Fuel additive preparation method, and fuel additive and uses thereof

A technology for fuel additives and liquid fuels, which is applied in the directions of fuel additives, fuels, and liquid carbon-containing fuels, can solve the problems of complex preparation methods, high prices, secondary pollution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention at first provides a kind of preparation method of fuel additive, comprises the following steps:

[0034] It is obtained by heating the fermented liquid obtained after fermenting fruit raw materials, and then extracting with a solvent.

[0035] The fruit raw material in the present invention includes unprocessed fruit, processed fruit or residue after fruit juice extraction. As the fruit, there are citrus fruits such as satsuma, satsuma, satsuma, iyokan, sambogan, navel orange, yuzu, ponkan, chrysanthemum, late white pomelo, grapefruit, hassaku, lemon, lime, More than one kind of pomelo and kumquat; more than one kind of pome fruit, such as apple, pear, loquat, quince, and persimmon; stone fruit, such as one of peach, plum, apricot, plum, cherry, and jujube Above; berry fruits, such as one or more of grapes, raspberries, figs, gooseberries, pineapples, bananas; coconut fruits.

[0036] Fruit processed products refer to a wide range of processed fr...

Embodiment 1

[0055] Add sucrose to 200L of fruit juice squeezed from Satsuma citrus, adjust the sugar content to 25 ° Be, obtain the product to be fermented after adjusting the sugar content, take 2L of the product to be fermented after the above-mentioned adjusted sugar content, as the product to be fermented I, add Saccharomyces cerevisiae ellipse to it (Saccharomyces cerevisiae var. ellipsoideus) strain (this strain is deposited in IFO, IFO No.0213, and is recorded in the catalog of IFO as a permanent preservation strain, and can be sold separately) is passed through at 27°C Cultivate with air stirring for 24 hours to obtain a culture solution for preliminary fermentation.

[0056] Afterwards, take 18L of the above-mentioned product to be fermented after adjusting the sugar content, as the product to be fermented II, add it to the fermenter, add 1.8L of the above-mentioned culture solution for preliminary fermentation, feed air at 27°C, and stir and cultivate for 24 hours to obtain The ...

Embodiment 2

[0059] Replace Satsuma citrus with grapes, in addition, in the nutrient solution of Saccharomyces cerevisiae ellipsoid strain IFO No.0021, add potassium metabisulfite 0.15wt% (in total weight of nutrient solution) as bactericide, according to the method identical with embodiment 1 Processed to obtain a combustion enhancer containing 1wt% active ingredient, which is designated as fuel additive II.

