A method for oxygen-increased combustion of pulverized coal mixed with biomass

A biomass and admixture technology, which is applied in combustion methods, combustion using lump fuel and powder fuel, combustion equipment, etc. The problem of large difference in characteristics, etc., can reduce the loss of exhaust gas, increase the oxygen content, and reduce the generation amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

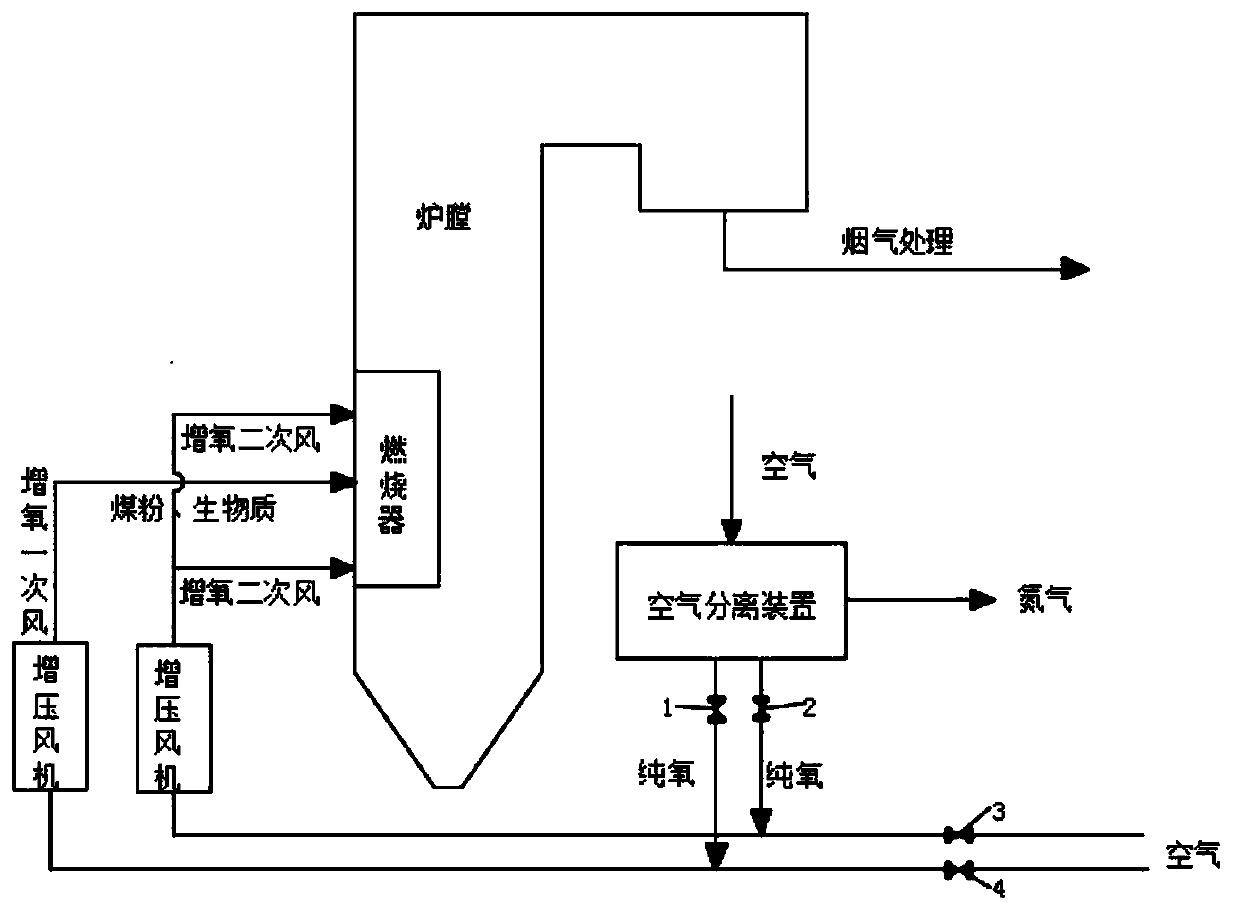

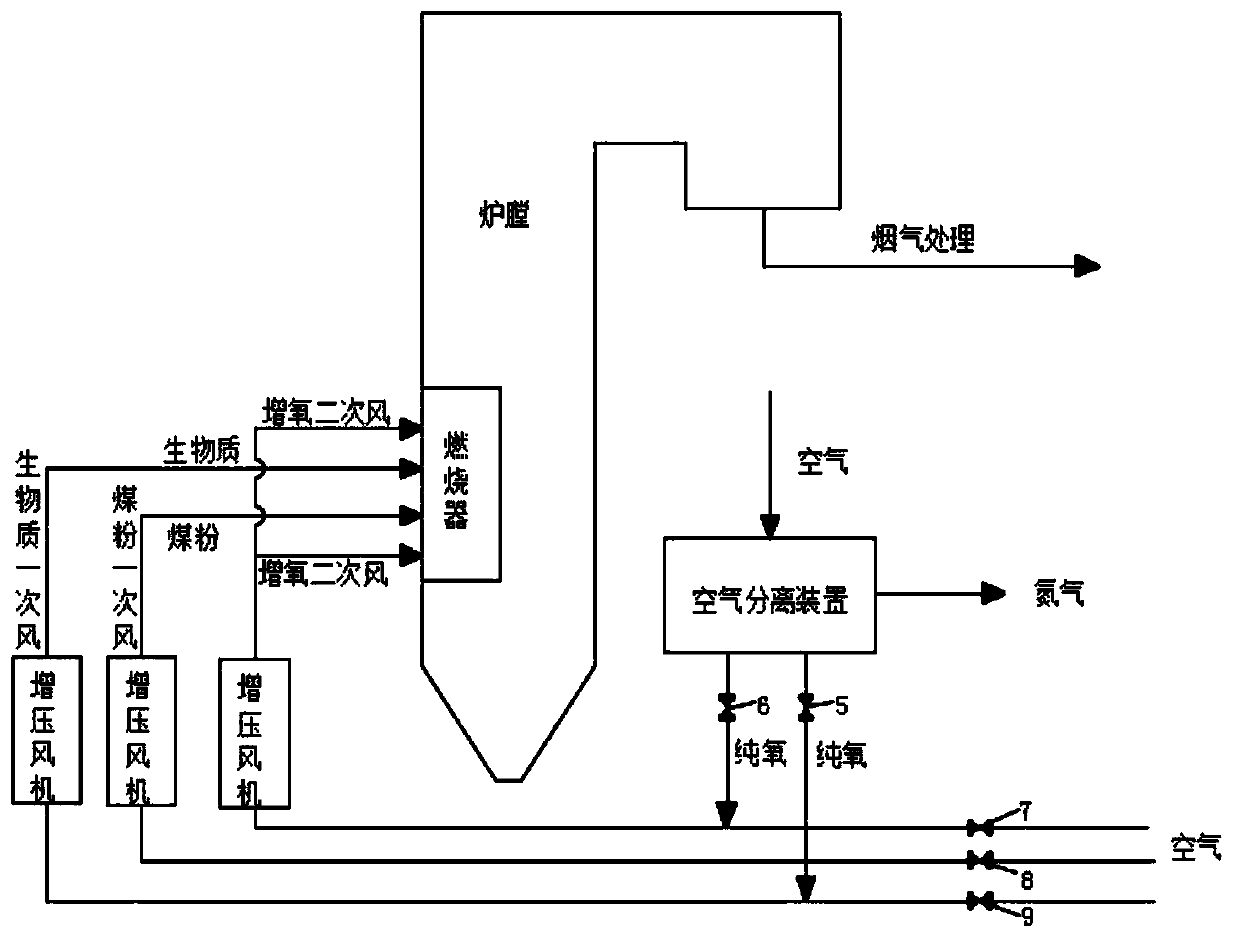

Embodiment 1

[0023] Biomass and coal powder are pre-mixed to form a blend before entering the furnace, and the calorific value ratio of biomass and coal powder is 1:5. The admixture is used as fuel and injected into the furnace by the oxygen-increased primary air. The oxygen content of the oxygen-increased primary air is 22%, the oxygen content of the oxygen-increased secondary air is 22%, and the excess air coefficient in the furnace is 1.1. The oxygen entering the furnace The volume flow accounts for 22% of the total gas volume flow entering the furnace.

Embodiment 2

[0025] Biomass and coal powder are pre-mixed to form a blend before entering the furnace, and the calorific value ratio of biomass and coal powder is 1:4. The mixture is used as fuel and injected into the furnace by the oxygen-increased primary air. The oxygen content of the oxygen-increased primary air is 27%, the oxygen content of the oxygen-increased secondary air is 23%, and the excess air coefficient in the furnace is 1.05. The oxygen entering the furnace The volume flow accounts for 24% of the total gas volume flow into the furnace.

Embodiment 3

[0027] The biomass and pulverized coal are pre-mixed to form a blend before entering the furnace, and the calorific value ratio of biomass and pulverized coal is 3:10. The admixture is used as fuel and injected into the furnace by the oxygen-increased primary air. The oxygen content of the oxygen-increased primary air is 30%, the oxygen content of the secondary air is 26%, the excess air coefficient in the furnace is 1, and the oxygen volume flow rate entering the furnace It accounts for 26% of the total gas volume flow into the furnace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com