Pneumatic tire

A technology of pneumatic tires and tires, which is applied in the direction of off-road vehicle tires, tire parts, tire treads/tread patterns, etc., which can solve the problems of easy decline in wear resistance and improve block rigidity and partial wear resistance , well-balanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

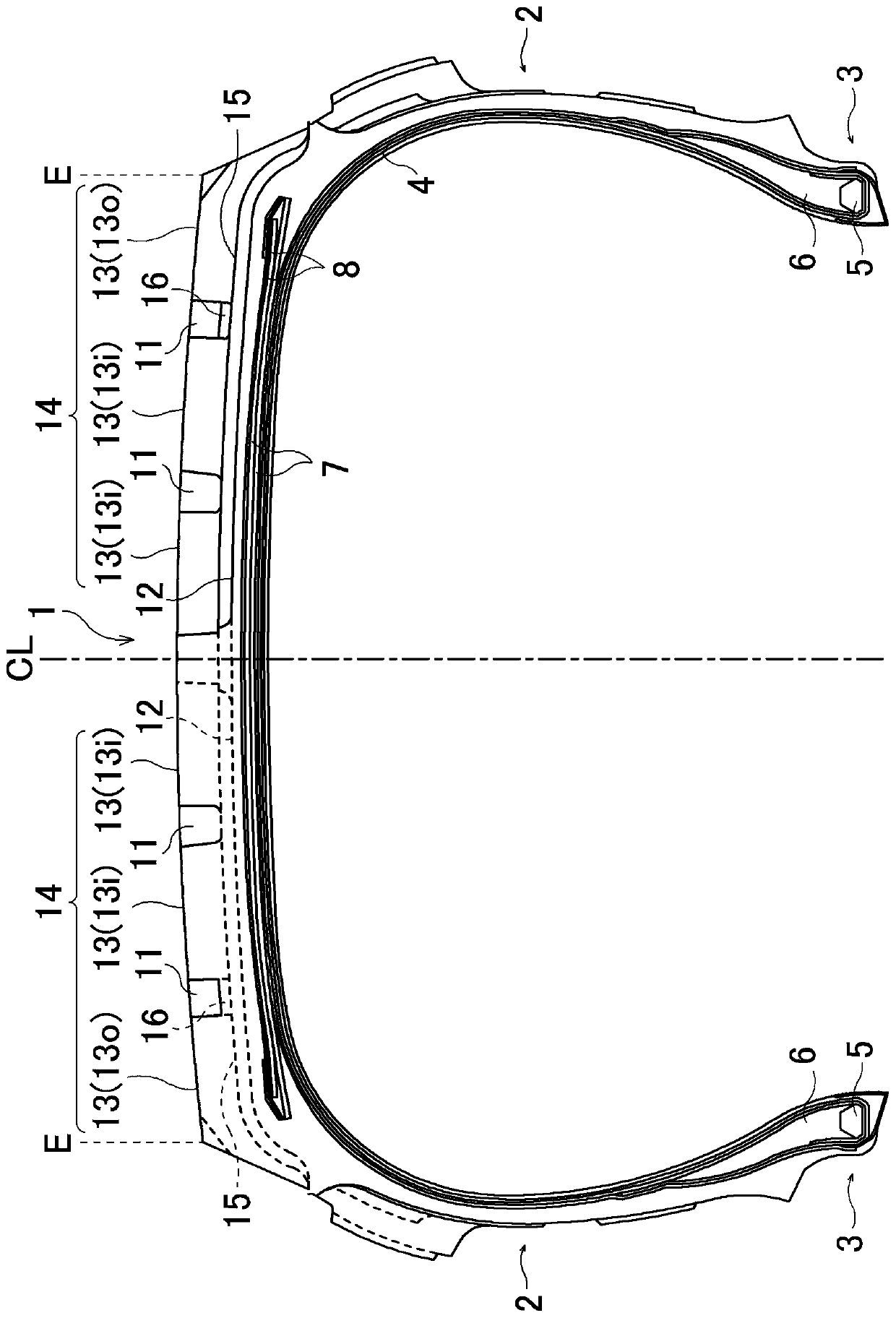

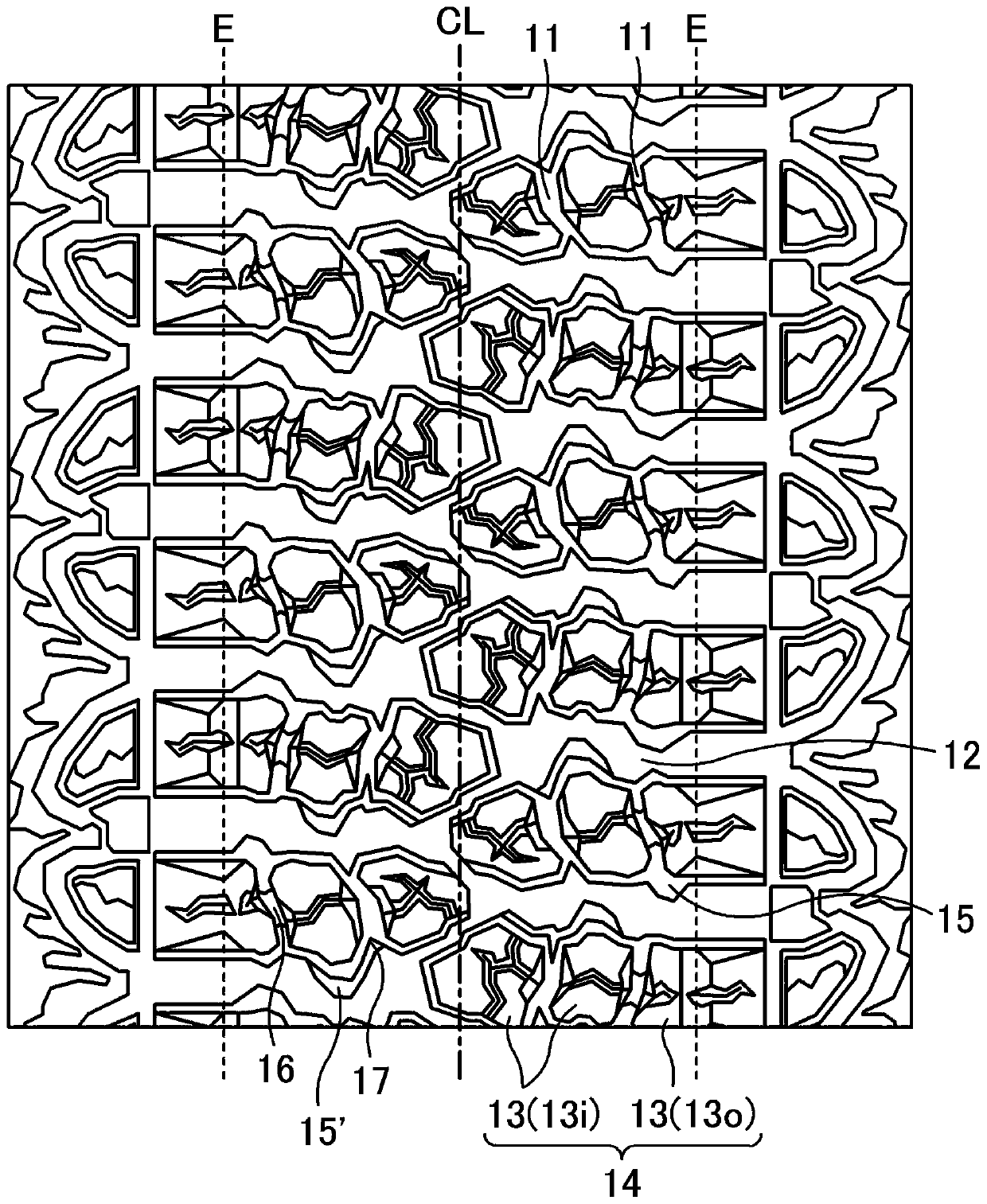

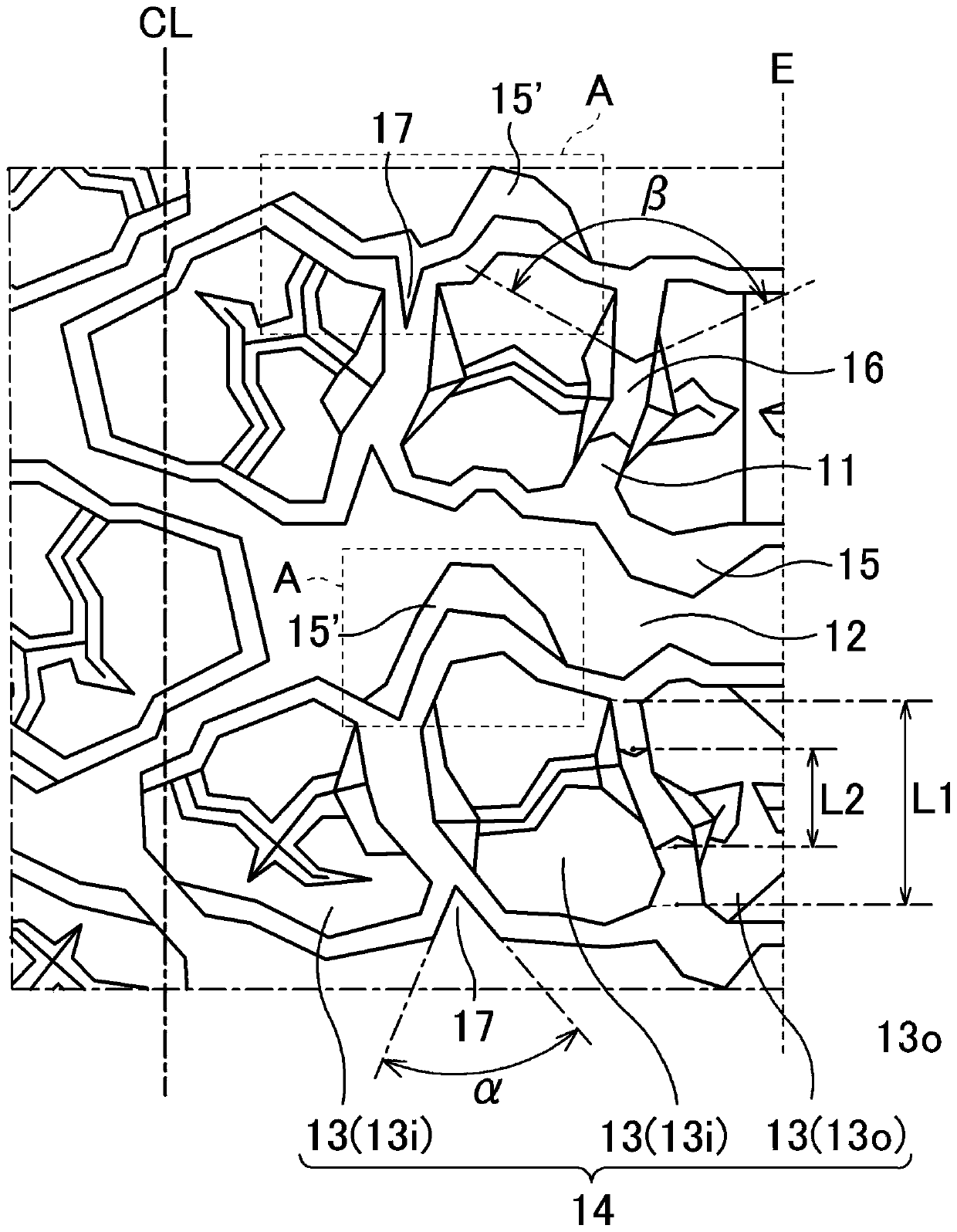

[0046] 27 kinds of pneumatic tires of the following conventional example 1, comparative example 1, and examples 1 to 25 were produced: the tire size was 35×12.50R17 and had figure 1 The basic structure of the example and the figure 2 The tread pattern is the keynote, and, regarding the platform, the number of blocks existing on the platform, the ratio of the raised height H1 of the platform to the maximum groove depth GD1 of the transverse groove (the ratio of the raised height), and the total The ratio of the area to the projected area of the platform (the ratio of the area), whether it has a shape that protrudes to both sides of the tire circumferential direction relative to the block (the presence or absence of circumferential protrusion), whether there is a groove between the bottom of the transverse groove and the top of the platform The stepped structure with a step between the surfaces (the presence or absence of the stepped structure), the presence or absence of a V...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com