Numerical control solid wood cutting, milling and sawing machine

A technology of solid wood and sawing machine, which is applied in the field of wood processing, and can solve the problems of users' troubles, the inability to effectively discharge wood chips, and the sticking of wood chips to the blade, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

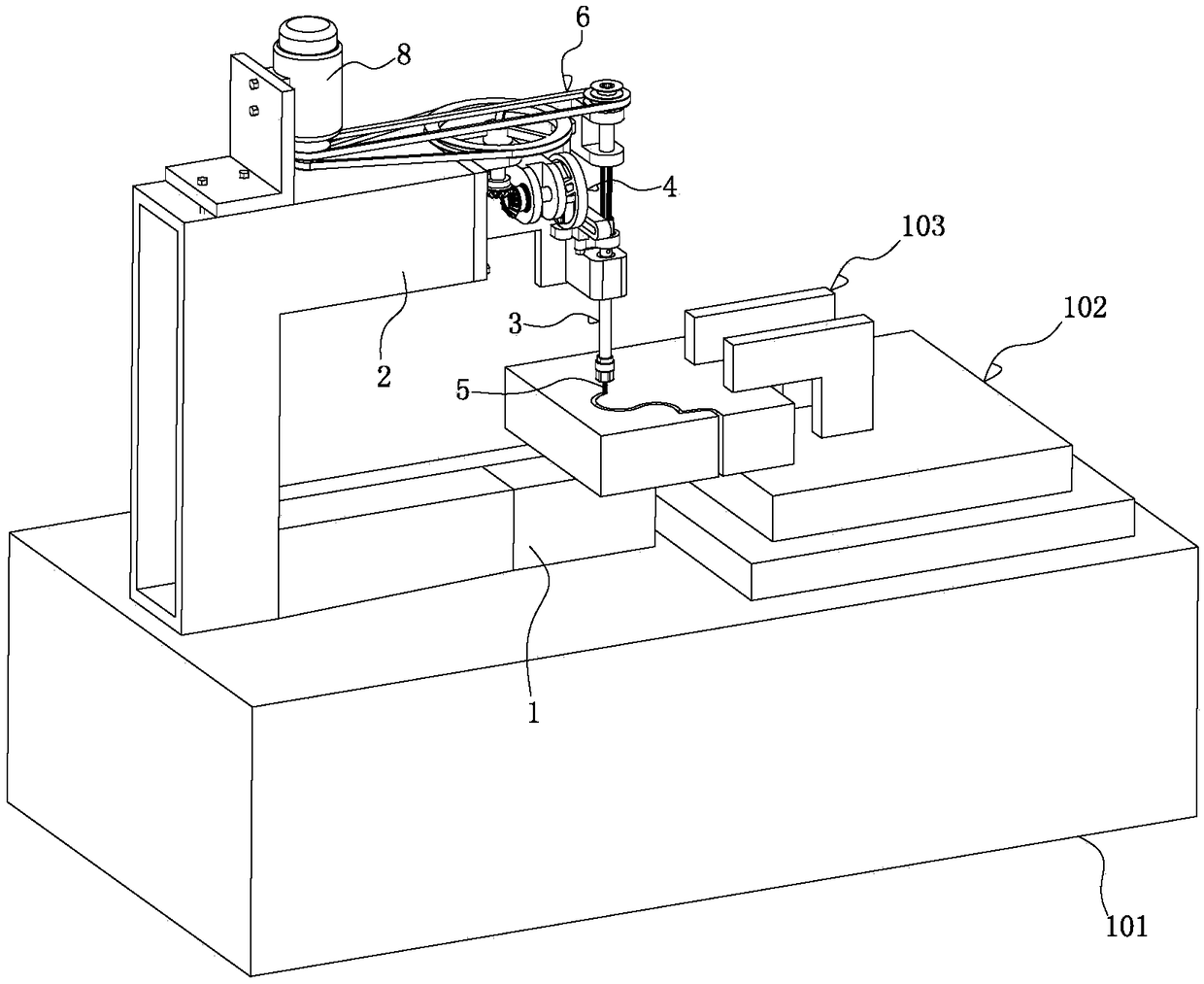

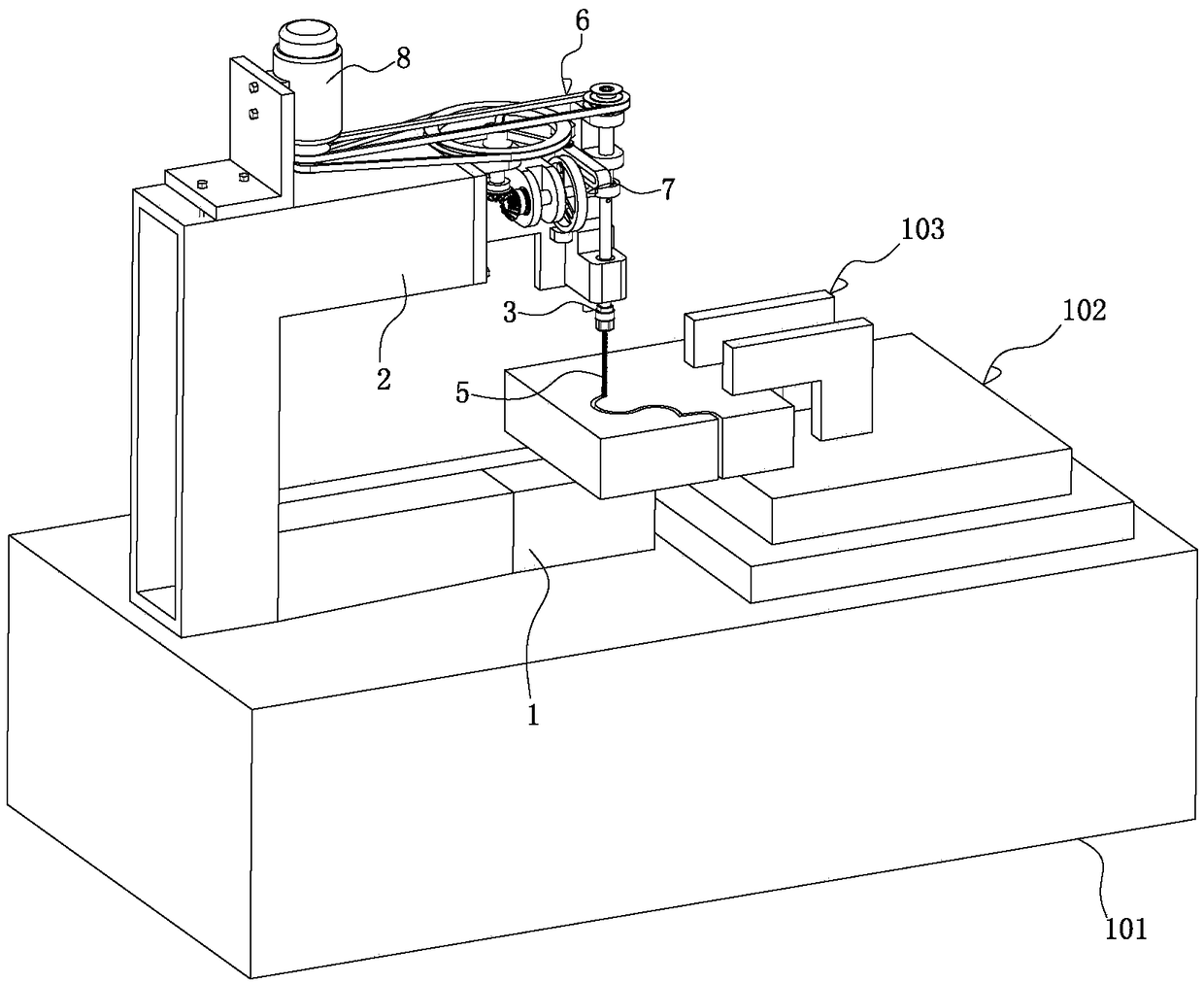

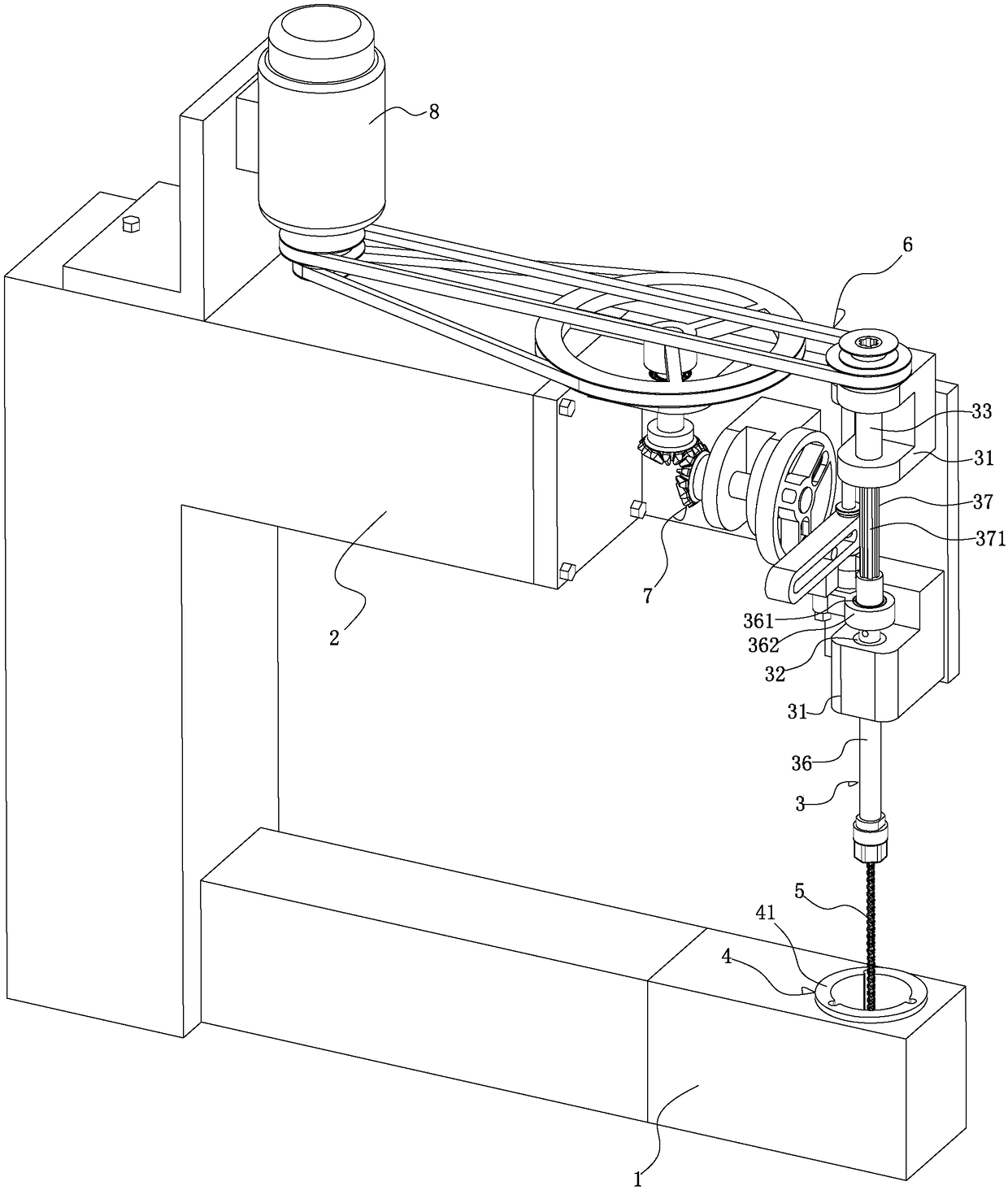

[0024] See Figure 1-6 As shown, it is a CNC solid wood milling and sawing machine, which includes: a base 1 and a machine head 2 installed on the base 1, a spindle module 3 installed on the machine head 2, and a rotatable Up and down sliding module 4, a cylindrical milling saw blade 5 fixedly installed between the main shaft module 3 and the rotatable up and down sliding module 4, a rotary drive installed on the head 2 and used to drive the main shaft module 3 to rotate The mechanism 6 and the up and down sliding drive mechanism 7 installed on the machine head 2 and used to drive the spindle module 3 to move back and forth up and down, the rotary drive mechanism 6 and the up and down sliding drive mechanism 7 share a motor 8 as a power device. When the present invention works, since the cylindrical milling saw cutter 5 is fixedly installed betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com