Carding machine

A carding machine and pre-carding technology, which is applied in the field of carding machines, can solve the problems of inability to improve efficiency and inability to take out fiber webs, and achieve the effect of simplifying installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

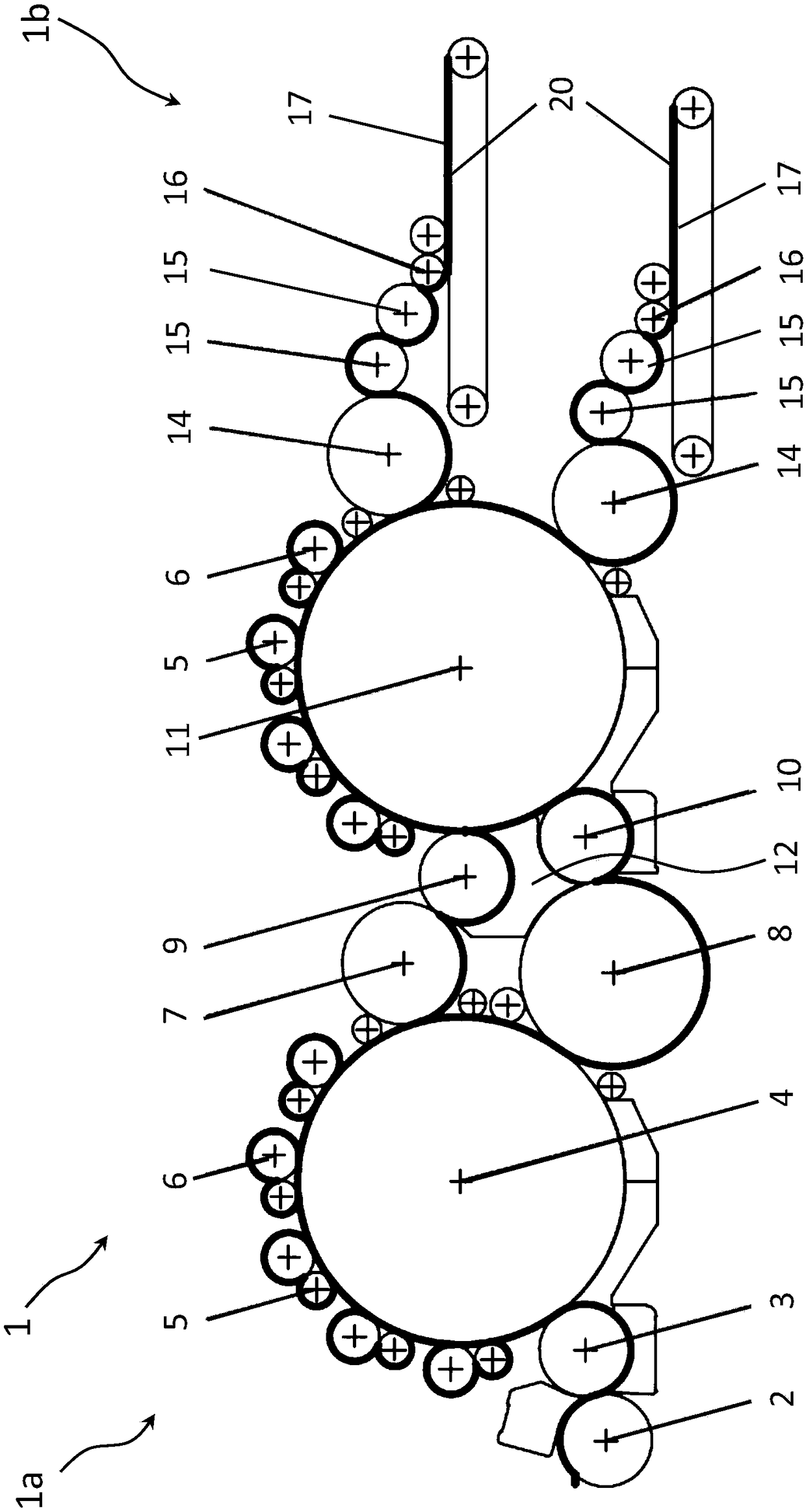

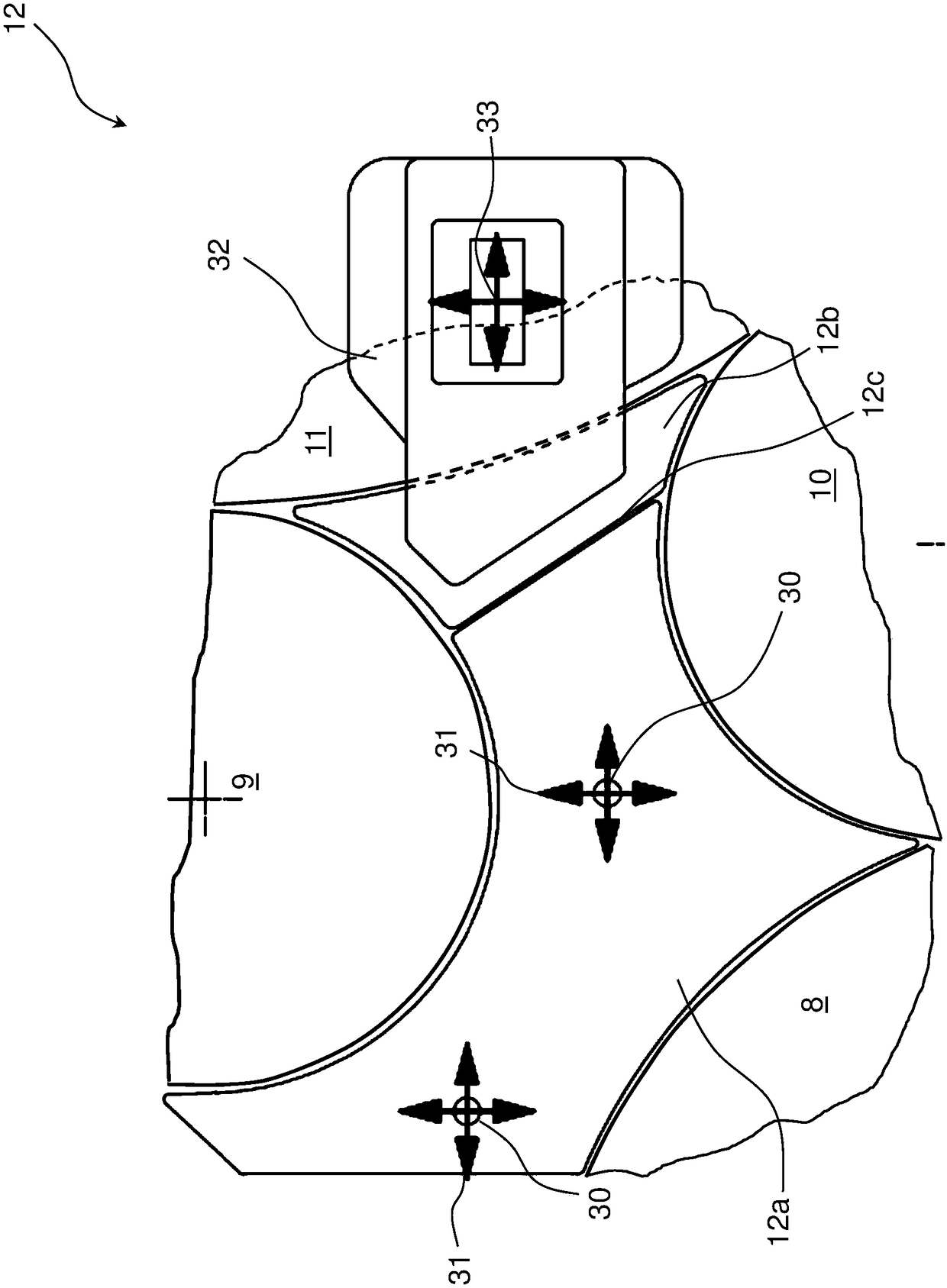

[0024] figure 1 A card 1 according to the invention is shown, which is designed as a card with a double transfer mechanism and has an inlet side 1 a for fiber fluff and one or more outlet sides 1 b for a fiber web 20 . In front of the feed side 1a of the carding machine 1 is installed a feeder not shown, such as a vibrating slide feeder, by means of which the fiber fluff is placed on a conveyor not shown. bring. Instead of a vibrating slide feeder, the card 1 can also be equipped with a card feeder with an integrated fiber material thickness gauge, in which card feeder the weight is determined by means of the fiber material thickness gauge, Alternatively, the fiber fluff is fed to the carding machine 1 by means of a direct feed.

[0025] In the card 1, the fiber fluff is conveyed to the device on the infeed side 1 a and is conveyed via rollers 2, 3 to a pre-combing drum 4, in which the fiber fluff is debonded in a first stage until it becomes individual fibers and are orie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com