Mixed sewage short-range treatment system and method

A mixed sewage and treatment system technology, which is applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. It is rare to be able to solve the combined treatment of oily sewage in multiple states , large dosage and other issues, to achieve the effect of easy maintenance and management, stable and reliable operation, and reasonable cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

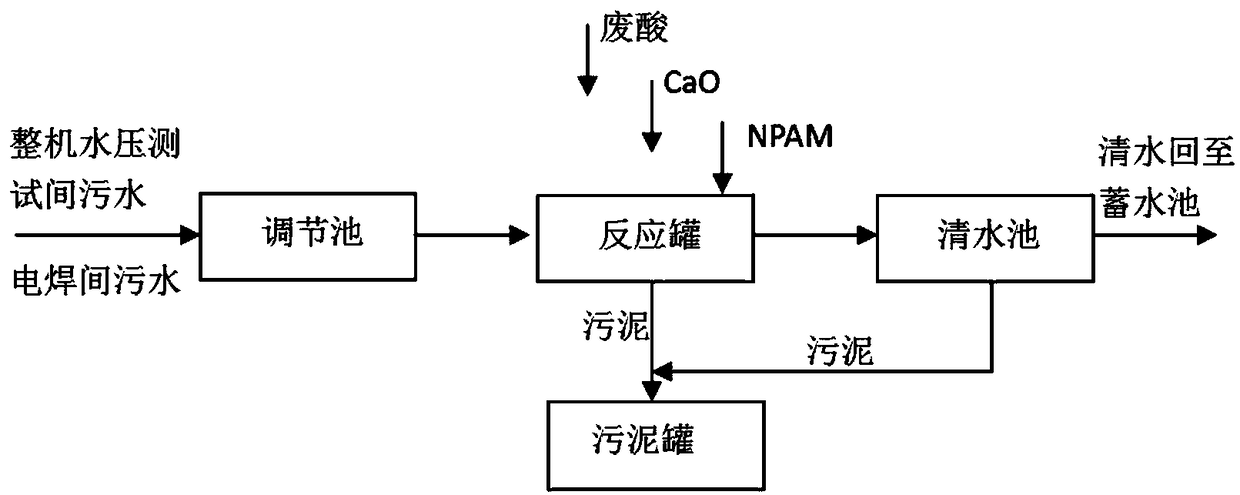

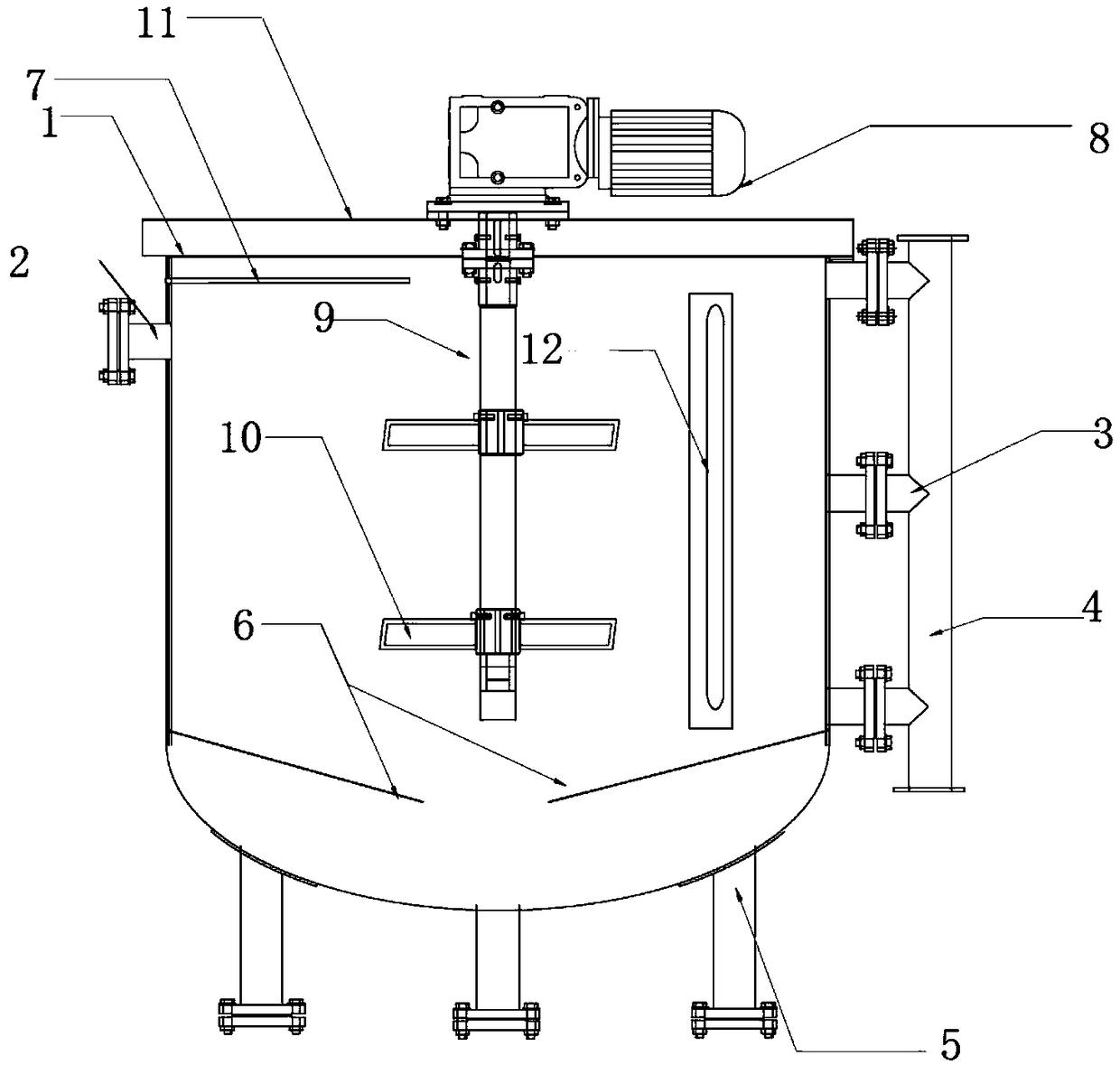

[0046] A short-range treatment method for mixed sewage, comprising the steps of:

[0047] Step 1. Initial sedimentation: The sewage from the electric welding room of the filter press and the hydraulic test room of the whole machine flow into the adjustment tank together. After the initial sedimentation in the adjustment tank, the sewage is pumped into the reaction tank with a submersible sewage pump.

[0048] Step 2. Acidification and demulsification: Add 2g / L waste acid into the reaction tank, stir rapidly at a speed of 150r / min, stir until the sewage in the reaction tank turns from yellow to white, continue stirring for 5 minutes, then stop stirring, and the pH reaches 2-3 , after stirring, let it stand for 5 minutes; wherein, the waste acid comes from industrial pickling waste liquid, the pH is 1.5, contains 12wt% ferrous chloride, 20wt% sulfuric acid, and the organic matter concentration is less than or equal to 50mg / L.

[0049] Step 3, coagulation: add 0.5g / L calcium oxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com