Shape memory alloy driven electrostatic adsorption flexible gripper

A technology of memory alloy and electrostatic adsorption, which is applied in the direction of manipulators, manufacturing tools, chucks, etc., can solve the problems of high impact force of movement, poor flexibility, and complexity, so as to achieve enhanced bonding effect, good work adaptability, and excellent Effect of Flexibility and Anti-Fatigue Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

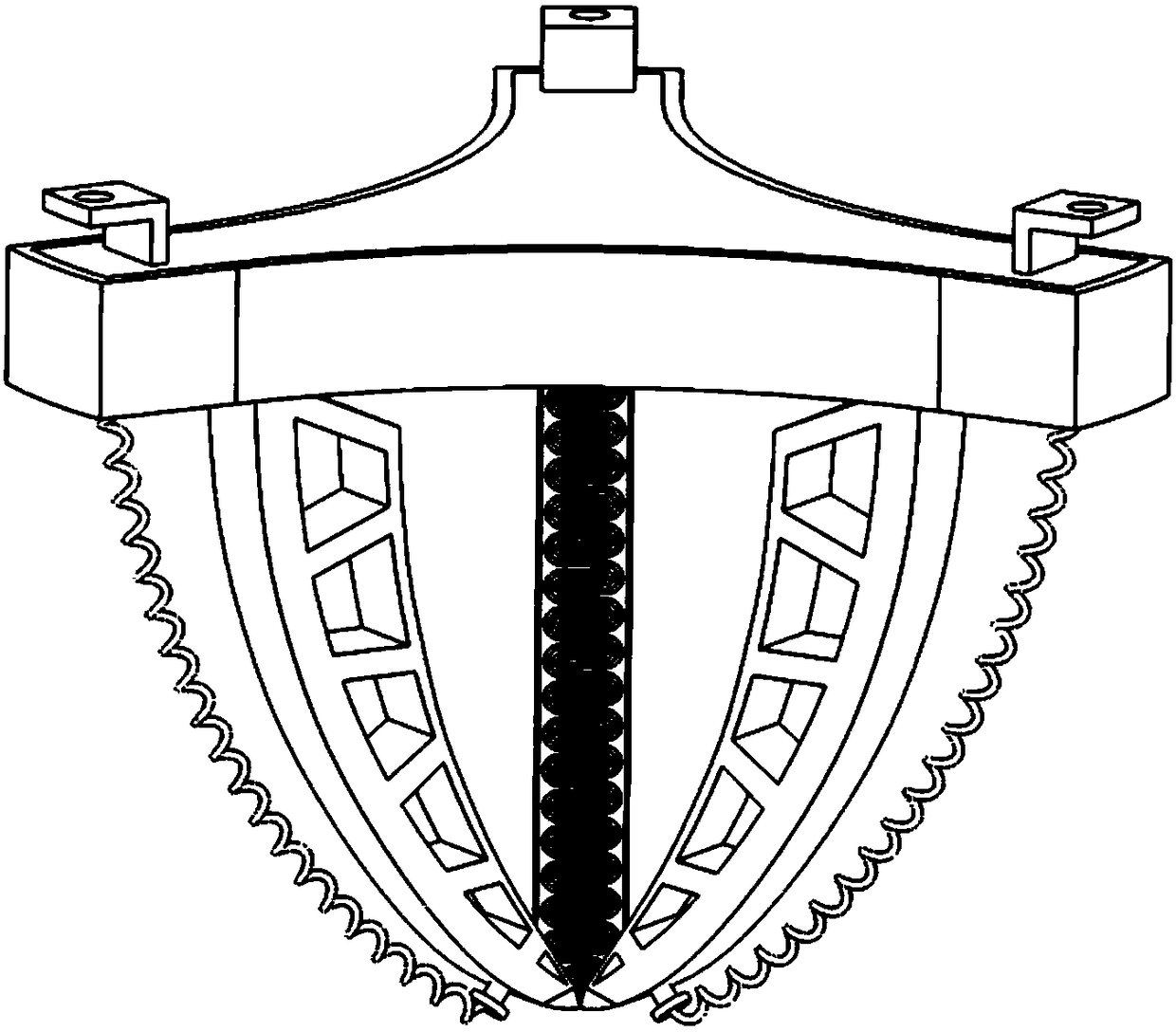

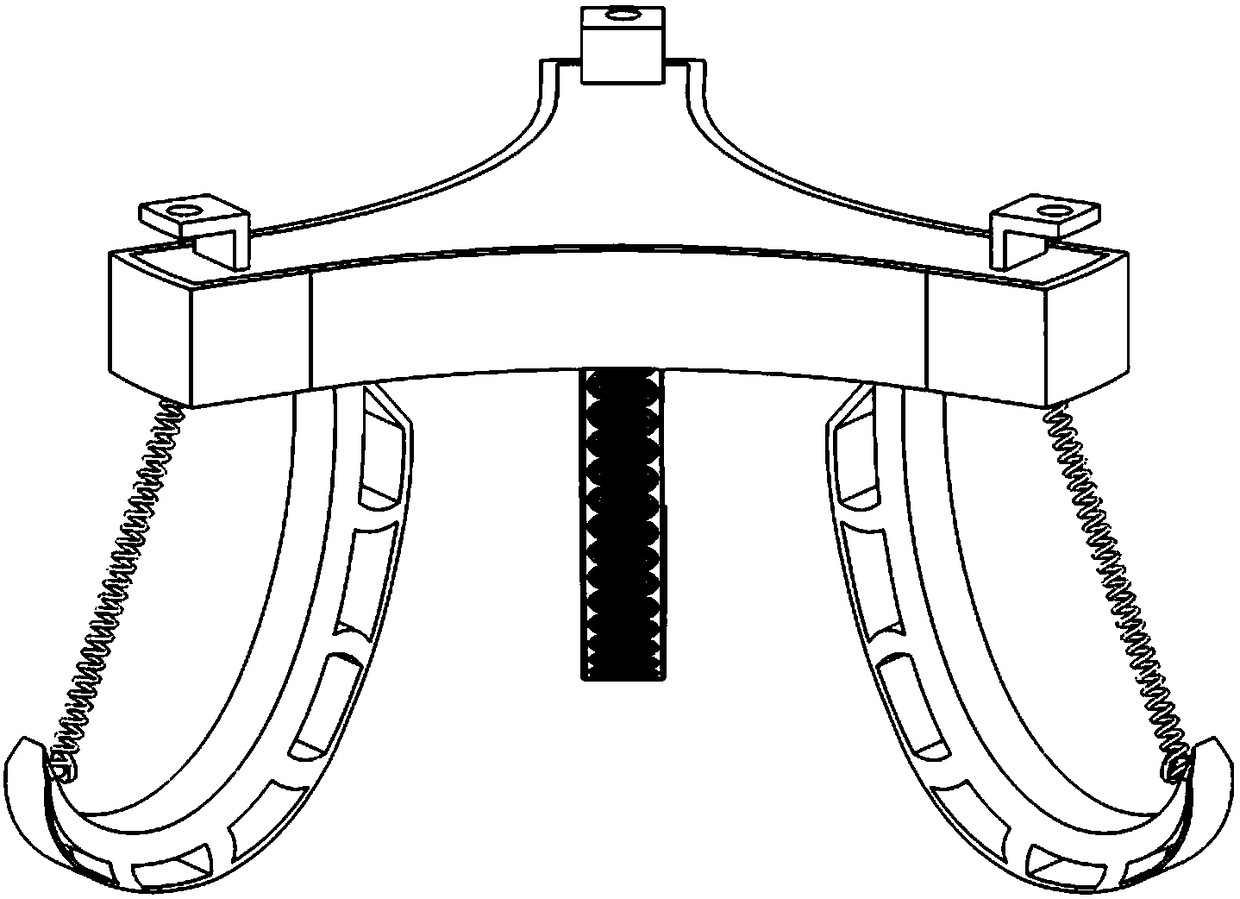