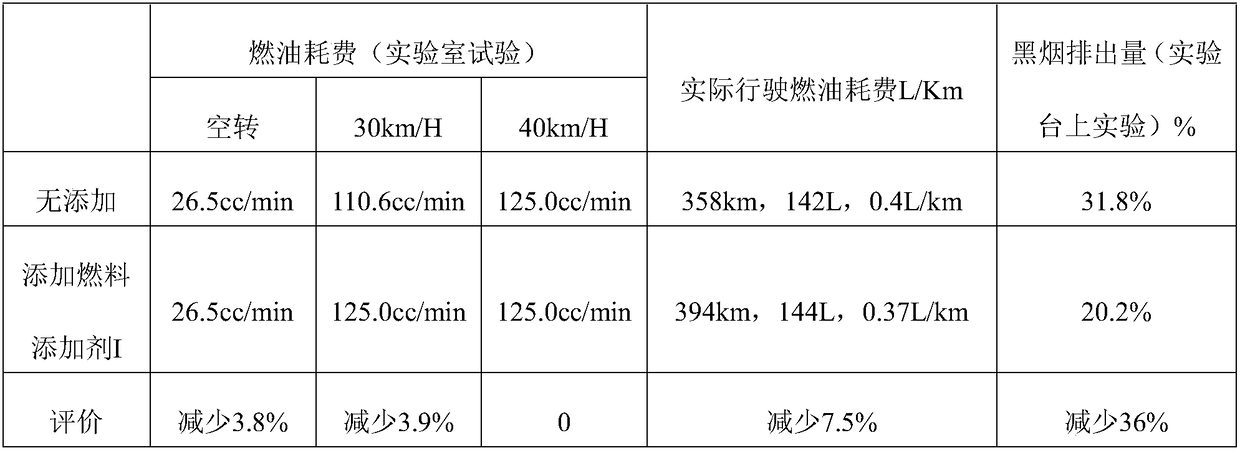

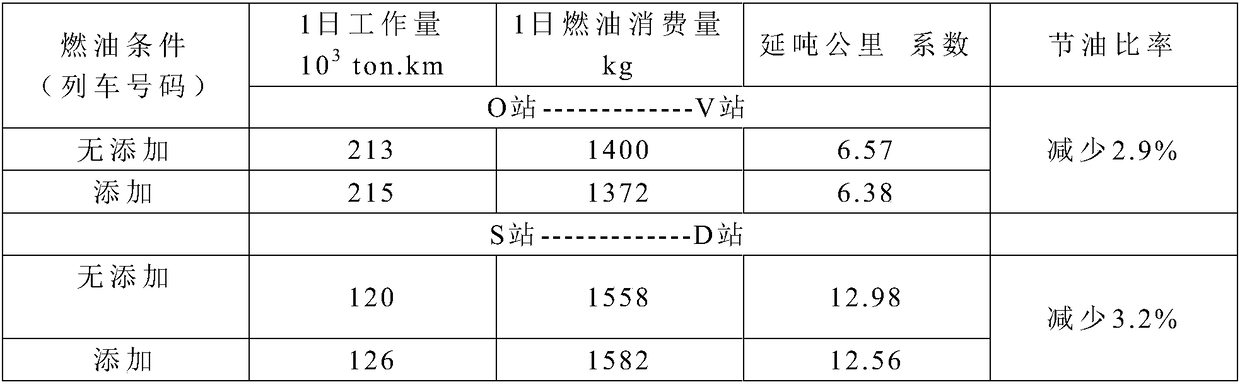

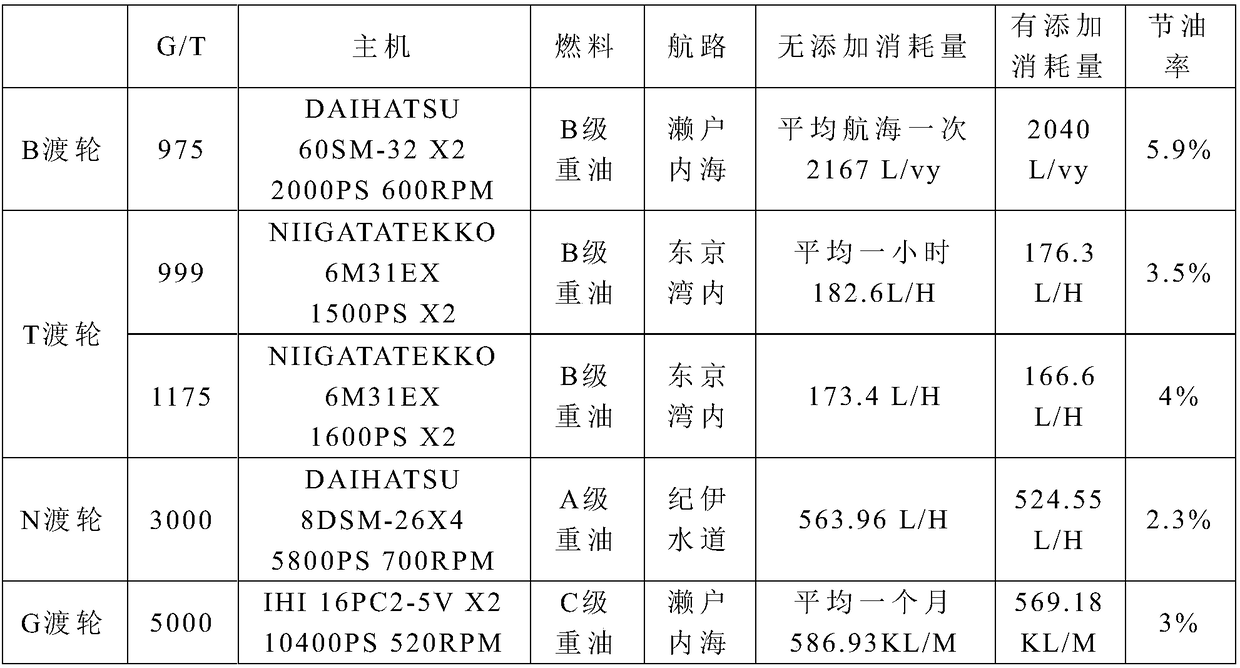

[0060] Performance Evaluation of Fuel Additives

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com