side where the first dimming screw 30 is located, drive the high beam bracket 20 to rotate around the side where the second dimming screw 40 is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com