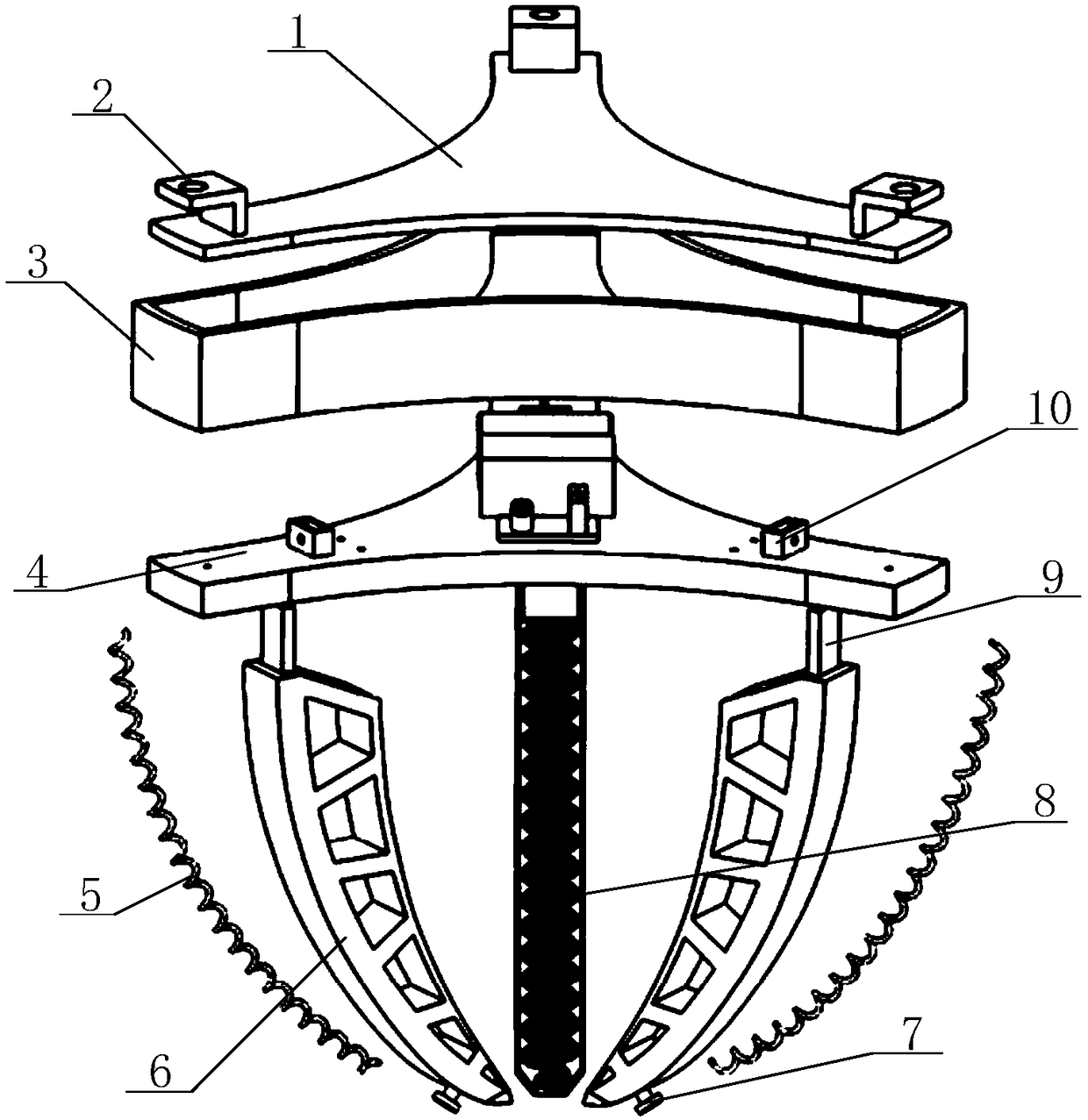

[0029] figure 1 It is a schematic diagram of the structure of the present invention, as shown in the figure: a shape memory alloy-driven electrostatic adsorption flexible gripper, including a palm base, a plurality of elastic fingers arranged on the palm base, and one-to-one correspondingly connected to the elastic fingers SMA spring 5; each of the elastic fingers is closed in a free state; after the SMA spring 5 is energized, each of the elastic fingers connected to it can be pulled outward to open the elastic fingers; the elastic fingers can adopt any existing form, A material or structure with strong elastic deformation ability. When the SMA spring 5 is energized, the current heats the spring, causing the SMA spring 5 to contract and pull the elastic fingers to bend, so that the gripper can be opened; when a low duty cycle or zero duty is applied After the specific voltage, the SMA spring 5 is released, and the elastic fingers are restored, so that the grip is closed.

[0030...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com