Tire

A tire and tire circumferential technology, applied to tire parts, tire tread/tread pattern, transportation and packaging, etc., can solve the problems of noise performance deterioration, large air vibration, etc., to improve mud performance and mud performance Improved performance and high noise performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

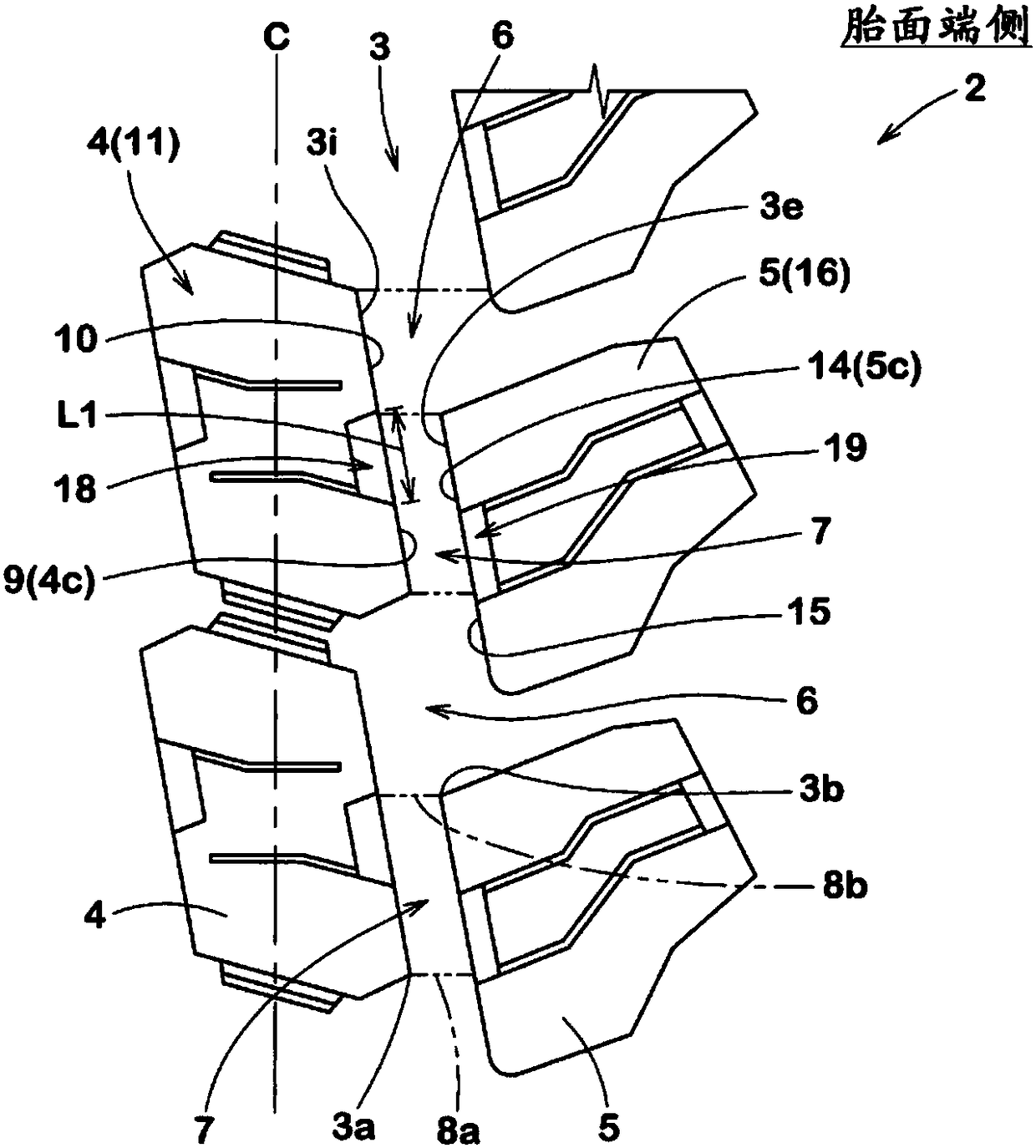

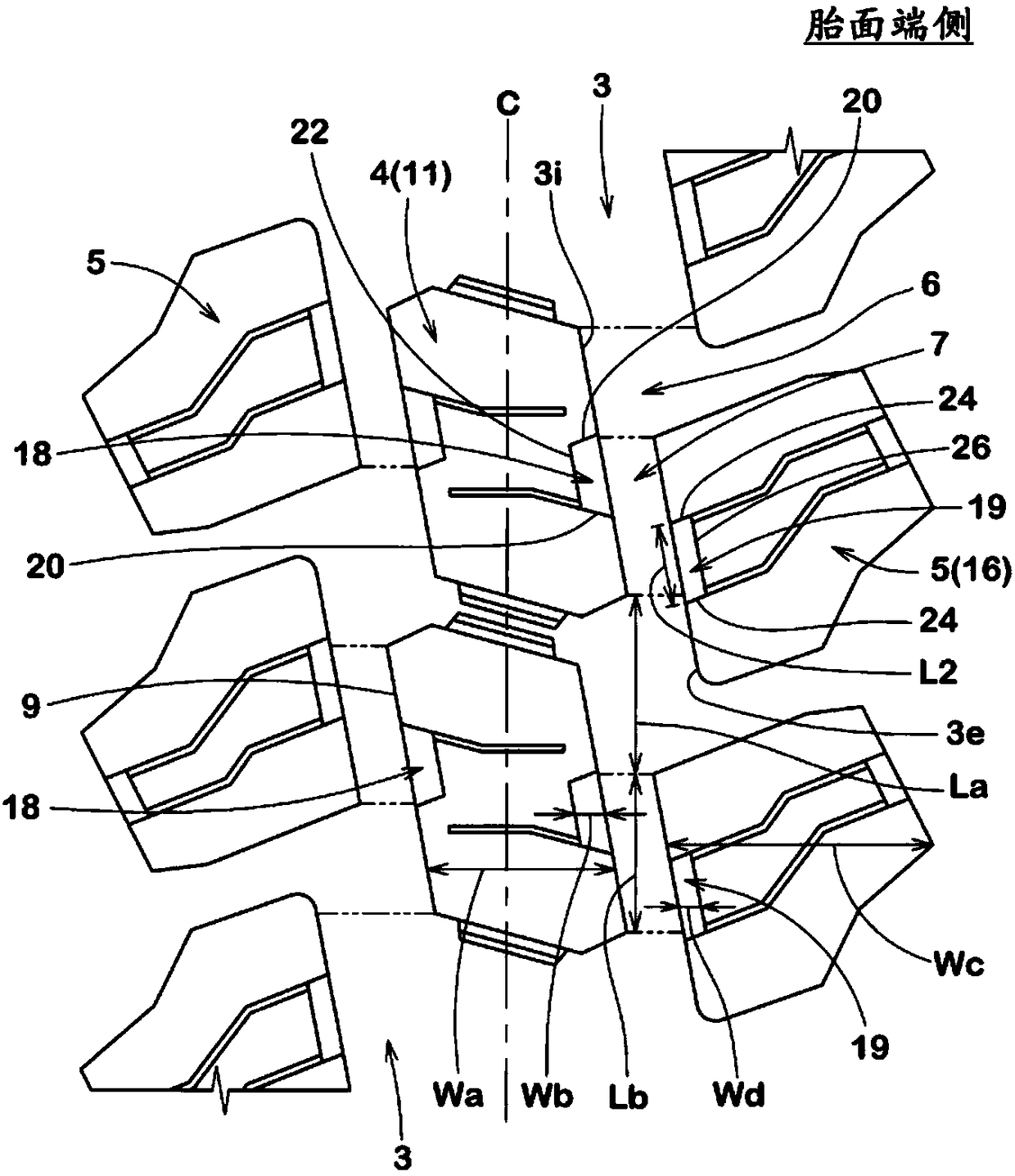

[0079] Prototyped according to the specifications in Table 1 with figure 1 The tires for four-wheel drive vehicles with the basic pattern size 265 / 70R17 were tested, and the mud performance, noise performance, handling stability and wet performance of each tire were tested. The main common specifications and test methods of each test tire are as follows.

[0080] The depth d1 of the main groove: 10.5mm

[0081]

[0082] Each test tire was mounted on all wheels of a four-wheel drive vehicle with a displacement of 5300 cc under the following conditions. Then, the test driver drove the car on each test track formed of a soft road surface formed of mud (depth 30 cm), a dry asphalt road surface, and a wet asphalt road surface. Furthermore, the test driver sensory evaluated running characteristics related to traction, running stability, and cornering performance at this time. The results are shown using a score with Comparative Example 1 as 100. The higher the value, the bette...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com