A kind of water-in-oil drilling fluid and preparation method thereof

A water-in-oil based drilling fluid technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor suspension capacity and high temperature resistance, increased filtration loss, high oil solubility, etc., to achieve Improve yield and stability, improve compactness, reduce the effect of high temperature and high pressure filtration loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

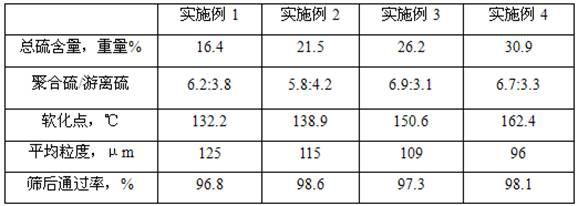

Embodiment 1

[0045] Add 425g of oxidized asphalt with a softening point of 128.6°C to water, crush it with a high shear machine for 20 minutes, then add 10.6g of fatty alcohol polyoxyethylene ether (AEO-7) and 0.15g of diisopropyl xanthate disulfide , to obtain bituminous liquid; heat 75g of sulfur to 130°C, and after 15 minutes, heat to 520°C, while feeding N 2 , keep the pressure at 1.0MPa for 60 minutes to form polymerized sulfur vapor. Spray polymerized sulfur steam into the above asphalt liquid to form asphalt particles coated with modifier and suspend in the asphalt liquid, keep at 20°C for 40 minutes to fully stabilize and solidify, then dehydrate and dry. The obtained solid is sieved with a vibrating sieve to obtain modified asphalt granules.

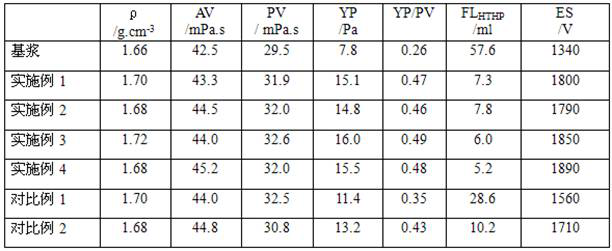

[0046] Prepare drilling fluid according to oil-water ratio (80:20): First, measure 800ml 3# white oil with a measuring cylinder, add 0.8 parts of lauroyldiethanolamine, stir for 15 minutes, add 1.5 parts of organic soil, and stir for 5 minu...

Embodiment 2

[0048] Add 400g of oxidized asphalt with a softening point of 134.8°C to water, crush it with a high shear machine for 25 minutes, then add 13.2g of octadecylamine polyoxyethylene ether and 0.1g of isopropanol to obtain asphalt liquid; heat 100g of sulfur to 135 ℃, heated to 550℃ after 10 minutes, while feeding N 2 , keep the pressure at 1.6MPa for 50 minutes to form polymerized sulfur vapor. Spray polymerized sulfur steam into the above asphalt liquid to form asphalt particles coated with modifier and suspend in the asphalt liquid, keep at 25°C for 60 minutes to fully stabilize and solidify, then dehydrate and dry. The obtained solid is sieved with a vibrating sieve to obtain modified asphalt granules.

[0049] Prepare the drilling fluid according to the oil-water ratio (65:35): First, measure 650ml of 5# white oil with a graduated cylinder, add 0.2 parts of polyoxyethylene stearate, stir for 20 minutes, add 1.0 parts of organic soil, and stir for 10 minutes. Mix 25% calciu...

Embodiment 3

[0051] Add 375g of oxidized asphalt with a softening point of 145.8°C to water, crush it with a high shear machine for 25 minutes, then add 17.6g of alkylphenol polyoxyethylene ether (OP-10) and 0.25g of 4-chloro-1-butanol, To obtain asphalt liquid; heat 125g of sulfur to 145°C, and then heat to 540°C after 15 minutes, while feeding N 2 , and keep the pressure at 1.5MPa for 45 minutes to form polymerized sulfur vapor. Spray polymerized sulfur steam into the above asphalt liquid to form asphalt particles coated with modifier and suspend in the asphalt liquid, keep at 30°C for 50 minutes to fully stabilize and solidify, then dehydrate and dry. The obtained solid is sieved with a vibrating sieve to obtain modified asphalt granules.

[0052] Prepare the drilling fluid according to the oil-water ratio (70:30): First, measure 700ml of 5# white oil with a graduated cylinder, add 0.6 parts of oleoyldiethanolamine, stir for 15 minutes, add 1.6 parts of organic soil, and stir for 10 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com